Equipment manufacturer JCB plans to invest €179.5 million (£150 million) in its manufacturing facilities in the UK. The investment will be targeted at its operations in Staffordshire and this will add some 2,500 to the firm’s payroll by 2018. This in turn is expected to add a further 7,500 jobs in the UK component supply chain. This investment represents the single largest investment in JCB’s history and includes a brand-new purpose-built factory for JCB Cab Systems in Beamhurst, near Uttoxeter, to replace

December 6, 2013

Read time: 2 mins

Equipment manufacturer 255 JCB plans to invest €179.5 million (£150 million) in its manufacturing facilities in the UK. The investment will be targeted at its operations in Staffordshire and this will add some 2,500 to the firm’s payroll by 2018. This in turn is expected to add a further 7,500 jobs in the UK component supply chain. This investment represents the single largest investment in JCB’s history and includes a brand-new purpose-built factory for JCB Cab Systems in Beamhurst, near Uttoxeter, to replace the current smaller facility in Rugeley. It will also enable JCB to in-source production of cabs currently made by third party suppliers in Europe. JCB’s production operations in Rocester will be increased to boost hydraulic cylinder production. A new, purpose-built factory will be erected on the Harewood Industrial Estate in Cheadle, Staffordshire to expand existing JCB Earthmovers and JCB Compact Products operations, allowing JCB Utility Products to relocate to this site from the current smaller factory elsewhere in the town. The existing JCB Finance and JCB Insurance offices in Rocester will be relocated to new purpose-designed, high-quality office accommodation at nearby Harper Meadow in Denstone. There will also be a new in-house training facility for JCB staff, to be run in conjunction with key universities to support apprenticeship and graduate training programmes. All of these new facilities will be subject to planning consent.

Lord Bamford said, “Our plan to create 2,500 high-quality manufacturing jobs locally is clear evidence of the important link between infrastructure improvement and job creation.”

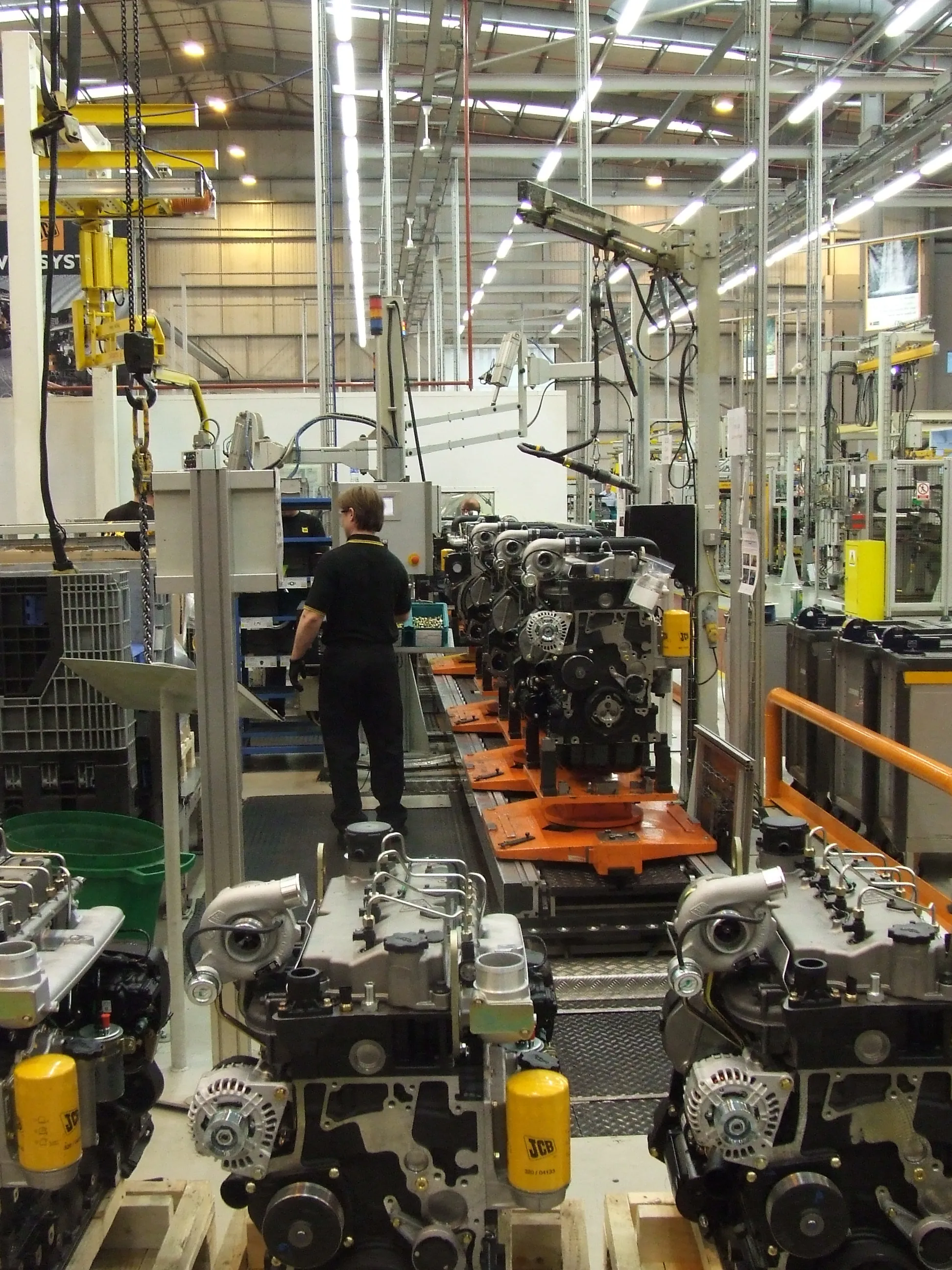

The projected growth in machine output from Staffordshire factories will be supported by an increase in production of components from factories elsewhere in the UK, including engines from JCB Power Systems in Foston, Derbyshire, and axles and gearboxes from JCB Transmissions in Wrexham, North Wales.

Lord Bamford said, “Our plan to create 2,500 high-quality manufacturing jobs locally is clear evidence of the important link between infrastructure improvement and job creation.”

The projected growth in machine output from Staffordshire factories will be supported by an increase in production of components from factories elsewhere in the UK, including engines from JCB Power Systems in Foston, Derbyshire, and axles and gearboxes from JCB Transmissions in Wrexham, North Wales.