Case, in conjunction with Hyundai, has launched a four-model E-Series wheeled excavator range, with a fifth, larger model to join in the future.

The cooperation between Case Construction Equipment and South Korean manufacturer Hyundai Construction Equipment comes from an existing supply partnership, says Case.

The wheeled excavator line-up will include the conventional tail swing WX140E and WX160E, along with the short radius WX155E SR and the WX175E SR. These four models will be joined by a conventional tail swing WX210E at a later stage.

Features include Bosch Rexroth Load Independent Flow Sharing hydraulic systems on the four smaller models as well as heavy-duty ZF axles and hydrostatic transmissions. Enhanced site safety is thanks to large operator cab with CASE Maximum View Monitor enabling 360° view cameras and additional rear radar.

The units operate on a range of bio fuels and synthetic fuels thanks to Cummins Stage V diesel engines with no requirement for exhaust gas re-circulation (EGR) Customisable specification.

They will be available in a range of lower frame layouts, with several combinations of front and rear dozer blades plus front and rear outriggers. Upper equipment will comprise a choice of mono or two-piece main booms for all machines except the WX175E SR which will have only a two-piece articulating boom.

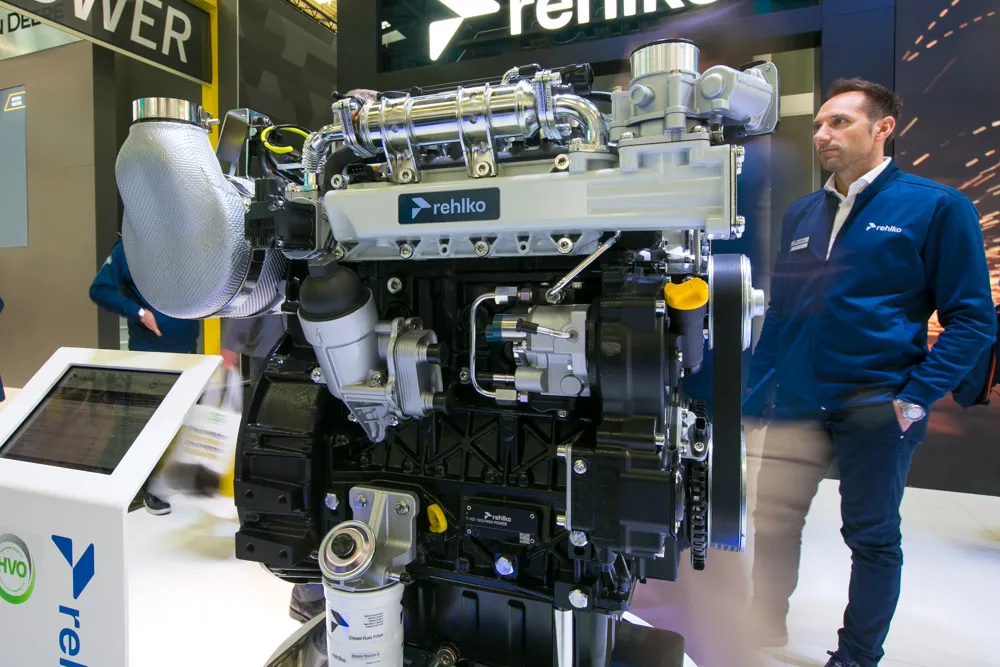

The machines will have cruise control will be standard and be powered by EU Stage V compliant Cummins diesel engines. The four smaller models will use a Cummins B4.5 engine, delivering an above industry standard, outstanding maximum power of 129kW, while the WX210E will come with the larger B6.7, offering up to 145kW maximum power.

The engines feature a highly efficient exhaust aftertreatment module, incorporating a diesel oxidation catalyst (DOC), selective catalytic reduction (SCR) and a diesel particulate filter (DPF). With no need for complex exhaust gas re-circulation (EGR) system to comply with Stage V requirements, the maintenance cost is much reduced. In addition, fuel filter service intervals are 1,000 hours and engine oil and filter intervals are set at 800 hours, further maximizing machine up time for the operator.

Case says that the engines use a range of fuels to suit the customer. This includes B7 and B20 biodiesel, hydrotreated vegetable oils (HVO) and gas-to-liquid (GTL), coal-to-liquids (CTL) biomass-to-liquid (BTL) paraffinic fuels.