The new noise-damped cab for Volvo‘s single drum soil compactors is said to make the machines more comfortable to operate for a full working shift. The comprehensively redesigned one-piece cab is now fitted on Volvo’s latest SD70, SD77, SD115, SD130 and SD160 single drum soil compactors. The noise damping is said to radically reduce the sound levels at the operator’s ear, which is said to cut fatigue levels over the full working shift.

March 14, 2012

Read time: 2 mins

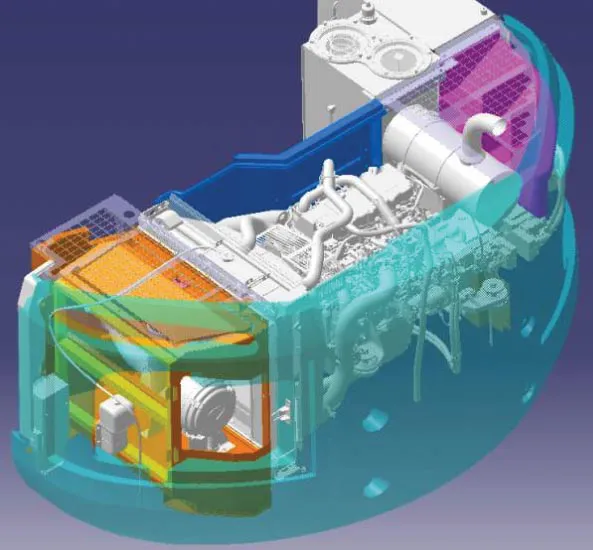

The new noise-damped cab for 2394 Volvo‘s single drum soil compactors is said to make the machines more comfortable to operate for a full working shift. The comprehensively redesigned one-piece cab is now fitted on Volvo’s latest SD70, SD77, SD115, SD130 and SD160 single drum soil compactors. The noise damping is said to radically reduce the sound levels at the operator’s ear, which is said to cut fatigue levels over the full working shift. This new cab is available for the 7-16tonne soil compactors and features a one-piece design that provides effective isolation and insulation from the engine compartment. The sound insulated ROPS protected cabs are mounted on high quality shock absorbers and the design removes the need for any additional sealing or soundproofing to stop engine noise entering the operator compartment. When used with the optional smart power mode, the noise experienced by the operator is further reduced. This special mode optimises engine and hydraulic output as well as the cooling fan speed to match the demands of the working application. The system reduces engine speed and as well as lowering noise, this also cuts fuel consumption, exhaust emissions, wear and maintenance requirements for the machine.

Rugged in design, the Volvo soil compactors are said to deliver high dynamic forces to produce effective compaction and high productivity. With the new cab, the machines can deliver full compaction outut, but without over-tiring the operator.

As well as being quieter, the new cab has a revised layout, with a larger rear window and improved rearwards visibility. The new models also feature air conditioning, while the operator’s seat has additional anti-vibration padding and sits on a smaller pedestal, freeing up more foot space on the floor. The floor itself is completely flat without trip hazards, as well as being easy to sweep out and clean.

Rugged in design, the Volvo soil compactors are said to deliver high dynamic forces to produce effective compaction and high productivity. With the new cab, the machines can deliver full compaction outut, but without over-tiring the operator.

As well as being quieter, the new cab has a revised layout, with a larger rear window and improved rearwards visibility. The new models also feature air conditioning, while the operator’s seat has additional anti-vibration padding and sits on a smaller pedestal, freeing up more foot space on the floor. The floor itself is completely flat without trip hazards, as well as being easy to sweep out and clean.