Italy’s Il Caravaggio International Airport handles close to 9 million passengers/year, making it the country’s fourth busiest. Originally called Bergamo Orio al Serio Airport, it is a popular facility for low cost airlines as it is close to Bergamo and just 40km from Milan, as well as being convenient for other destinations in Northern Italy. In view of the heavy demand the airport’s operator, SACBO, is investing in the facility so as to meet its long-term needs.

A key portion of the project has required resurfacing the entire 3km runway, which has required a three-week closure of the facility. Excavators and wheeled loaders from

The fleet includes New Holland’s top-of-the range E485C crawler excavators, as well as E385C, E265B, E245C and E215C crawler excavators, in addition to a number of mini excavators from the firm’s compact range. The machine fleet also includes a W190 wheeled loader and a W80 wheeled loader. This fleet has been augmented by additional units when required to carry out specific duties.

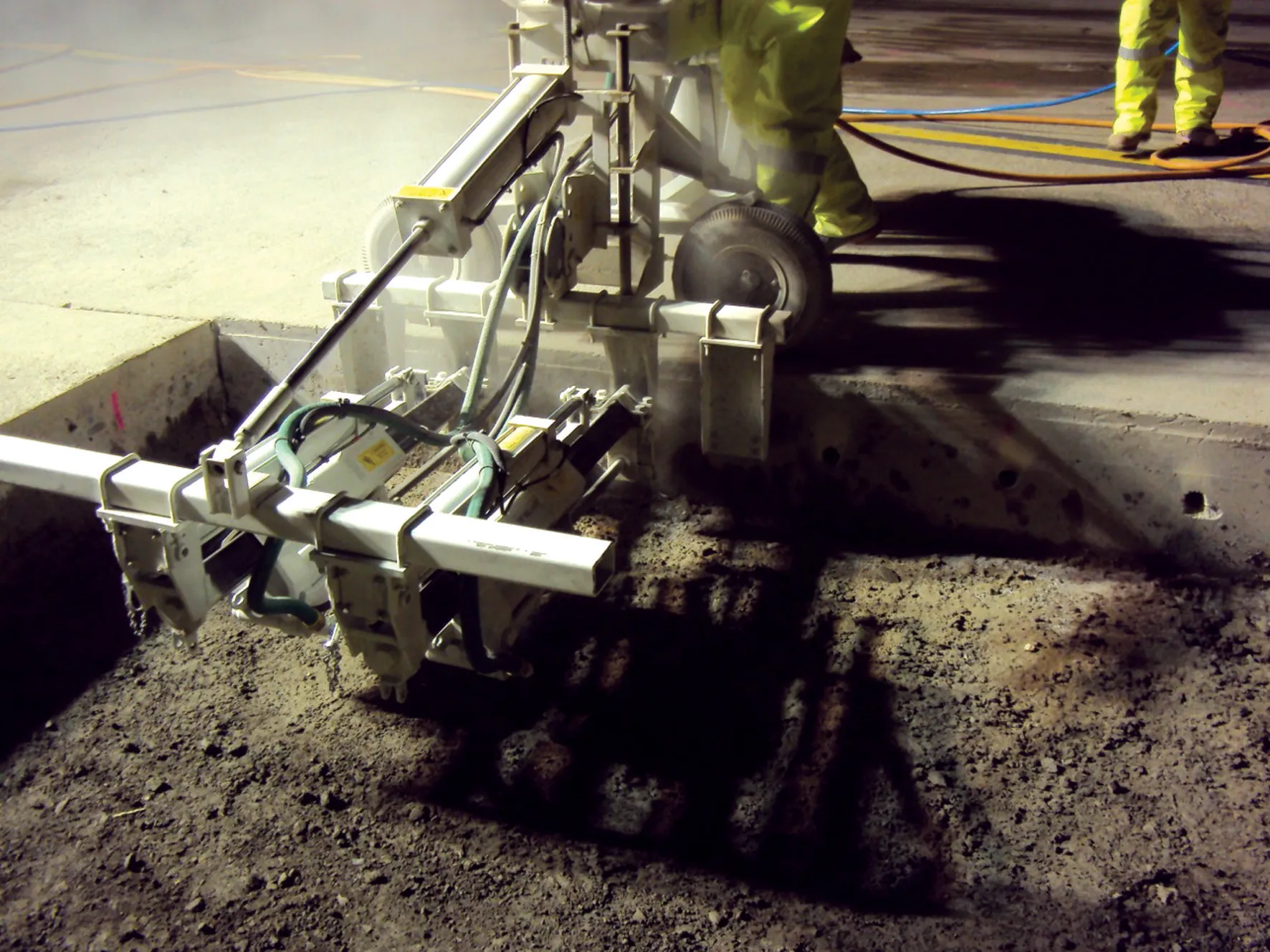

Performance and productivity have been crucial for the project, given the tight time constraints that have seen the units operating 24 hours/day for extended periods. The machines have been supplied by the Maren-CMO, New Holland Construction dealership based in Curno, near Bergamo, to the contractors Vitali and Artifoni. These well-known Italian contractors form part of the consortium that has been carrying out the runway resurfacing work.

Vitali has already refurbished the runways at Milano Malpensa and Cuneo Levaldigi airports and has carried out an array of operations at Orio al Serio. These works have included breaking up the old runway, replacing the runway lighting, cabling and water drainage system, paving of the new runway and installing its markings.

To maximise productivity, accuracy and uptime the contractor has used the New Holland equipment fitted with sophisticated machine control technologies, as well as the firm’s advanced telematics systems.

Meanwhile Artifoni is a specialised company that carries out large-scale wastewater and drainage systems, hydraulic works, and surface paving. The company is a long-standing customer for New Holland Construction with a fleet of 27 units from this supplier. For this airport project, Artifoni has handled the civil works for the new runway, including hydraulic works and cable duct installations. The company also carried out excavation and demolition operations, as well as preparing the new runway’s sub-base.

The New Holland excavators working at the Orio al Serio airport were supplied by Maren-CMO, fully equipped units with equipment including hydraulic hammers and circuits for grabs and bucket crushers.