HD Hyundai Construction Equipment is now moving up the size class with its latest offerings for the crawler excavator and wheeled loader segments. The firm’s new HX800A L and HX1000A L excavators and HL985A wheeled loader are now top-of-the-range models for the company.

The HX800A L is an 80tonne class excavator and the HX1000A L is a 100tonne machine, while the new HL985A loader weighs in at 35tonnes and is designed to work with a 7m3 bucket. All three models benefit from high comfort cabs with low noise and good all-round vision as well as meeting Stage V/Tier 4 Final emissions compliance.

The HX800A L and HX1000A L suit use in bulk earthmoving and infrastructure projects. The HX800A L uses the six-cylinder Perkins 2506J, providing 400kW at 1,800rpm and 2,468Nm of torque at 1,400rpm. The larger HX1000A L is powered by the Perkins 2806J, offering 460kW at 2,000rpm and 2,952Nm at 1,300rpm.

An electronic hydraulic power control minimises fuel consumption, while increasing digging efficiency. It has nine sensors across the machine to calculate the required flow and pump output, optimising efficiency. The excavators have four operating modes and four power modes, working in combination with Variable Speed Control and Pump Torque Control, allowing the operator to select engine and hydraulic outputs to suit the task. A boom priority mode and swing priority mode increase breakout power or slewing speed to suit the operation.

The HX800A L is suitable for 4.25-5.24m3 buckets and the larger 100tonne machine will be able to work with 5.4-6.8m3 buckets. The two machines are offered with a choice of short mass excavation and longer monobooms, and with the option of two dipper arm lengths.

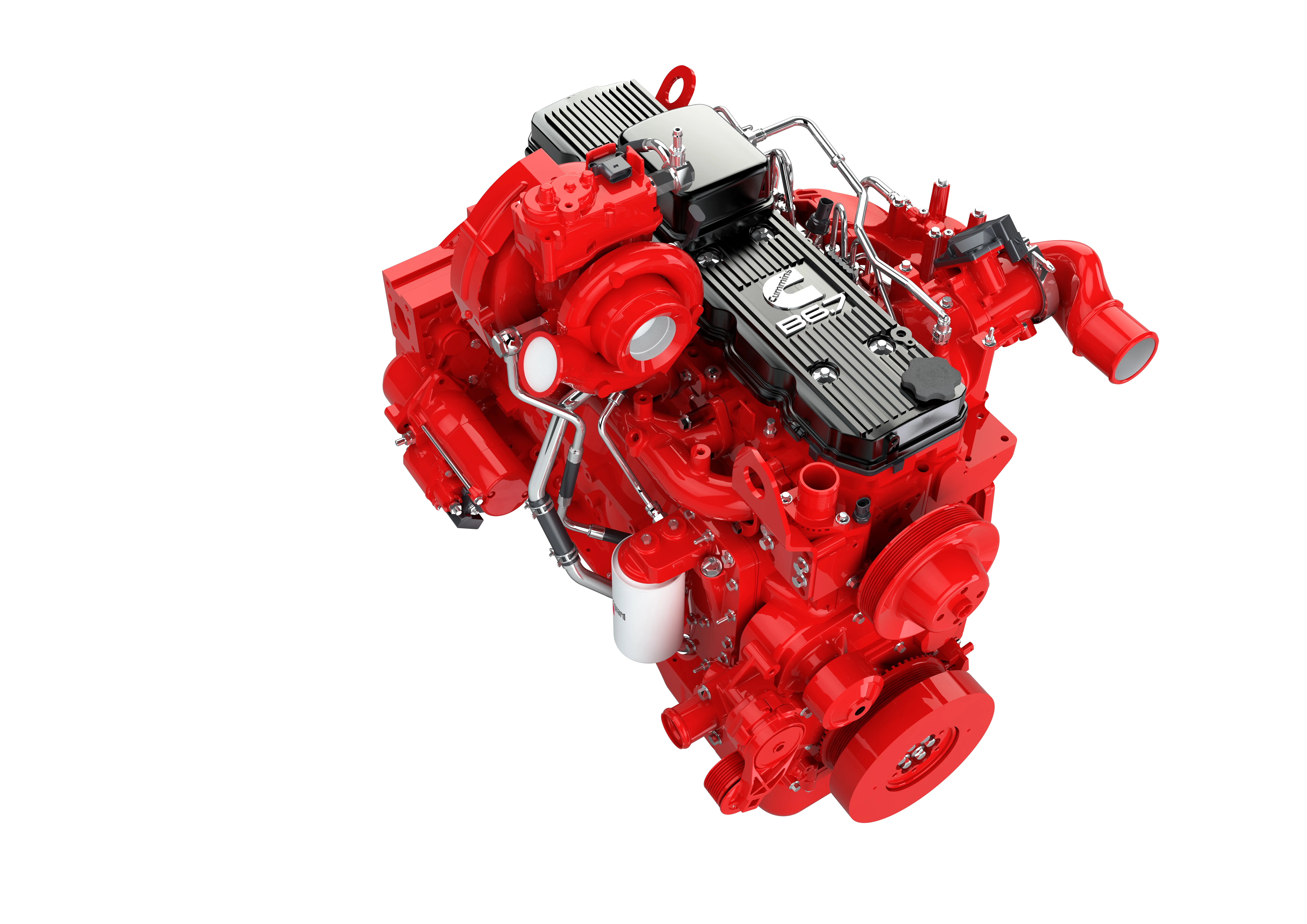

The HL985A loader shares the robust design of the smaller A-Series machines and is powered by the latest Cummins X12 diesel engine, delivering 321kW at 2,100rpm and 2,300Nm of torque at 1,400rpm. That is 10% more power and 20% higher torque than before, with lower fuel consumption and exhaust emissions. The HL985A can be fitted with a 6.5m3 or 7.0m3 bucket, with or without teeth and cutting edges.

The loader benefits from an Eco gauge in the cab monitoring fuel consumption in real-time. A Smart Power mode reduces fuel use, adjusting engine speed while loading the bucket. Driving through a five-speed transmission with lock-up clutch, the machine offers a maximum travel speed of 40km/h. The transmission has an Intelligent Clutch Cut Off (ICCO), minimising power loss in the torque converter and preventing excessive power during braking. A hydraulically-locking differential in the front axle ensures traction when digging and loading.