Karin Junker, Regional Sales Manager Eastern Europe and Russia, HAENNI Wheel Load Scales, Switzerland, looks at weight enforcement in Croatia Croatia's modern period in history began in 1990 with the country's change of political and economic system, and the achieving of independence from Yugoslavia on 25 June, 1991. The country remained war torn during the 1990s but regained stability and economic growth after the turn of the millennium.

During a recent trip to Croatia to visit HAENNI's distributor in t

July 19, 2012

Read time: 4 mins

Karin Junker, Regional Sales Manager Eastern Europe and Russia, HAENNI Wheel Load Scales, Switzerland, looks at weight enforcement in Croatia

Croatia's modern period in history began in 1990 with the country's change of political and economic system, and the achieving of independence from Yugoslavia on 25 June, 1991.The country remained war torn during the 1990s but regained stability and economic growth after the turn of the millennium.

During a recent trip to Croatia to visit HAENNI's distributor in the Balkans, VAGE of Zagreb, I had the opportunity to visit the end-user of our portable static wheel load scales,

Hrvatske Ceste (Croatian Roads). During an interview with the head of the department, Mr. Ljubo Roso, and while participating at a live weight check near Zagreb [the Croatian capital] on the highway leading to the coastal town of Rijeka, I learned a lot about weight enforcement in Croatia.

Croatia (then still integrated in former Yugoslavia) started to carry out weight enforcement in about 1990. Among other brands they use%$Linker:

Since then Hrvatske Ceste has bought the electronic static wheel load scale WL 103 in the standard form and as an XL version on a regular basis to equip its seven weighing teams. There are six teams (each of two persons) responsible for about 3,000-5,000km of road and a seventh team is supervising and travelling all over the country. Approximately 1,050km of motorway spans the country, and a further 400km are planned to be built. There are 6,800km of National Roads for which Hrvatske Ceste is responsible for planning, building and maintenance. However, responsibility for the weight enforcement goes for all roads across the country. In addition there are roughly another 20,000km of so-called local roads.

Weight checks are carried out daily and can occur at any time of the day or night at any of the 850 designated weighing sites in the country. Besides weighing with portable static wheel load scales, Hrvatske Ceste operates weigh bridges, especially at border points, to monitor through traffic.

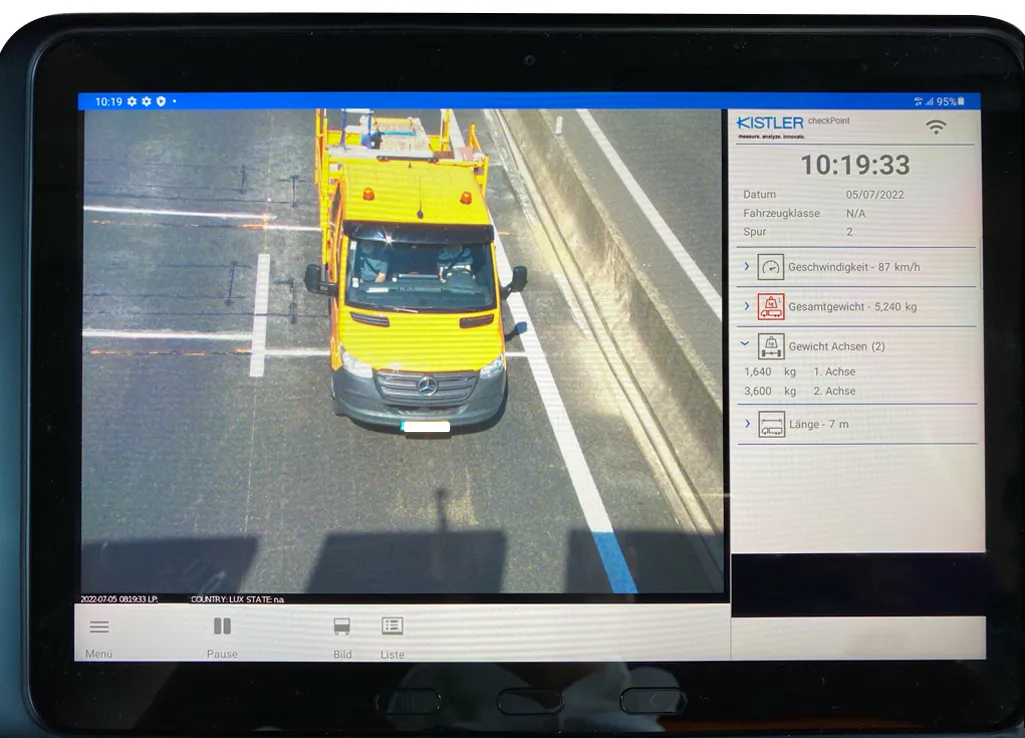

For pre-selection, statistical purposes and road studies, bridge weigh-in-motion (WIM) equipment is installed throughout the country on the superstructure of existing bridges. Last year a WIM station was installed near Zagreb with more installations to follow in the near future.

When carrying out weight checks Hrvatske Ceste needs the assistance of the Traffic Police, who are responsible for stopping vehicles to be weighed and carrying out all necessary checks such as resting time and cargo documents. The actual weight checks are performed by Hrvatske Ceste.

Roughly 12,000 suspicious looking vehicles are weighed during the course of one year, and almost 30% (3,500) are overloaded. By law there is a total weight limit of 40tonnes, 10tonnes on the axle (11.5tonnes on the driving axle).

According to the purpose of the weighing, they choose the appropriate configuration of scales. Their preferred way of weighing is to use six (standard) scales to weigh a three-axle vehicle at once or to at least weigh an axle group in one operation. To measure a large number of vehicles in a short time, two scales (standard or XL) are used for easy axle-by-axle-weighing. The latter layout includes levelling mats, usually four large ones (two in front and two behind the scales) plus a long distance display so that the driver can read the weight. In both cases the scales are usually connected to a laptop computer in a van parked nearby so that a ticket print-out can be made on the spot, and the measuring results can be stored and later further processed back at the office. Both operations see the vehicle stopped and the scales placed in close proximity to the wheels. The vehicle is driven onto the scales. When weighing axle-by-axle the vehicle is driven onto the scales consecutively, until all wheels have been measured. A 3% deduction is applied to all weighing results for compensating all unfavourable effects on the axle loads caused by friction in the suspension and level differences of the weighing site.

Weight enforcement in the neighbouring states is done in the same or a similar way as in Croatia, with the exception of Slovenia where a private company does it with the assistance of the police.