With Smart Doc, Hamm is going down new digital paths and offering a handy means of compaction documentation. In brief, Smart Doc is "self-monitoring for everyone". "We pursue two key aims with the app. Firstly, we offer customers who deal with earthwork sites only occasionally a tool with which they can create proof of compaction very easily. Secondly, we support inexperienced roller operators in their daily work with Smart Doc. They often do not have the practical experience of their colleagues, but are familiar with the digital world. The live display on the smartphone visually demonstrates how compaction develops during the current transit. Consequently, high-quality and homogeneous compaction can also be achieved by young roller operators. So they become more experienced in a fun way," explains Dr. Axel Mühlhausen, Product Manager Digital Solutions at Hamm AG.

Available for H series and H CompactLine series

With Smart Doc, every roller operator of a compactor from the H series or the H CompactLine series can produce a report about compaction. As a prerequisite, the compactors must be equipped with the Hamm Compaction Meter, which many customers are already using anyway. There is also a Bluetooth® interface. This is available as an option for the corresponding model. The compactors of the H CompactLine series should also be equipped with a speedometer and a vibration frequency display. As soon as the app connects the mobile phone with the CAN bus of the roller via Bluetooth®, the current compaction parameters (speed, frequency, amplitude and compaction value) are transmitted to the app. Consequently, the Bluetooth® Low Energy standard ensures extremely energy-efficient data transfer. Should the battery of the mobile phone nevertheless be drained, it can be charged via the 12 V socket or the optional USB charging port on the driver's platform.

Economical alternative to complex continuous compaction control systems in earthworks

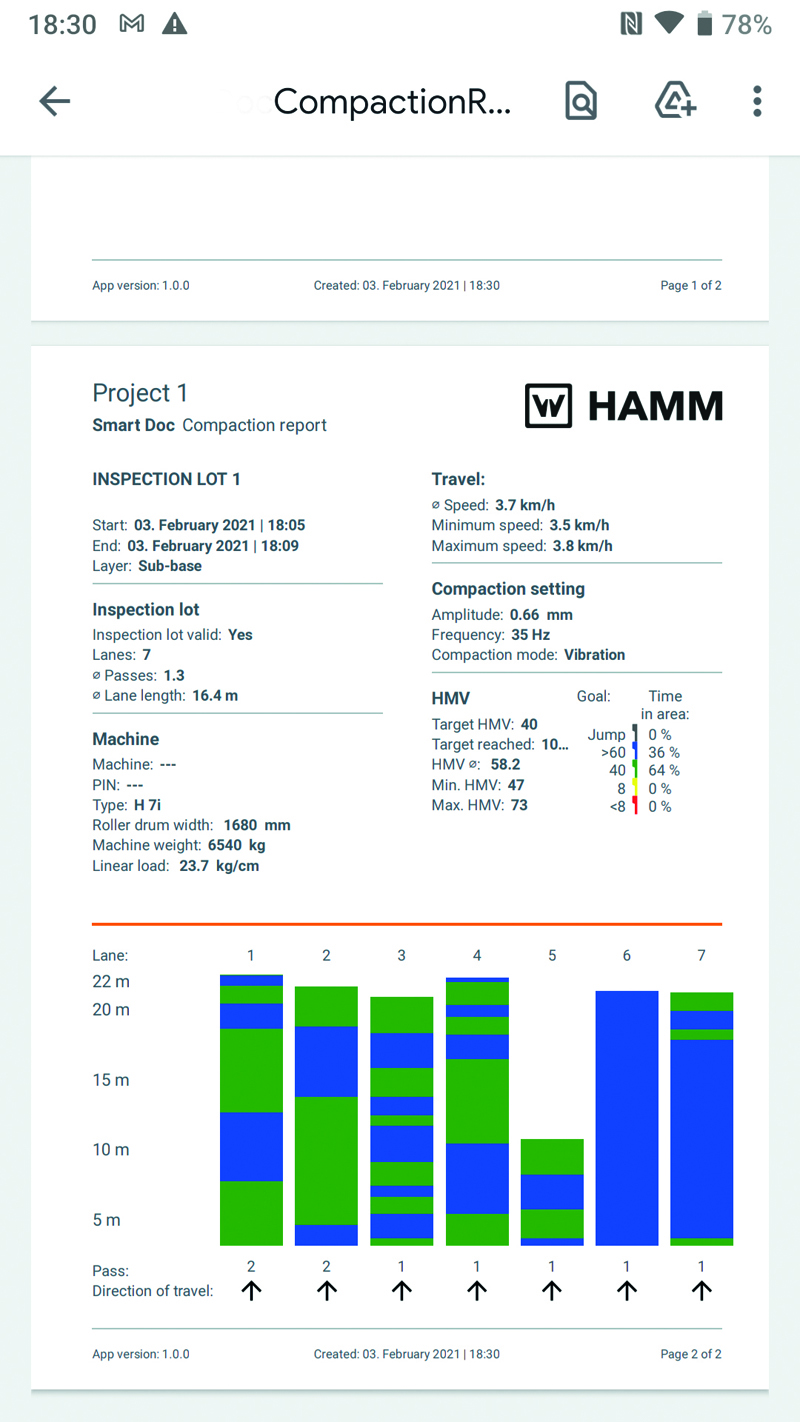

The result delivered by the app is a compaction report in PDF format. This shows the essential data on the project and contract section, the technical data of the compactor (weight, drum width and static linear load), the various compaction parameters and the number of transits per compaction lane. The report also contains a graphic that illustrates in which places and how intensively compaction has already taken place.

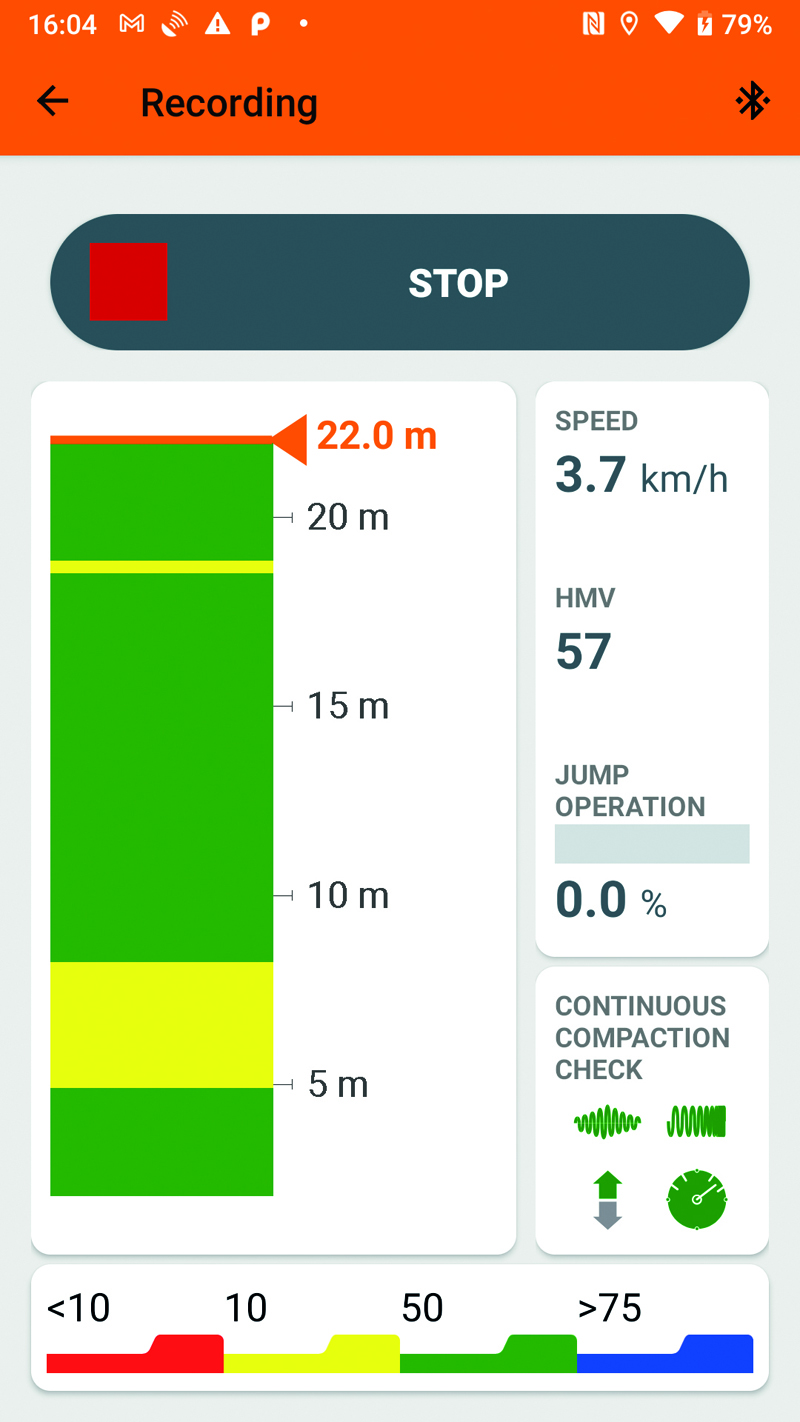

Smart Doc records data as soon as vibration or oscillation is used during compaction. In order to do so, the load-bearing capacity of the ground is determined by means of an acceleration sensor on the drum during dynamic compaction. The HMV (= Hamm Measurement Value) is used as a measured variable for compaction – a measure of the load-bearing capacity of the substrate during compaction. With real-time visualisation of the compaction data and the option to generate and show a compaction report at any time, Smart Doc fulfils the basic requirements of a continuous compaction control system. In short – with Smart Doc, Hamm offers an economical alternative for achieving high-quality compaction at earthwork sites with the required basic continuous compaction control in a way that can be verified.

Easy operation

Just like the Hamm compactors themselves, the app is also very easy to operate. Once the project data has been entered, the recording can be started and stopped automatically when switching on or off the vibration or oscillation. In addition, every transit and every new track can be individually documented and automatically saved. Once work has finished, the data export is triggered by a tap of the finger. During compaction with vibration or oscillation, the operator can follow the current status live on the smartphone. This representation is highly appropriate for training new personnel, as inexperienced operators can square their perception with the actual compaction result with Smart Doc.

Free

The app is free and can be installed via the Google Play Store on all Android smartphones and tablets from Android 6.0. The app is available in German, English, Spanish and French.

Sponsored content produced in association with WIRTGEN GROUP