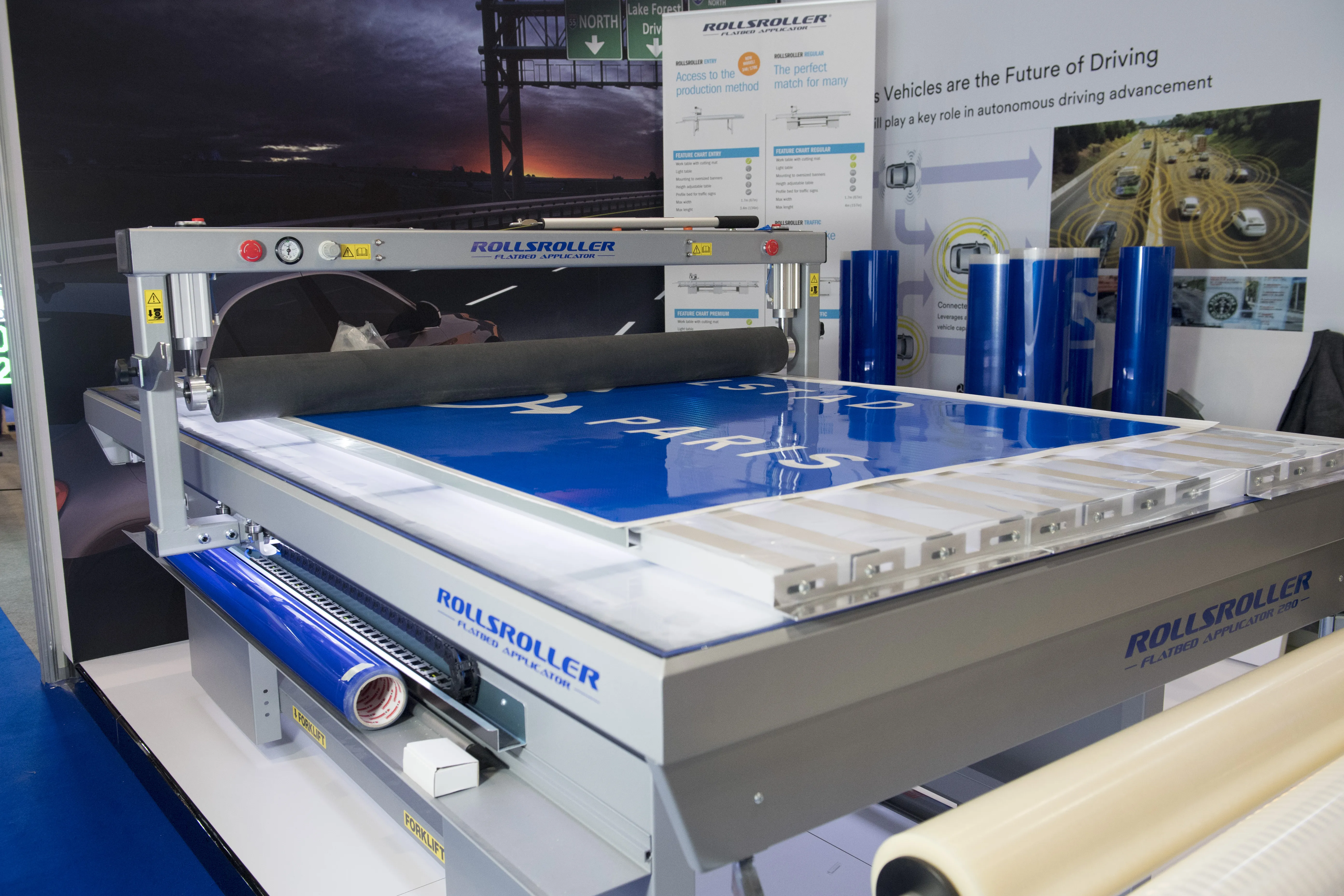

It has a special profile bed adjustable to fit almost any extruded guide sign panels, according to the manufacturer. Bed length for the Rollsroller Traffic 600/145T model is 6,000mm and width is 1,450mm. The pneumatically controlled roller is automatically adjusted for substrates up to 60mm. The adjustable aluminium profile bed is designed specifically for mounting a high volume of guide sign panels.

There is also a roll holder on a glide beam for pre-masking tape and laminate. A stop static kit (cord and magnet) will dissipate static electricity. The Traffic model is most often used in combination with one of Rollsroller’s other units - an entry, regular or premium model - to create a complete workflow. The latest entry model is the Rollsroller 340/170E which has a bed length of 3,400mm and width of 1,700mm.

The applicators are manufactured from start to finish at the company’s factory in Karlstad, Sweden, to ensure quality control, according to Rollsroller. The chassis and beam are made completely out of steel because it does not deform over time, even if the underlying surface is uneven.

In March, Rollsroller will demonstrate its applicators at