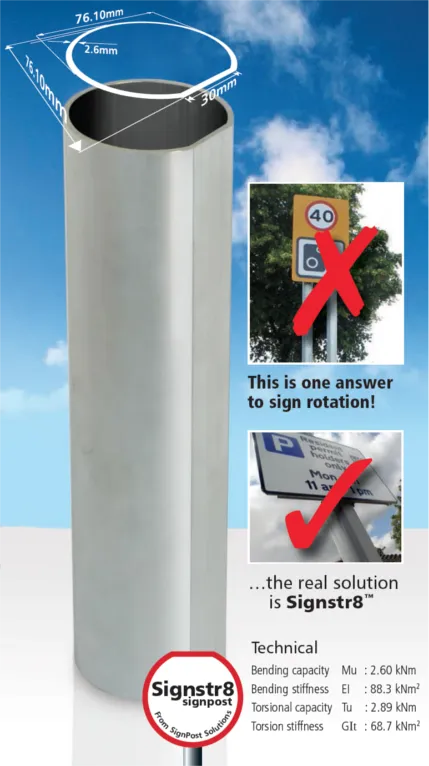

Gateshead has specified Signstr8 for all of its steel post sign installations where strength capacity allows. As opposed to standard round poles, the 76mm diameter steel Signstr8 pole has a 30mm flat face to prevent the sign from being misaligned or rotated.

The design avoids the need for costly call-outs to ensure signs are correctly orientated. They can prevent unnecessary and costly disputes as the signs are always facing the right way.

Trevor Waggett, engineering manager at Gateshead Council, said that his team had previously purchased tubular and square poles for different applications. “With Signstr8, however, multiple applications can be accommodated which simplifies and streamlines the procurement process, reduces order times and prevents stocking issues.”

The patented Signstr8 anti-rotational sign post accepts standard clips, base plates and external caps. It complies with passive safety standards because the moment capacity is significantly lower than that of a standard 89mm x 3.2mm S355 grade steel post, according to the manufacturer.

Designed to BS EN 12899 and precision rolled to EN 10305-3, the posts are available as galvanised (to ISO 1461), PVC coated (grey or black), painted and more recently in aluminium 76mm and 89mm diameters.