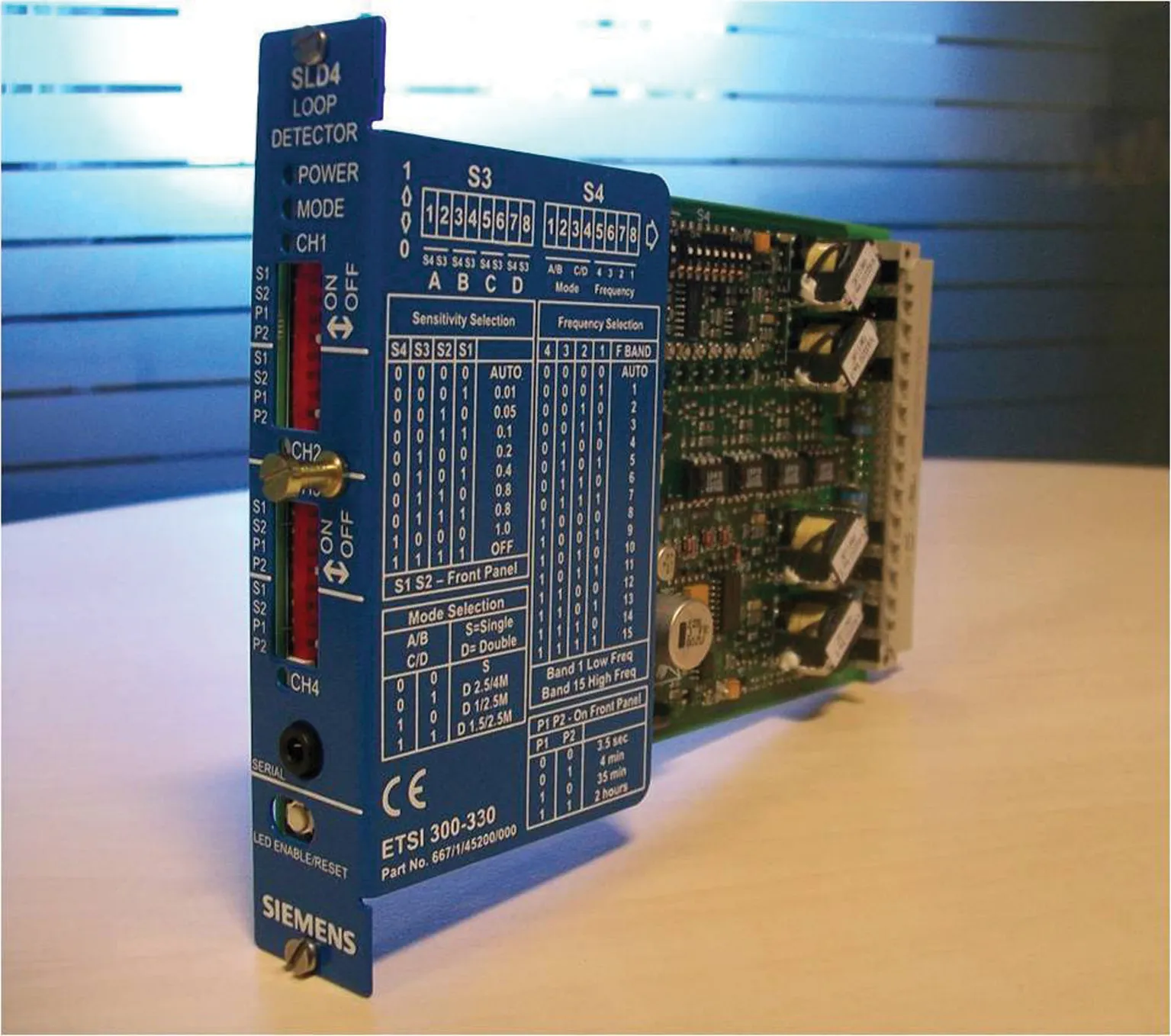

An improved version of the SLD4 loop detector family is now available from Siemens. The upgraded SLD4 is said to include sophisticated length-based classification with configurable outputs, which can be set to activate when specific conditions are detected, such as large vehicles exceeding a predefined speed. As well as offering standard vehicle detection, the latest version of the SLD4 ca

November 11, 2013

Read time: 2 mins

An improved version of the SLD4 loop detector family is now available from 1134 Siemens.

The upgraded SLD4 is said to include sophisticated length-based classification with configurable outputs, which can be set to activate when specific conditions are detected, such as large vehicles exceeding a predefined speed.

As well as offering standard vehicle detection, the latest version of the SLD4 can also be used in specialised bus, tram and Light Rail Transport (LRT) schemes and other similar applications requiring excellent detection accuracy.

Designed for maximum reliability and using the latest inductive loop detection algorithms, the SLD4 detector family complements the company’s full range of detection options. These include Selective Vehicle Detection and above-ground detection of vehicles and pedestrians.

According to Keith Manston,2768 Siemens Mobility, Traffic Solutions head of product management, the enhanced SLD4 still delivers the self-tuning and fully automatic set-up features of the existing SLD4, ensuring optimum and reliable performance without interference. This is said to represent a significant advantage over manual setting of frequency and sensitivity parameters which can often be a challenge, with failure to achieve this correctly causing detectors to ‘chatter’ or otherwise fail to operate.

SLD4 detectors are fully compliant with UK specification TR2512 and provide four separate detection channels with full solid-state outputs for maximum reliability. For challenging or special applications, a PC support tool enables many aspects of the detectors’ functions to be accessed for specific deployment scenarios.

The detectors may also be powered from either AC or DC supplies. Low power requirements, with operation possible at voltages as low as 10V DC, makes support within battery powered equipment a viable option where needed.

The upgraded SLD4 is said to include sophisticated length-based classification with configurable outputs, which can be set to activate when specific conditions are detected, such as large vehicles exceeding a predefined speed.

As well as offering standard vehicle detection, the latest version of the SLD4 can also be used in specialised bus, tram and Light Rail Transport (LRT) schemes and other similar applications requiring excellent detection accuracy.

Designed for maximum reliability and using the latest inductive loop detection algorithms, the SLD4 detector family complements the company’s full range of detection options. These include Selective Vehicle Detection and above-ground detection of vehicles and pedestrians.

According to Keith Manston,

SLD4 detectors are fully compliant with UK specification TR2512 and provide four separate detection channels with full solid-state outputs for maximum reliability. For challenging or special applications, a PC support tool enables many aspects of the detectors’ functions to be accessed for specific deployment scenarios.

The detectors may also be powered from either AC or DC supplies. Low power requirements, with operation possible at voltages as low as 10V DC, makes support within battery powered equipment a viable option where needed.