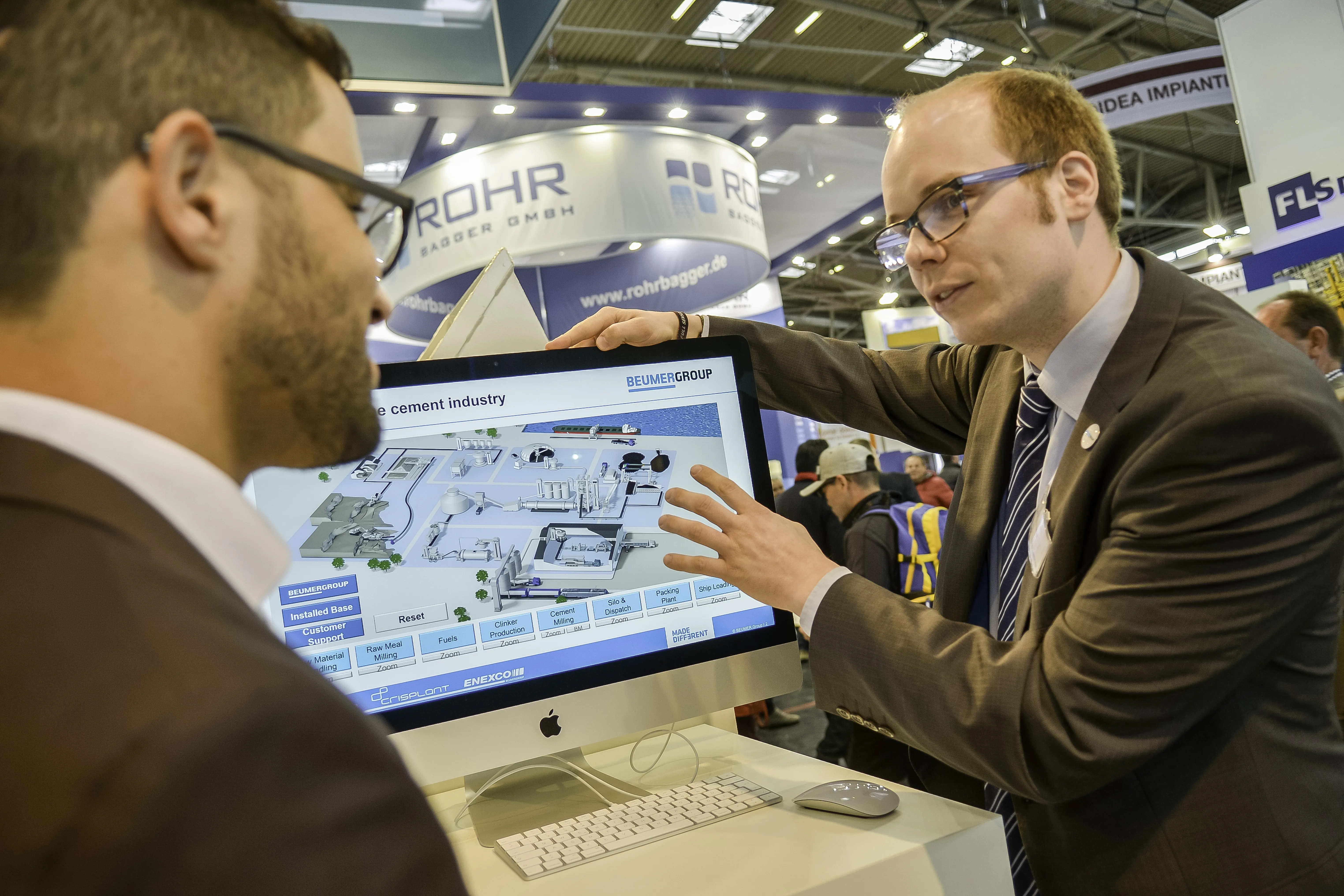

The BEUMER Group claims that its new materials handling system can generate cost savings for cement plants. The Autopac 3000 system allows the simultaneous loading and palletising of bagged materials such as cement, lime and gypsum. The firm says that this new handling system can replace time-consuming and potentially inaccurate hand bagging operations.

Accuracy is optimised by the conveyor, which delivers the bags and provides a second quality control check. The bags are weighed automatically by the sys

July 5, 2016

Read time: 1 min

The 7303 BEUMER Group claims that its new materials handling system can generate cost savings for cement plants. The Autopac 3000 system allows the simultaneous loading and palletising of bagged materials such as cement, lime and gypsum. The firm says that this new handling system can replace time-consuming and potentially inaccurate hand bagging operations.

Accuracy is optimised by the conveyor, which delivers the bags and provides a second quality control check. The bags are weighed automatically by the system, which then returns any showing the incorrect weight for reprocessing. The filled bags are then supplied to the truck and are automatically loaded, with the Autopac system offering a loading capacity of 3,000 bags/hour.

The process also offers benefits for the truck drivers, who park their vehicles in a designated spot and can then use a display to initiate the loading operation.

Accuracy is optimised by the conveyor, which delivers the bags and provides a second quality control check. The bags are weighed automatically by the system, which then returns any showing the incorrect weight for reprocessing. The filled bags are then supplied to the truck and are automatically loaded, with the Autopac system offering a loading capacity of 3,000 bags/hour.

The process also offers benefits for the truck drivers, who park their vehicles in a designated spot and can then use a display to initiate the loading operation.