Luxembourg has opted for Kistler’s KiTraffic Plus weigh-in-motion system as it implements new commercial vehicle enforcement to meet the European Union requirements.

The WIM installation is located on the A6 motorway about 2km from the border with Belgium. Several hundred meters of the road surface were renewed ahead of time so there would be no need to replace the sensors after a few years because of scheduled maintenance. The complete KiTraffic Plus system weighs trucks and delivery vans without interrupting motorway traffic, providing the basis for efficient weight enforcement.

Operating since last summer, it has proven highly reliable, according to the manufacturer. It has been enabling efficient preselection, automated weight detection of overloaded vehicles at high speeds and supports handling of the entire process.

Weigh-in-motion by Kistler has automatic weight measurement during travel plus optical vehicle detection and recording ensure efficient preselection of trucks and vans. These are then weighed statically again and checked for other violations- tyres, dimensions, validity of documentation and more.

Several reasons prompted the administration to opt for KiTraffic Plus. First and foremost, this system is certified to OIML-R134. It is capable of reliably measuring commercial vehicles moving at high speeds - trucks at 90km/h and vans at 130km/h. The Luxembourg system achieves accuracy of 5% of the vehicle's total weight. It does this with the help of two rows of Kistler Lineas WiM sensors and induction loops installed in the road surface on each of two traffic lanes.

Last but not least, KiTraffic Plus features a flexible modular system: a complete measuring chain – from sensor through to software – that can be tailored to a customer’s requirements by adding components such as dimension scanners, numberplate recognition (ANPR) and tyre detection.

Another benefit is the statistical data acquired by the WiM system can optimise the timing of commercial vehicle enforcement and calculate the remaining useful lifetimes of roads and bridges.

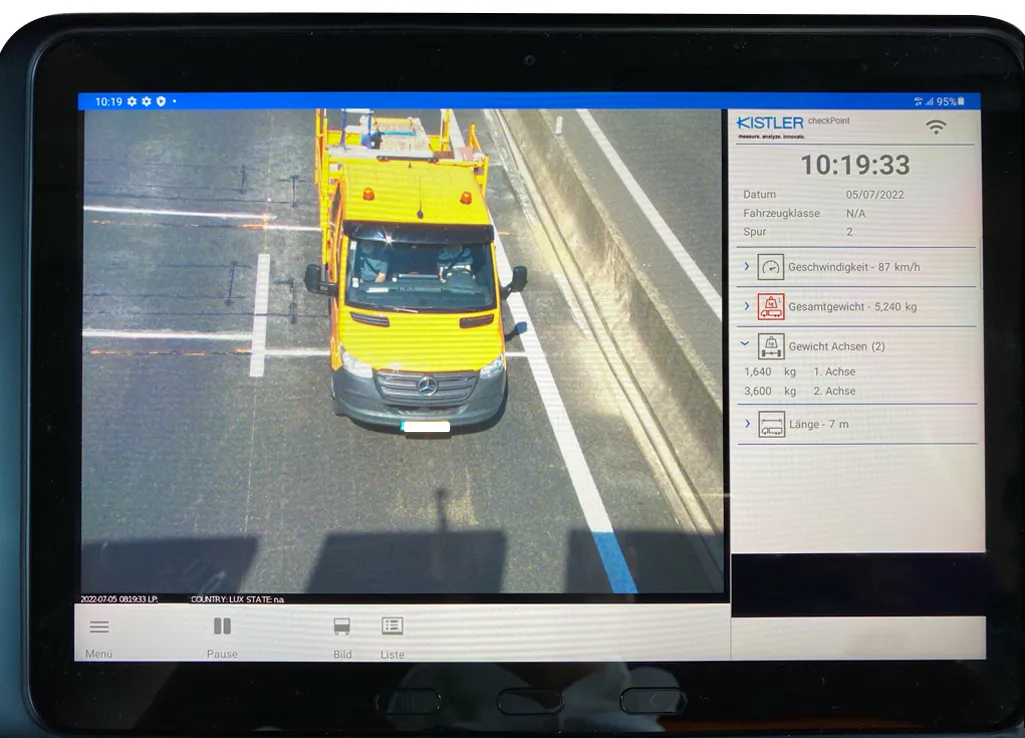

Alongside the WIM sensors, the Luxembourg solution uses overview cameras. The images they capture make it easy for the inspecting officers to identify vehicles intended for preselection. These features, combined with high-accuracy weighing in moving traffic, result in highly efficient enforcement: the police enforcement squad can see overweight and other violations directly on their tablets. Officers can then initiate the pursuit – leading to high success rates at the checkpoint.

The WiM electronic equipment, including the Data Logger, can be delivered prewired and preconfigured upon request and is accommodated in a control cabinet near the sensor installation. The police tablets connected to the WiM system run Kistler's Checkpoint software which displays all information on the detected vehicle at a glance.