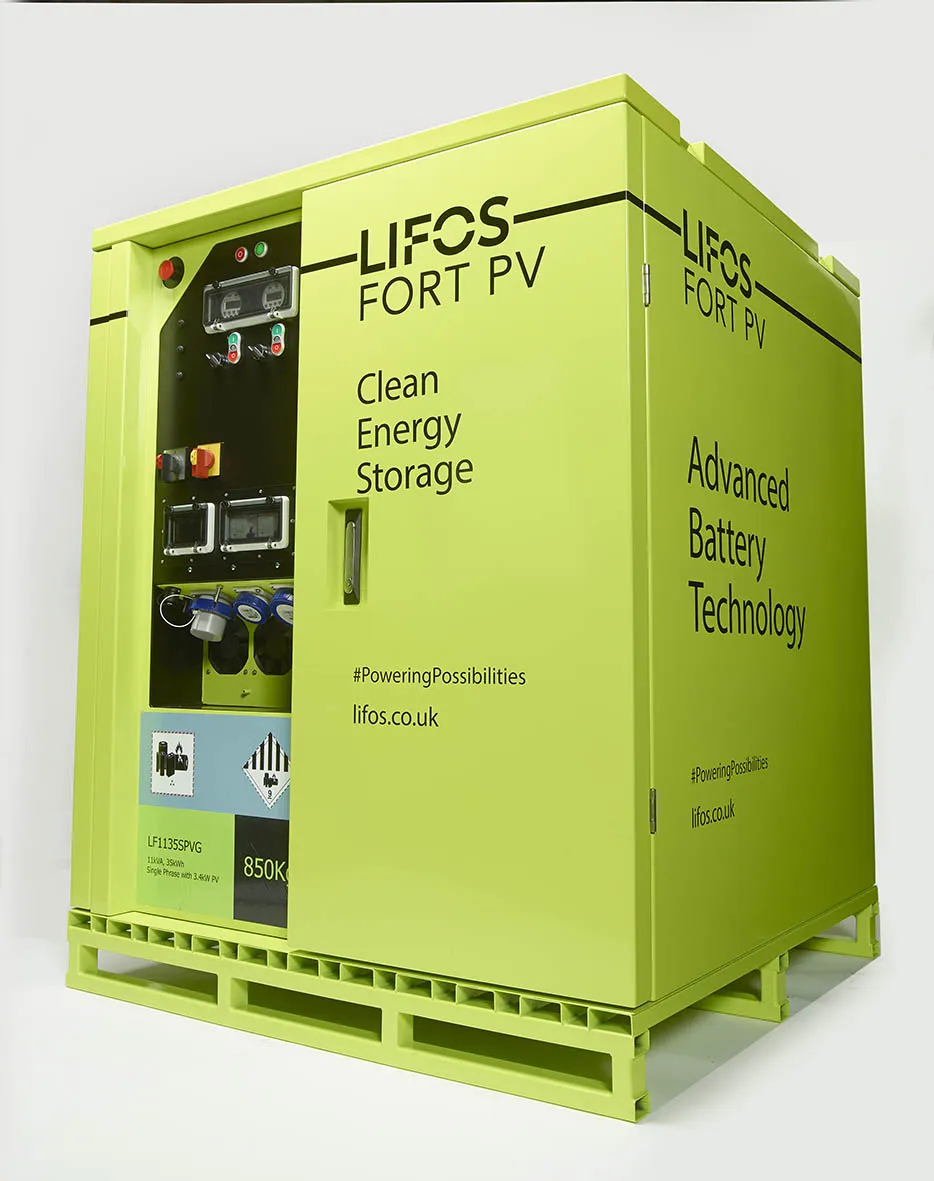

LIFOS says that its new all-in-one Fort solar photo-voltaic battery storage system helps the hire and construction industries transition to a diesel-free and low-carbon future.

The hybrid and renewable energy system comes in three models - 12kWh, 23kWh and 35kWh, with further options slated for introduction later this year.

The Fort has 18 solar panels delivering 3.4kW of green power that can be quickly deployed either by using the fitted solar panel kick stand or the optional container roof mounting kit. The kit makes it ideal for use on site and it can be fixed onto the roof of a welfare unit. The unique design allows for easy transportation and use on all sites.

LIFOS Fort batteries use A grade lithium iron phosphate battery cells, renowned for their stability, longevity, reliability and complete traceability.

The Fort comes with a five-year warranty but all Fort customers have the option to join the LIFOS Seven-Year-Switch programme, explains Adrian Williams, founder and chief executive of LIFO. This allows customers at the end of year seven to upgrade critical components so the battery is operating like new, extending the life expectancy of the asset to 15 years and beyond. An outstanding return on investment all backed up by the LIFOS Tech Support Team.

In addition, LIFOS has designed the LiQ Battery Management software to remotely control, monitor and report data from the Fort. It will provide information on diesel usage, CO2 savings and solar power generation for easier ESG reporting.

LIFOS Advanced Battery Technology, based in Telford, England, designs and manufactures a range of advanced solar battery storage systems. Williams has been designing batteries and storage solutions since 2005 for a variety of applications, including off-grid energy requirements, the marine and caravan industry and domestic energy storage for homes and small businesses.