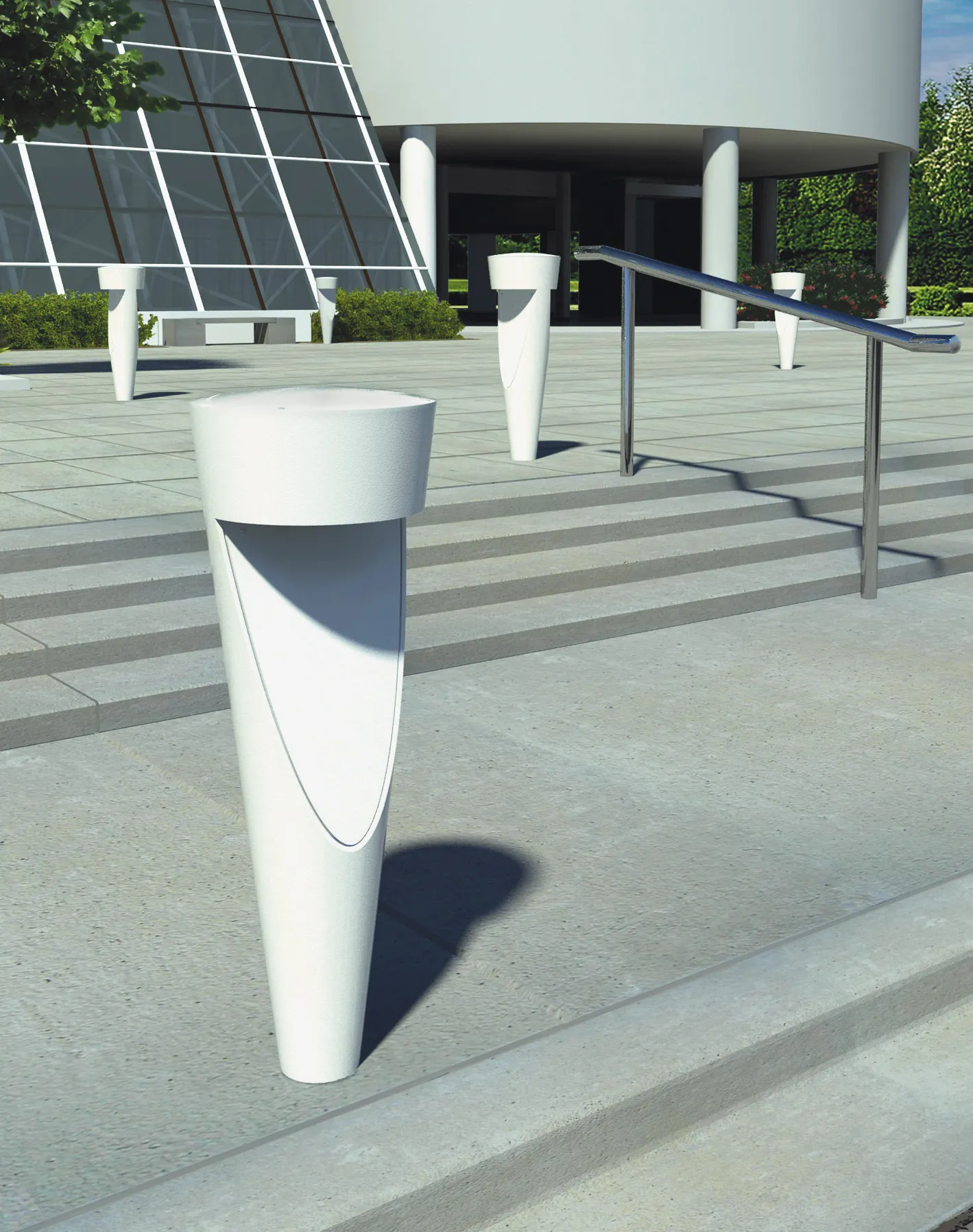

Efficient and effective lighting is possible using the new Tornado bollard from US Architectural Lighting. This unit is said to offer a modern approach to public area lighting, along with significant energy-savings, while featuring a micro-prism lens, the unit produces a soft lighting effect.

February 13, 2012

Read time: 1 min

Efficient and effective lighting is possible using the new Tornado bollard from 1092 US Architectural Lighting. This unit is said to offer a modern approach to public area lighting, along with significant energy-savings, while featuring a micro-prism lens, the unit produces a soft lighting effect. Available in two models, the TNA with asymmetric light distribution and the TNS with a symmetric light pattern, the Tornado's novel inverted shape provides glare-free illumination to boost pedestrian safety. The asymmetric Model TNA is designed for pathways, kerbs and driveways where perimeter lighting is required. The symmetric Model TNS is designed for use in open areas where illumination is required on all sides of the bollard. Both models can be installed at the same project. Either model can be specified in metal halide (39 to 100W); HPS (50 to 100W); CFL (26 to 42W); and a new LED system. The housing is made from durable corrosion-resistant low copper cast aluminium alloy with a 6.35mm minimum wall thickness. The bollard features an electrostatically-applied polyester powder-coat finish baked at high temperatures for maximum hardness and durability.