Edeva, the Swedish manufacturer of Actibump, have, after 10 years and 100 installations in the Nordics and Australia, has made the system available worldwide.

The first Actibump was installed in Linköping, Sweden, in 2010 and there are now around 100 Actibump units installed in Sweden, Australia, Norway and Iceland. It has both been installed on sites in the Swedish capital Stockholm, as well as in smaller villages in the road network of the Swedish Transport Administration.

Actibump is also installed in all nine lanes at the toll station on the Øresund bridge in the direction from Sweden to Denmark. Seven units are installed at the Bentley campus of Curtin University in Perth, Western Australia. There are several installations in the planning phase in a number of European countries, in Denmark and France, for example, as well as in other parts of the world.

As part of the official launch for global availability, Edeva presented Actibump to visitors to its stand at the recent Intertraffic exhibition in Amsterdam.

Edeva demonstrated the system which, the company says, solves the compromise between accessibility and traffic safety. The SmartCity system consists of the active speed bump, Actibump and a software platform called EdevaLive that monitors the hardware and collects and presents data from sensors on site.

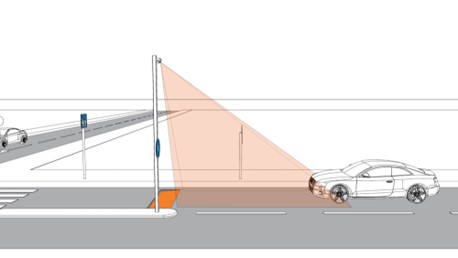

The visible part of the Actibump is a hatch integrated into the road surface. A radar measures the speed of oncoming vehicles and when a speeding vehicle approaches, the hatch lowers a few centimetres into the road surface, creating an indentaion that gives the driver a physical reminder of the speed limit.

Edeva says that it leads to a behavioural change where drivers stop speeding to avoid the inverted speed bump. For all drivers abiding by the speed limit the hatch remains level with the road surface and doesn’t affect the vehicle. This means that buses and emergency vehicles get better accessibility compared to regular speed bumps, bus drivers and passengers get a comfortable ride and vulnerable road users get a safe passage.

EdevaLive collects and displays data from the radar regarding speeding, average speed, 85th-percentile speed and speed distribution in a web interface. Edeva says that the data makes it easy to follow up the effects of the system and has proven that the Actibump has an impressive effect on speeding behaviour that lasts, or even improves, over time. The result from the current installations is that the 85th-percentile speed ends up at the speed limit ±4 km/h between six months and a year - regardless of previous speeding behaviour.

Speed limit and other variables are set through the web-based interface of the software platform EdevaLive that also monitors all hardware connected to it and presents the data collected by the Actibump and other sensors. Each customer has access to data regarding speeding and traffic flow from their own Actibumps.

Additional sensors can be installed in the Actibump or at the Actibump installation site in to get data regarding vehicle types, vehicle weight, noise levels, air quality, temperature and ground vibrations. Other sensors can be added upon request. The system has optimal function at speed limits of 50 km/h and lower.

With more than 200,000,000 vehicle-passages over all the installed Actibumps, the system has proven its robustness. Edeva says that independent evaluations have shown the system to decrease noise, improve traffic flow and yielding behaviour and decrease the speed to that of the set speed limit ±4 km/h, regardless of speed limit or previous speeding behaviour.

Edeva is ISO certified in quality and environment, ISO 9001 and ISO 14001.