Aximum Produit Èlectroniques’ (APE) development of its new 45 highway barrier stems from what the French firm says is a search for better productivity through shorter toll lane occupancy, a reduction in ownership costs and reduced risks for toll employees during maintenance operations.

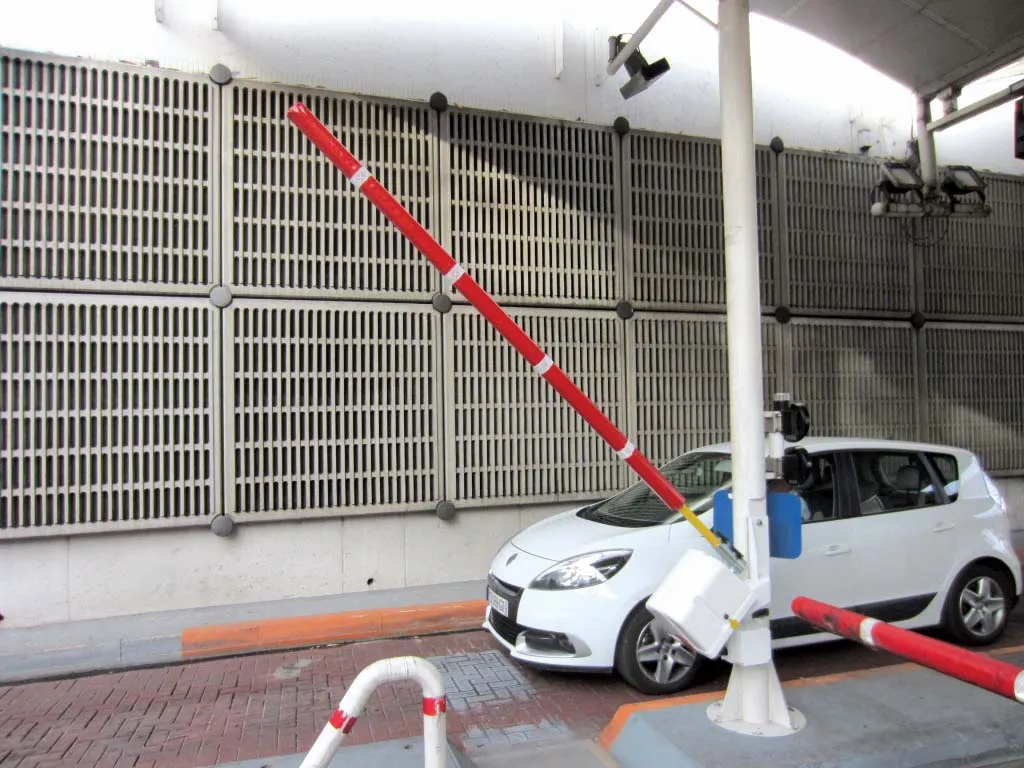

Of the barrier’s name Frédéric Lardeur, APE’s marketing and communications director, said, “45° is the angle made when the barrier boom moves to open the toll lane. When a barrier opens, the boom traditionally makes a 90°

April 3, 2014

Read time: 3 mins

Of the barrier’s name Frédéric Lardeur, APE’s marketing and communications director, said, “45° is the angle made when the barrier boom moves to open the toll lane. When a barrier opens, the boom traditionally makes a 90° angle with the roadway.”

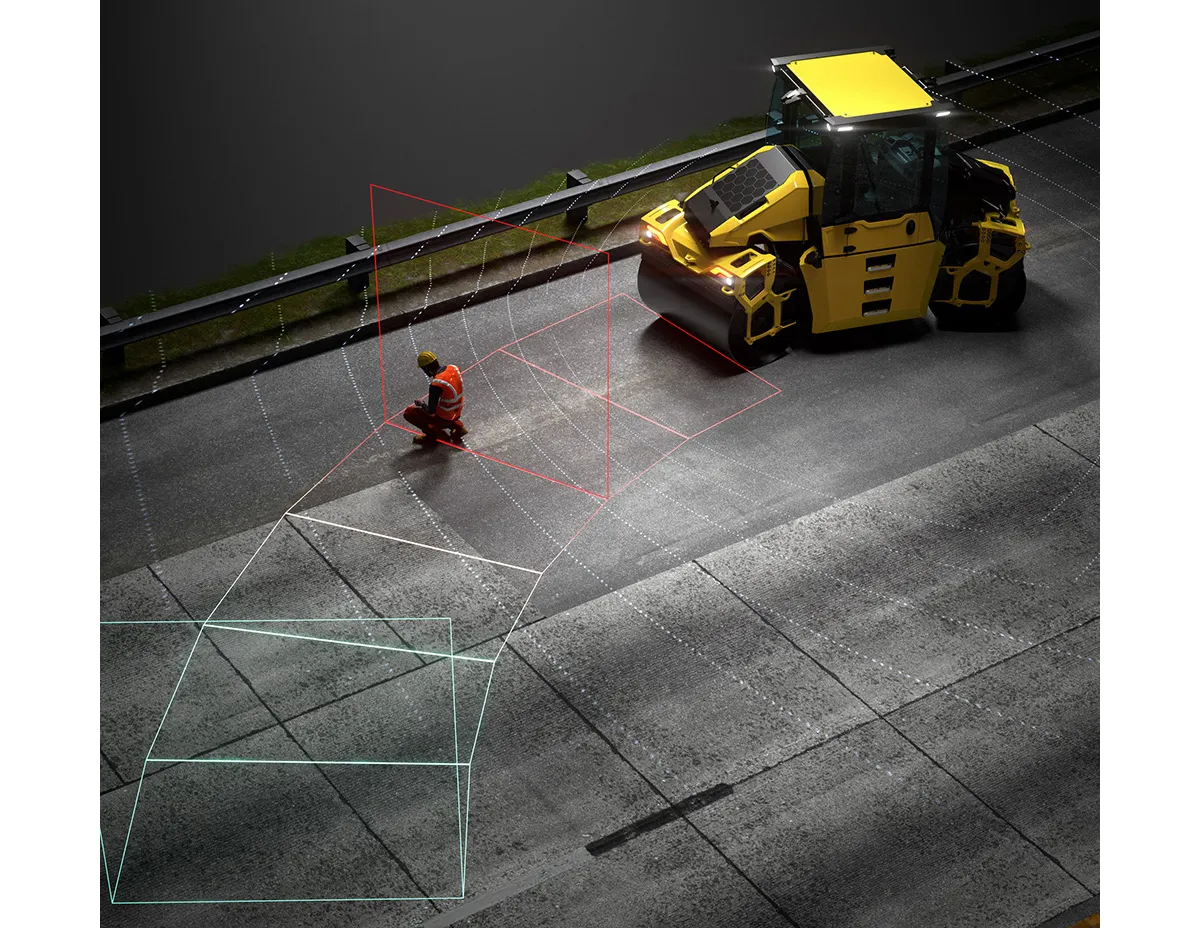

Lardeur said vehicles should not stop for long in toll lanes to keep traffic flowing freely, and stressed how many mechanical and electrical components are required to ensure very short barrier opening times. However, after several million vehicles pass the barriers, their components may become damaged and give way.

“Our Research Department has benefitted from its many years of expertise in the highway sector and the thousands of barriers installed in France, throughout Europe and also Africa,” continued Lardeur. “Reducing the [45] barrier’s opening time was the first objective. To achieve the reduction, APE developed the 45° motion which clears the lanes more quickly with minimum mechanical and electrical effort.”

Robustness and reliability are two essential characteristics for equipment subjected to very high constraints. The 45 barrier’s mechanical and electrical components were submitted to drastic fatigue tests, and its barrier mechanism is said by APE to be guaranteed for over four million operations.

“The 45 barrier is much safer for users than conventional barriers,” added Lardeur. “As a matter of fact, if it is hit by a vehicle the arm moves up and aside with a natural 45° motion. Its movement is stopped by the mechanism and the toll-light fitting. There is no damage to the vehicle and for the operator no boom needs to be replaced.

“To optimise the time a toll employee stands by the barrier, the mechanical and electrical control systems are accessed through the top. All moving parts are totally protected by hoods."

Toll managers already using APE barriers have no need to worry, said Lardeur, as the firm guarantees that all elements of the 45 barrier are compatible with existing installations. Over 90% of the 45’s components are already said to exist in APE’s barrier range.