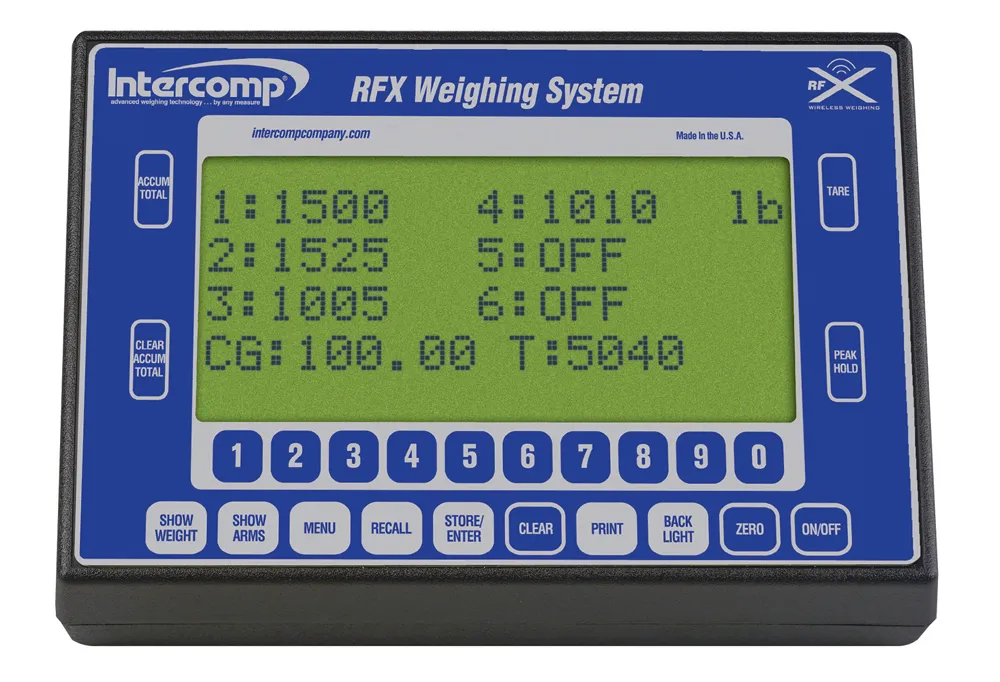

The sophisticated RFX wireless weighing indicator system from Intercomp uses field-proven technology in a compact, hand-held unit. The indicator can be used with any Intercomp RFX scale system and use 2.4GHz wireless frequencies. The wireless indicator can works with up to six scales at once and can be used to control scales remotely from safe distances. Products can be combined to accommodate modular applications for a variety of scenarios. The indicator allows users to show the weights in cumulative total

February 7, 2012

Read time: 1 min

The sophisticated RFX wireless weighing indicator system from 1315 Intercomp uses field-proven technology in a compact, hand-held unit. The indicator can be used with any Intercomp RFX scale system and use 2.4GHz wireless frequencies. The wireless indicator can works with up to six scales at once and can be used to control scales remotely from safe distances. Products can be combined to accommodate modular applications for a variety of scenarios. The indicator allows users to show the weights in cumulative total, individual weights/pad or scale for example. Users can zero scales, change scale and indicator settings, turn scales on or off and calibrate right from the hand-held indicator. The indicator also offers a read-only selection for use with PC software.