Fugro has started scanning structural pavement condition data from lane 2 using Highways England’s Traffic Speed Deflectometer (TSD).

This is the first time for such scanning as part of the routine network-wide survey of England’s strategic roads, according to Fugro.

The global asset integrity specialist has been carrying out Traffic Speed Structural Surveys (TRASS) since autumn 2014 under a 3-year contract (TRASS 3) - Highways England’s largest ever outsourced contract for pavement structural condit

November 14, 2016

Read time: 2 mins

This is the first time for such scanning as part of the routine network-wide survey of England’s strategic roads, according to Fugro.

The global asset integrity specialist has been carrying out Traffic Speed Structural Surveys (TRASS) since autumn 2014 under a 3-year contract (TRASS 3) - Highways England’s largest ever outsourced contract for pavement structural condition data.

TRL, the UK’s Transport Research Laboratory, is providing quality assurance and technical advice on the €1.3 million contract.

To date, Fugro operators have collected and processed TSD data on pavement strength from slip roads and lane 1 of the main line of the primary network.

Fugro said that it has achieved a faster survey rate than anticipated for the first half of the slip roads programme, enabling network-wide completion in the same year. This has accelerated the delivery of TSD data to Highways England to support the assessment and planning of slip road maintenance.

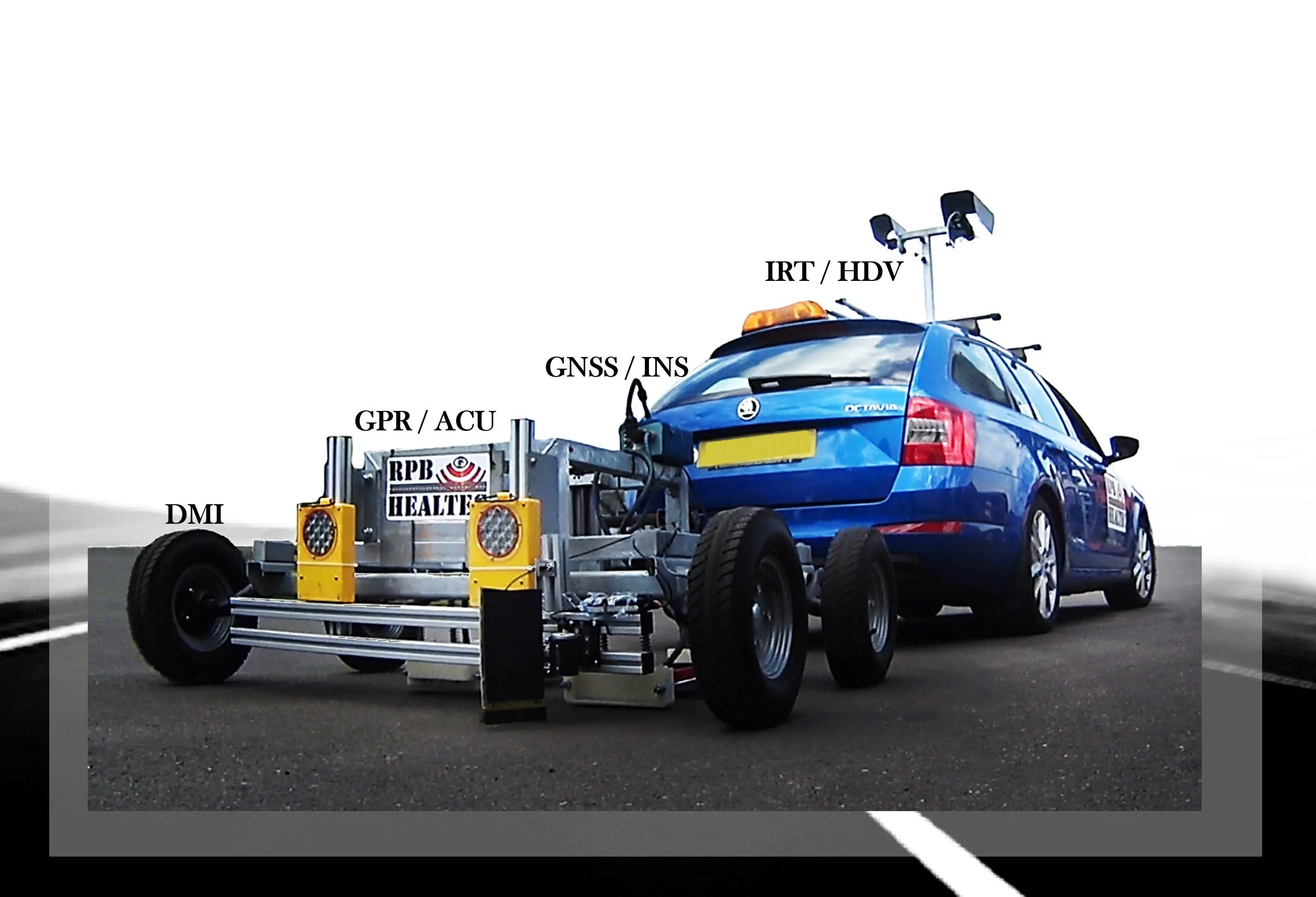

Also for the first time, integrated collection of ground penetrating radar (GPR) data is underway across all 14,000km of carriageways of England’s primary roads. This provides a continuous record of pavement structure and thickness.

The TSD data, with GPR data planned to follow, will be fed into Highways England’s Pavement Management System (HAPMS), enhancing the ability to monitor the condition of pavement assets, prioritise maintenance and improve cost forecasting. The GPR data will be used to interpret deflectometer readings, and for improved quality control and comparative analysis in HAPMS.

The TSD 20-tonne articulated survey truck assesses the structural condition of pavements using contactless Doppler laser technology. The fully automated, computer controlled process working at 80km/h replaces traditional deflectograph surveys carried out at walking pace. As well as improving safety and survey rates, contactless Doppler laser technology brings improved repeatability and quality control to pavement strength assessment.

Fugro undertook the accreditation of the TSD as part of TRASS 3, a vital step in its application for network-wide coverage and delivery of data into a national asset management system.

Road testing of the TSD was carried out in two earlier contracts, TRASS 1 in 2011, followed by TRASS 2 in 2012 which was awarded to Fugro alongside two other contractors.