SWARCO is playing a key role in a US$110 million traffic-management improvement scheme at the UK’s Dover Port

The port handles nearly $155 billion of trade annually and saw record freight volumes of 2.53 million units in 2015, up 5% on 2014. It handles up to 17% of all UK trade so its efficient operation is essential. The object is to control vehicles through a new freight-holding facility to remove 4km of backing up along roads leading into the town and port.

The Port has now created a 13-lane holding zone for 220 outbound heavy goods vehicles (HGVs), reducing the need for Dover Traffic Access Protocol (TAP), a so-called “rolling road” HGV queuing system on the A20 highway into town. It also greatly reduces traffic and delays within Dover town site itself.

Matt Smith, head of structures at FM Conway, said SWARCO worked to extremely tight timescales and programme changes to ensure the project was delivered on time and to budget.

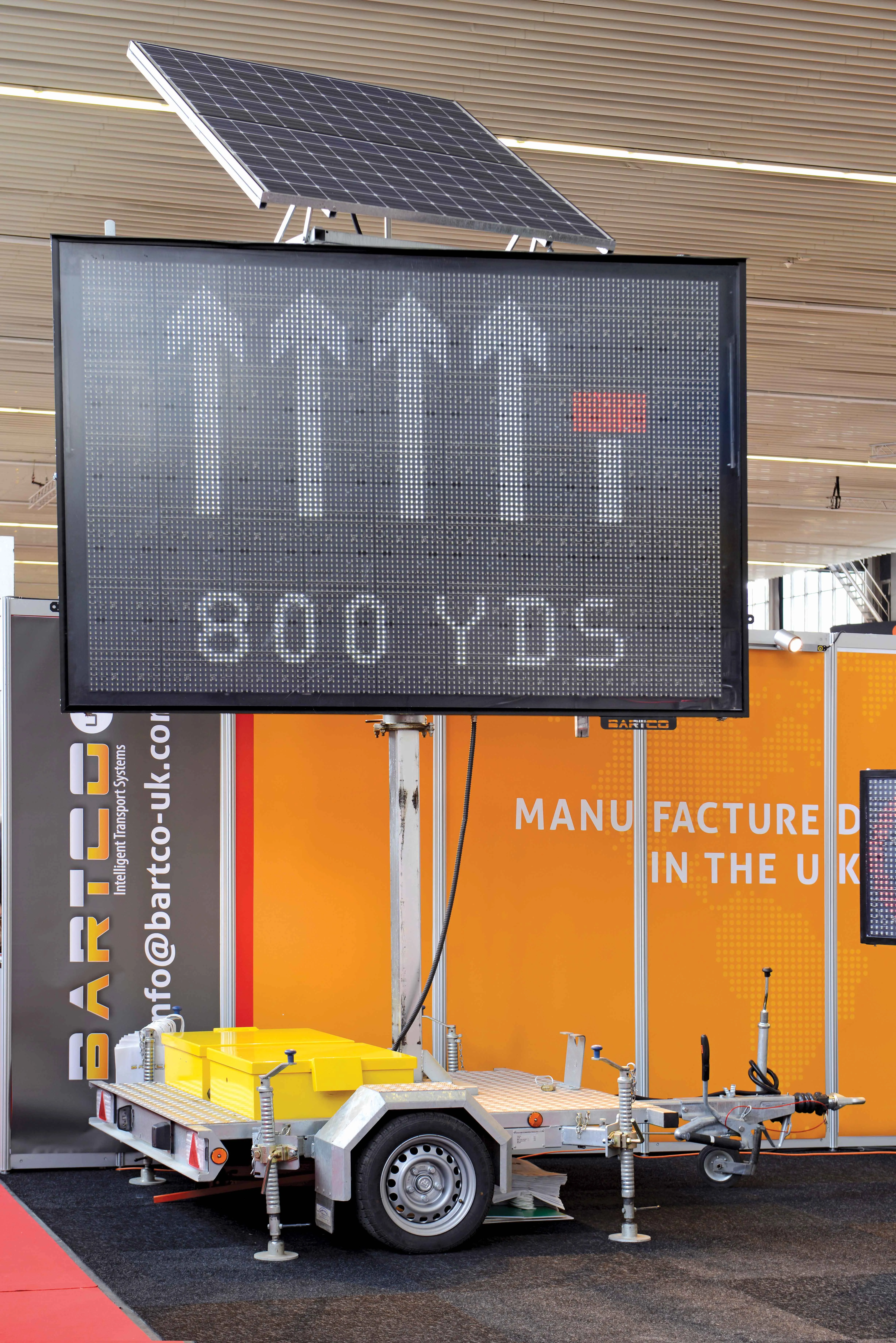

The signs were made to order within three months and include more than 160,000 individual LEDs. The units had to meet the port’s exacting light emission standards to cater for its 24/7 freight needs and reduce light pollution at night.

Also as part of the contract, SWARCO installed its management software, giving the operator 12 settings that can be altered to suit traffic and port administration needs. The system has 65 traffic detection sensors with count in/out capability and barriers operated by a traffic-light system that mark the holding facility’s end.

Tim Waggott, the port’s chief executive, said that the Port of Dover is a crucial link of national and international importance. “That’s why we’ve invested millions in removing old buildings and installing new traffic-management technology and infrastructure to create even more freight-holding capacity.

SWARCO helps cut congestion at Dover Port and local roads

SWARCO is playing a key role in a US$110 million traffic-management improvement scheme at the UK’s Dover Port The port handles nearly $155 billion of trade annually and saw record freight volumes of 2.53 million units in 2015, up 5% on 2014. It handles up to 17% of all UK trade so its efficient operation is essential.

September 29, 2016

Read time: 2 mins