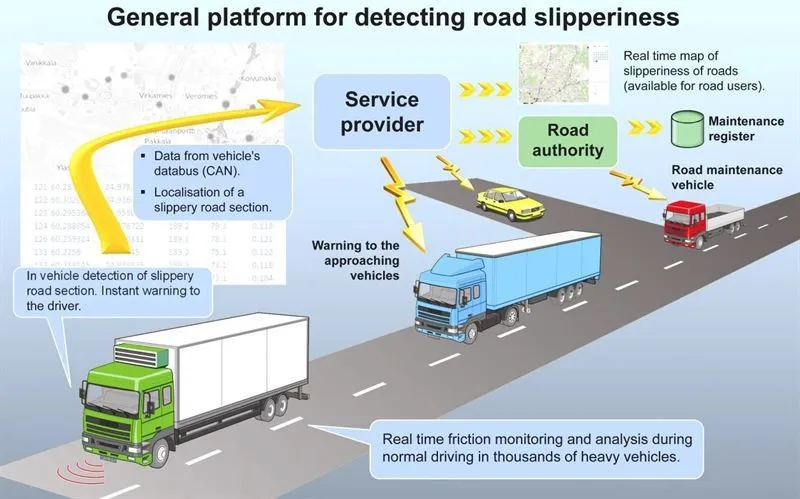

Winter road maintenance could be getting more efficient, thanks to the Grip, a black ice detection system from two Finnish research organisations.

The Grip allows drivers to detect in real-time slippery road conditions extremely accurately and with costs significantly lower than by any other methods already being used, according the two firms –

A commercial vehicle has the software to detect a slippery road surface and has as transmitter to send out the warning signal to other commercial drivers equipped with receiving equipment. Receivers could also be installed in passenger vehicles and – importantly – road maintenance vehicles which could respond immediately to section of road in question.

The detection software analyses information collected from the vehicle data bus and from which it estimates road surface friction. The Grip system examines the difference between the rotational speeds of free-rolling wheels and driving wheels, and, when making calculations, takes the engine power into account. The result of this provides the slip ratio, which, in theory, increases in correlation to the degree of road surface slipperiness.

In winter 2015-2016, four tests were performed using tanker trucks and three tests using buses. According to the test results, the companies believe that the Grip method might prove more cost-effective for determining black ice and slippery roads in general than the system abandoned by the Finnish Transport Agency in 2011. In that system, consultants were hired to drive a vehicle equipped with friction meters along pre-determined, pre-scheduled routes.

The added value is increased safety for road users because they are alerted to slippery conditions before arriving on the section with less traction.

VTT Technical Research Centre of Finland is a state-controlled not-for-profit manufacturing research company in the city of Espoo, about 20km west of the capital Helsinki. Its projects are funded part by government and part by industry.

EEE Innovations, based in the city of Lohja about 60kmk west of Helsinki, focusses on traffic safety efficiency services that use processed data for traffic weather service providers and road maintenance services as well as providers of public transport and heavy traffic services.

As well as VTT, EEE Innovations has close links with Turku University of Applied Sciences, Aalto University, as well as Tampere University of Technology and University of Tampere. EEE Innovations also produces eDAS, a real-time system to reduce energy consumption of buses and to keep the vehicles on schedule.