A new project aims to bring Europe to the forefront of developing the future of transport. A three-year project has set itself the challenge of developing a "truly inspiring vision" of how roads will be built and maintained in the 21st century. Forever Open Road is a revolutionary concept led by the Forum of European National Highway Research Laboratories (FEHRL) and supported by the UK's influential TRL (Transport Research Laboratory).

February 14, 2012

Read time: 4 mins

A new project aims to bring Europe to the forefront of developing the future of transport

A three-year project has set itself the challenge of developing a "truly inspiring vision" of how roads will be built and maintained in the 21st century. Forever Open Road is a revolutionary concept led by theIt aims to bring together the best of today's technology with the best of what is to come, and produce the fifth generation road: a road that is adaptable, automated and climate change-resilient (whether motorway, rural or urban, and regardless of region or country).

"By bringing together innovative technologies and concepts, and by harvesting knowledge and expertise from across Europe this new generation road will transform the way roads are built, designed, maintained and operated. It will also bring Europe to the forefront of developing the future of transport," says FEHRL.

"The Forever Open Road will tackle global challenges such as climate change, carbon reduction, energy saving, as well as the increasing need for journey time reliability in response to rising demand both for private car travel and the delivery of goods by road. At the same time, it will help meet European goals to provide transport infrastructure that is safe and secure; cleaner, quieter and more energy efficient; highly competitive and sustainable; provide enhanced mobility based on optimised, efficient seamless systems."

The phasing of the programme of research will take the project through from concept development to demonstration projects and monitoring and working towards full-scale trials of both the individual elements and the complete concept.

The project will be carried out in four phases with phase 1, the concept development, being completed this year. The second phase, scoping the research and development will be completed by 2011; Phase 3 (development of the three elements, 2013), and Phase 4 (demonstration projects and monitoring, from 2013 onwards).

The first phase of the programme is being taken forward by FEHRL members from

"The Forever Open Road will encourage Pan-European engagement and collaboration, and stimulate research across the member states bringing cost savings and benefits for all. It will also bring together public and private sector organisations with expertise in road design, travel behaviour, road safety, intelligent transport systems, vehicle manufacture, environmental impact and product manufacturing," says FEHRL.

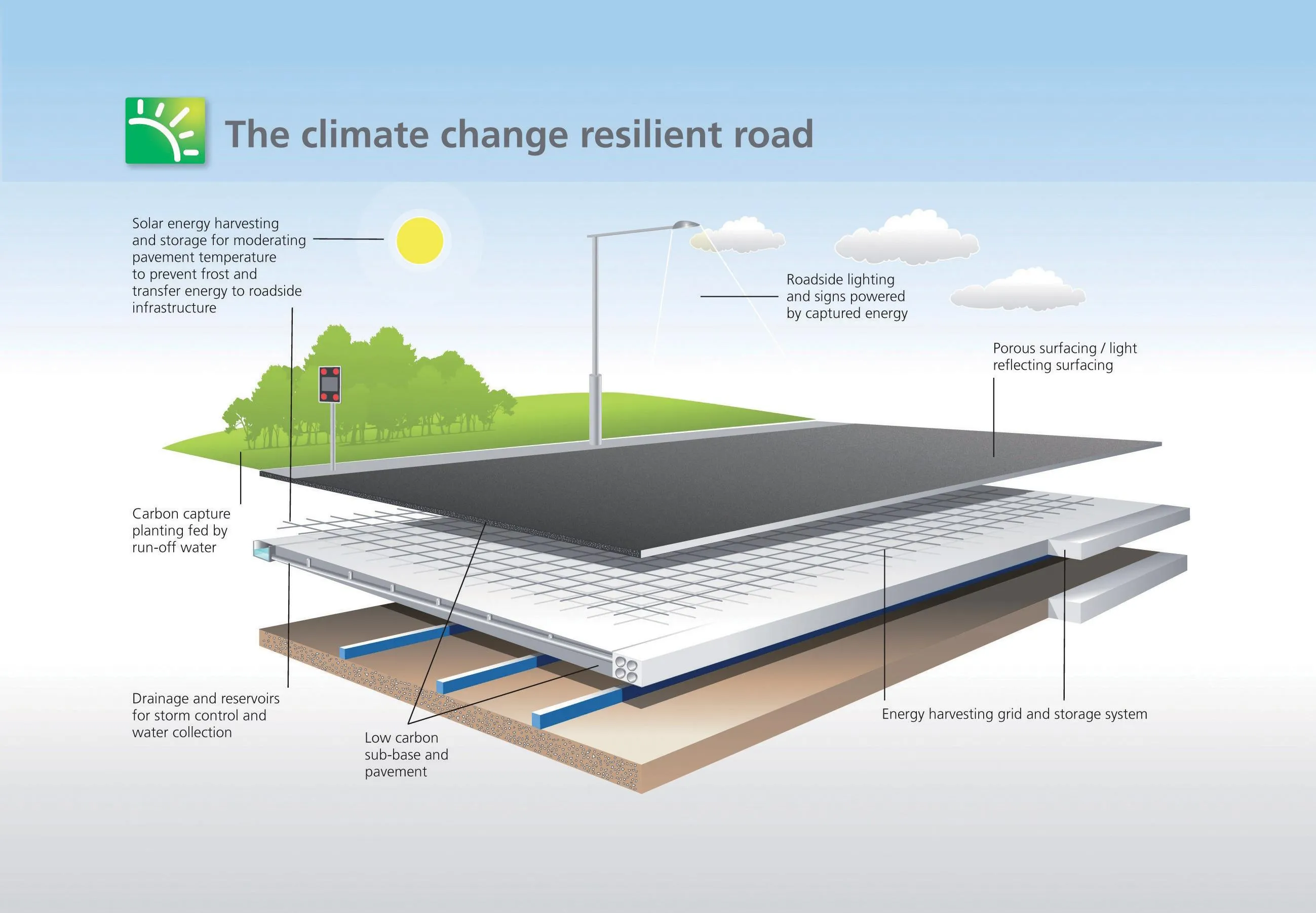

According to FEHRL, the road would adapt to future maintenance, changing capacity demand and vehicle manufacturer needs; it would automatically provide in-built vehicle guidance as well as travel information and performance measurement; it will be built from sustainable materials; will harvest, store and use energy; will cope with excess water and temperature change, and will be able to clean and repair itself.

"The overall aim would be for roads to be Forever Open, with minimum intervention for repairs and widening or for new installations or for dealing with weather hazards. The key to this new approach will be the adaptable element, formed of prefabricated, upgradable pavement structures that retain long life regardless of the need for upgrades and interventions. The adaptable element will accommodate the automated and climate change resilient elements." However, FEHRL says there will be challenges, not least because some of the obstacles to be overcome are as yet unknown.

"What is certain is that Europe's central forum for highway research, FEHRL, can provide the leadership and motivation that is needed to deliver a programme of research with such a wide scope for innovation and with such a potential for the development of new products, methods and specifications.

Organisations wishing to become involved in the project can contact:

Patrick Malléjacq (LCPC)

Tel: +33 1 4043 5028

Email: patrick.[email protected]

Steve Phillips (FEHRL Secretary-General)

Tel: +32 2 7758245

Email: [email protected]

Bob Collis (TRL)

Tel: +44(0)1344 773131

Email: [email protected]