Productive highway line marking removal is possible with the new Starjet-Plus model from NLB. Featuring a novel water jet system, this machine helps contractors remove more pavement marking or runway rubber/shift than before. This is said to be the first high-pressure water jet system featuring on-board filtration, allowing users to fill the water tank once and work all day without stopping to refill.

February 24, 2012

Read time: 2 mins

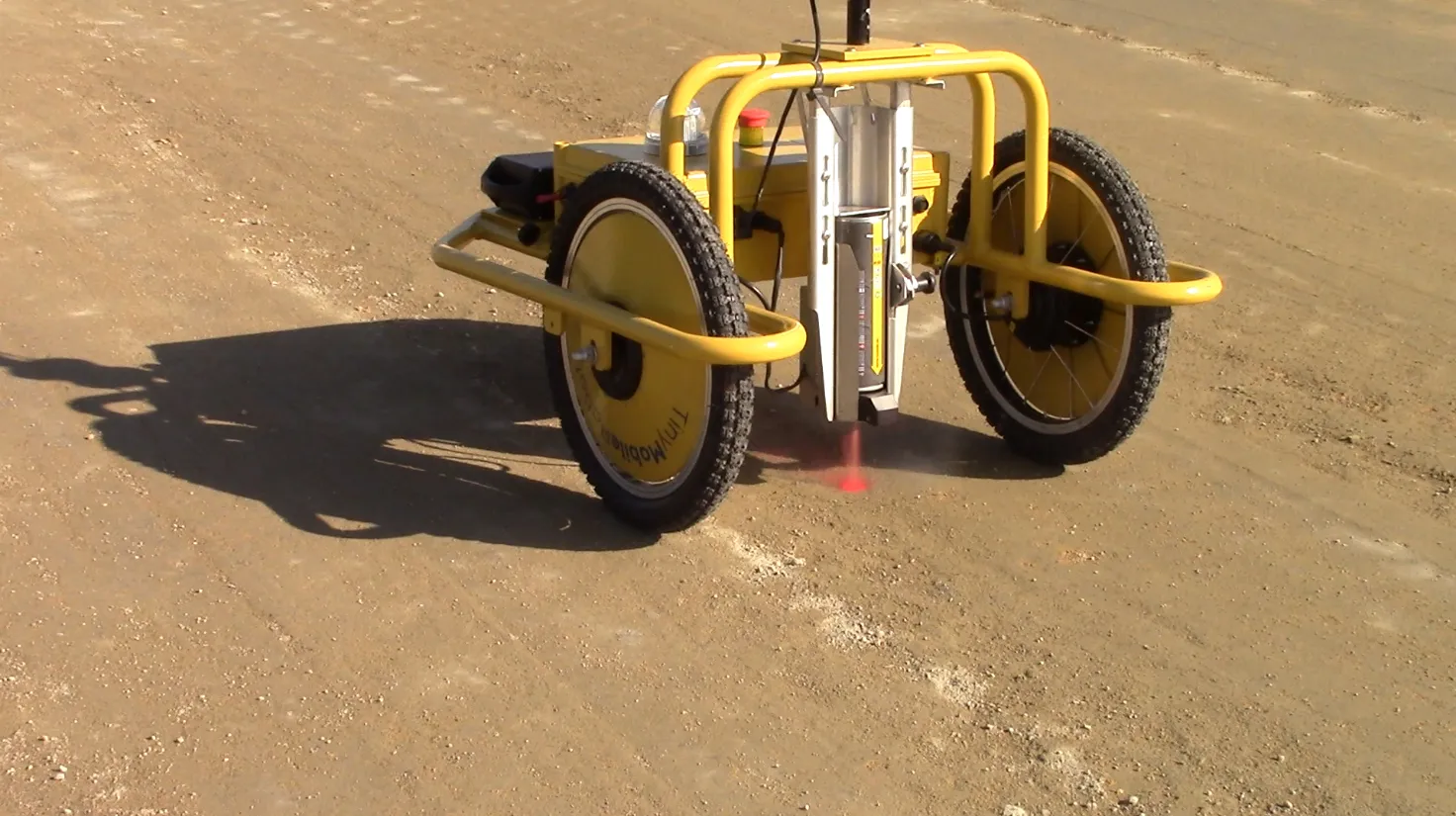

Productive highway line marking removal is possible with the new Starjet-Plus model from 3134 NLB. Featuring a novel water jet system, this machine helps contractors remove more pavement marking or runway rubber/shift than before. This is said to be the first high-pressure water jet system featuring on-board filtration, allowing users to fill the water tank once and work all day without stopping to refill. This can save two hours of downtime/eight hour shift, speeding up project completion.

This is a closed-loop system with rotating water jets on a robotic arm that is mounted to the front of a flatbed truck. The high pressure water jets remove markings or curing compound as the truck drives along the road, or remove rubber as it drives along the runway. This is faster and more effective than grinding and does not damage concrete or asphalt.

The system offers features not previously available including proportional controls on the robotic arm for more speed and better control, in-cab video to let the driver view progress and surrounding traffic and three levels of waste and debris handling.

The Starjet-Plus is not powered by the carrier vehicle's engine and each self-contained unit includes a high pressure pump unit, water tank, patented rotating nozzle assembly, integrated vacuum recovery and cab-mounted controls. Customers can also order certain modifications from NLB if required.

This is a closed-loop system with rotating water jets on a robotic arm that is mounted to the front of a flatbed truck. The high pressure water jets remove markings or curing compound as the truck drives along the road, or remove rubber as it drives along the runway. This is faster and more effective than grinding and does not damage concrete or asphalt.

The system offers features not previously available including proportional controls on the robotic arm for more speed and better control, in-cab video to let the driver view progress and surrounding traffic and three levels of waste and debris handling.

The Starjet-Plus is not powered by the carrier vehicle's engine and each self-contained unit includes a high pressure pump unit, water tank, patented rotating nozzle assembly, integrated vacuum recovery and cab-mounted controls. Customers can also order certain modifications from NLB if required.