Over the past four years, there have been nine road worker deaths on the Highways Agency network in the UK. Statistics such as these are drivers for road authorities to improve health and safety for the workforce on the network.

It takes just seconds to replace a Stimsonite Click Stud reflector compared to an average time of eight minutes to remove and replace a conventional bonded road stud. This greatly benefits the Highways Agency by reducing the exposure of road workers to traffic.

Conventional

April 29, 2015

Read time: 2 mins

Over the past four years, there have been nine road worker deaths on the 2309 Highways Agency network in the UK. Statistics such as these are drivers for road authorities to improve health and safety for the workforce on the network.

It takes just seconds to replace a Stimsonite Click Stud reflector compared to an average time of eight minutes to remove and replace a conventional bonded road stud. This greatly benefits the Highways Agency by reducing the exposure of road workers to traffic.

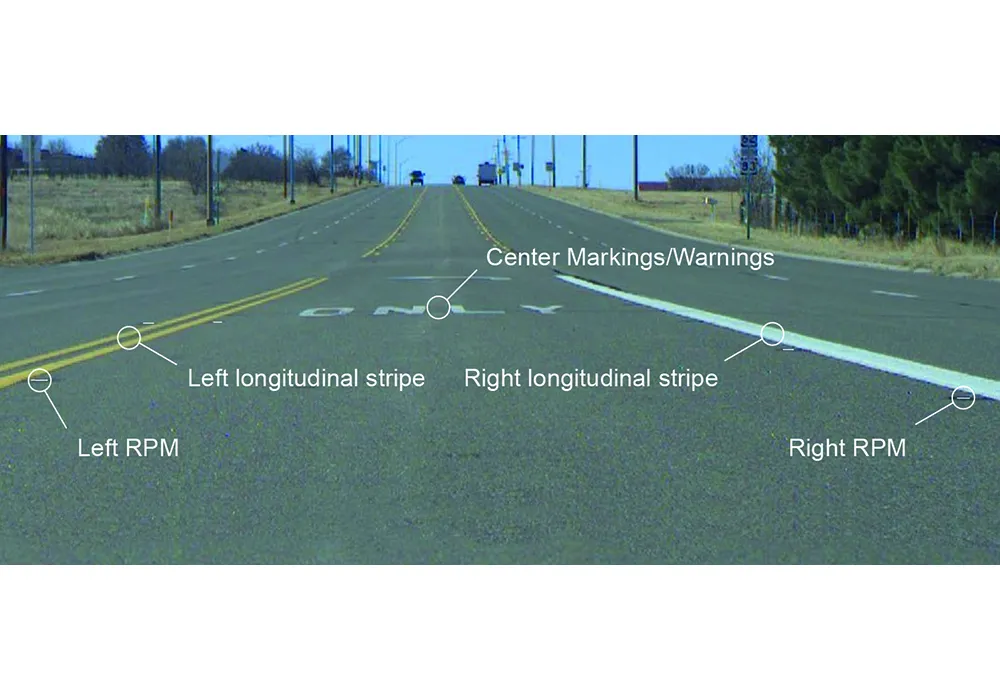

Conventional reflective road studs are typically assembled using adhesive to fix the reflector in the housing. The bonded assembly provides good durability and working life for the reflector. However, when the reflector needs to be replaced, the bonding method of assembly makes the replacement process time consuming and expensive. Removing the old reflector, cleaning the recess and refitting with adhesive is laborious and time-consuming. Extended road closures are required causing unnecessary disruption and risk to the work force.

The novel Stimsonite Click Stud has a patented fixing system that allows rapid removal and replacement of the reflector in-situ in the road surface. Due to the reduced traffic management costs as well as the fast, cost-effective reflector replacement, the Stimsonite Click Stud has a lower whole life cost compared to any other product currently on the market.

At times of surface dressing the reflector can be removed and clicked back in place once the work is completed. Labour and traffic management costs are estimated to be two thirds of that of conventional units, while traffic disruption is reduced and lane closures will be shortened. The reflector can also be removed and replaced with blanks during roadworks when there are lane movements or priority change, to help avoid road user confusion with lane delineation. Once the works are complete the process can be quickly reversed, saving time and money and these units are already being used in the UK on the M25, A14 and M74.

It takes just seconds to replace a Stimsonite Click Stud reflector compared to an average time of eight minutes to remove and replace a conventional bonded road stud. This greatly benefits the Highways Agency by reducing the exposure of road workers to traffic.

Conventional reflective road studs are typically assembled using adhesive to fix the reflector in the housing. The bonded assembly provides good durability and working life for the reflector. However, when the reflector needs to be replaced, the bonding method of assembly makes the replacement process time consuming and expensive. Removing the old reflector, cleaning the recess and refitting with adhesive is laborious and time-consuming. Extended road closures are required causing unnecessary disruption and risk to the work force.

The novel Stimsonite Click Stud has a patented fixing system that allows rapid removal and replacement of the reflector in-situ in the road surface. Due to the reduced traffic management costs as well as the fast, cost-effective reflector replacement, the Stimsonite Click Stud has a lower whole life cost compared to any other product currently on the market.

At times of surface dressing the reflector can be removed and clicked back in place once the work is completed. Labour and traffic management costs are estimated to be two thirds of that of conventional units, while traffic disruption is reduced and lane closures will be shortened. The reflector can also be removed and replaced with blanks during roadworks when there are lane movements or priority change, to help avoid road user confusion with lane delineation. Once the works are complete the process can be quickly reversed, saving time and money and these units are already being used in the UK on the M25, A14 and M74.