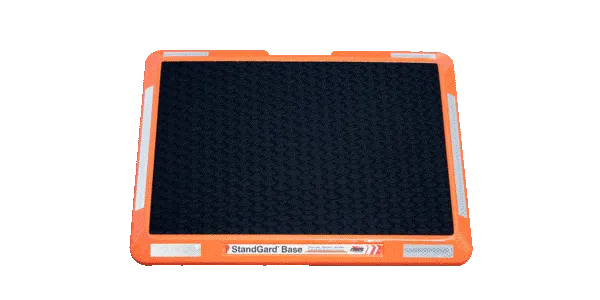

PSS claims that its StandGard Base Portable Standing Station protects workers against exposure to excessive temperatures, like overheating in hot weather, or body heat loss in cold weather. With an R-Value of six, StandGard reduces the transference of heat and cold from roadway surfaces, better protecting workers.

When compared to shoes alone, PSS claims that its StandGard Base Portable Standing Station allows workers’ feet to remain cooler in hot weather and warmer in cold. With almost 2,800cm² of standing area, StandGard’s anti-fatigue mat also reduces wear on feet, knees and backs.

StandGard is especially useful if the flagger is operating in recently laid pavement that remains hot and which can damage footwear, notes the company.

When outdoors, stationary workers stand in a predictable, consistent location so drivers can more readily see them. StandGard provides a “home base” – a defined area from which workers, for their safety, should not drift away, especially if they are operating in close proximity to traffic.