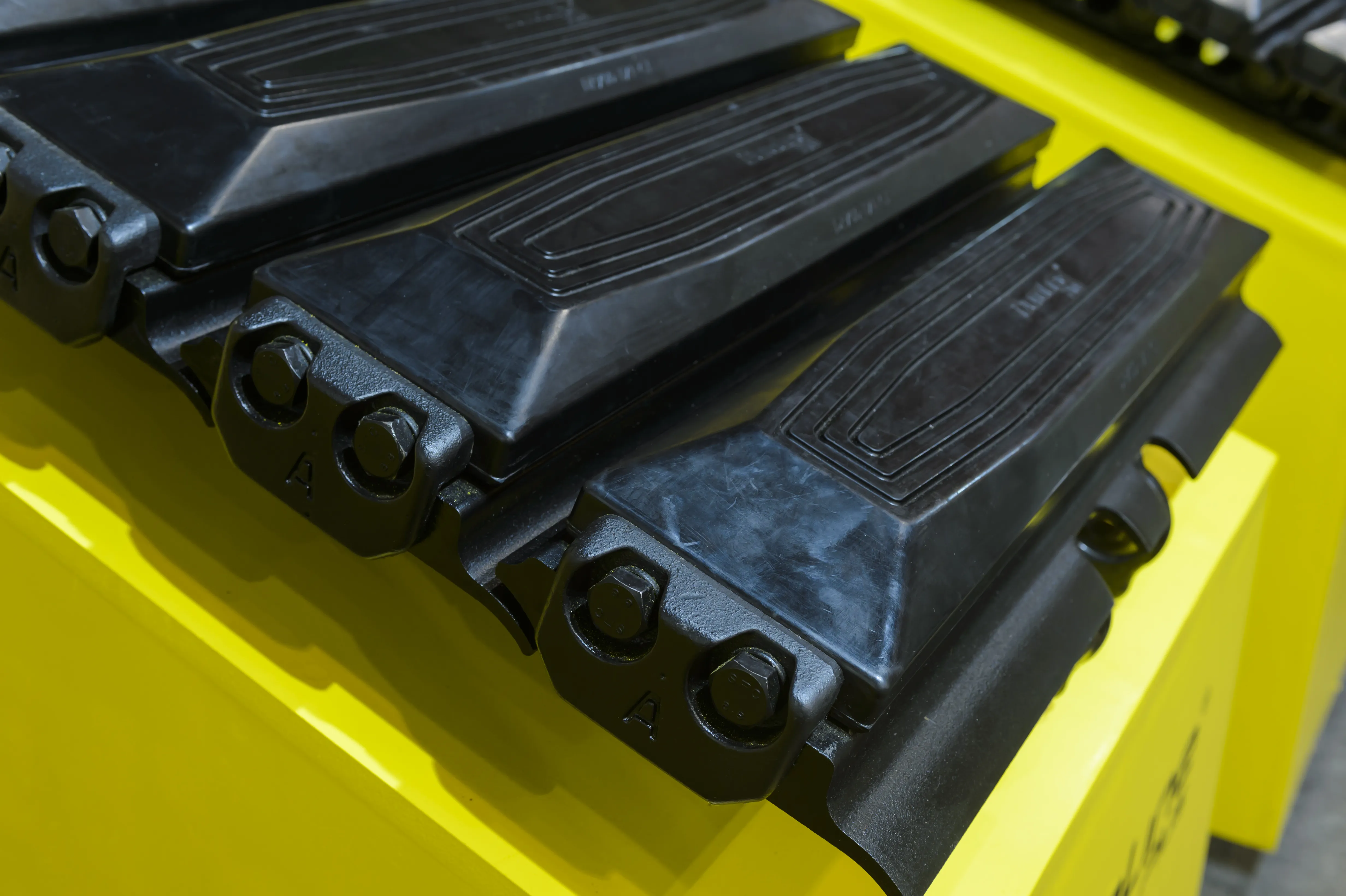

The HEART - Hybrid Energy-absorbing Reusable Terminal - uses high molecular weight/high density polyethylene (HMW/HDPE) side panels and a rounded frontal nose piece. These are connected to steel diaphragms mounted on tubular steel tracks.

The company said that HEART’s HMW/HDPE panels and nose reduce life cycle costs and minimise maintenance. Anchor bolts are easily accessible without the removal of side panels or diaphragms.

The units, which arrive fully assembled, can be installed on new or existing concrete pads. The open design facilitates easier installation, inspection and repair.

Trinity uses several independent test facilities to conduct crash tests for product approval required by the

HEART of the matter from Trinity Highway Products

The HEART is a reusable, restorable, non-gating and re-directive crash cushion manufactured by Trinity Highway Products, based in Dallas in the US state of Texas.

The HEART - Hybrid Energy-absorbing Reusable Terminal - uses high molecular weight/high density polyethylene (HMW/HDPE) side panels and a rounded frontal nose piece. These are connected to steel diaphragms mounted on tubular steel tracks.

The company said that HEART’s HMW/HDPE panels and nose reduce life cycle costs and minimise maintenance. Anc

December 13, 2018

Read time: 2 mins

The HEART is a reusable, restorable, non-gating and re-directive crash cushion manufactured by 7402 Trinity Highway Products, based in Dallas in the US state of Texas.