SRB is highly visible with a noticeable colour and self-luminescence which alerts drivers – especially at night - to the danger of that particular curve or stretch of road. The system can be used as a median barrier or roadside barrier.

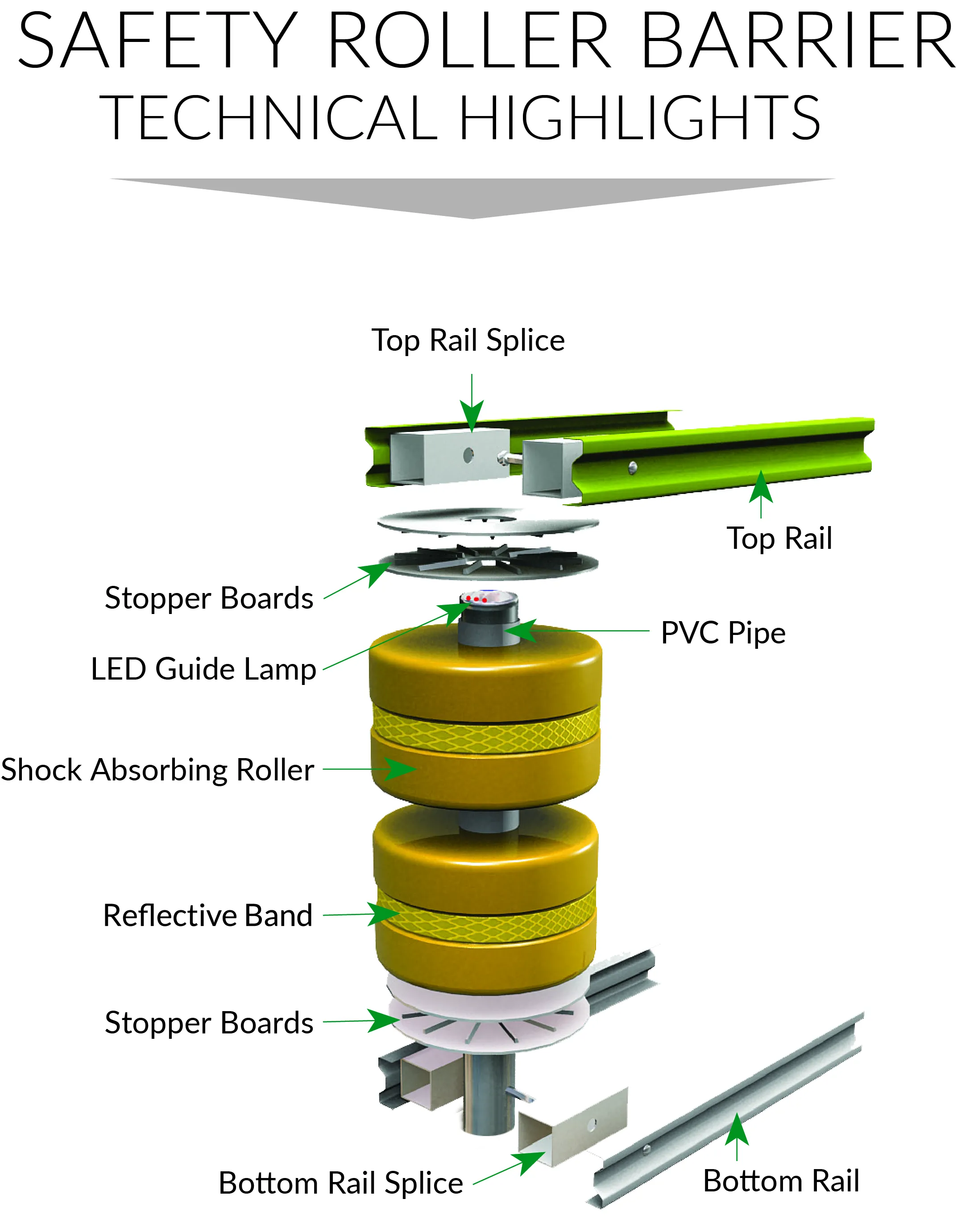

The SRB, manufactured by the South Korean company Evolution in Traffic Innovation, consists of rotating barrels made of ethylene-vinyl acetate that are aligned within a continuous metal frame. Ethylene-vinyl acetate has better shock absorption characteristics than rubber or urethane.

Upon impact by a vehicle, the barrels rotate to convert shock energy from the vehicle into rotational energy. This propels the vehicle forward back onto the road instead of crashing through the barrier or becoming entangled in a destroyed barrier system.

Gregory launched the SRB into the North American market at the 2017 ATSSA Traffic Expo in Phoenix, Arizona, in February. The company said that it is working with several states to develop pilot projects and complete installations.

Gregory Industries is the exclusive North American distributor also for the Guardian 5 (G5) – MASH TL-5 longitudinal barrier system.

The strong and flexible MASH TL-5 longitudinal barrier is designed to safely capture and redirect a fully loaded 36,290kg vehicle. The company said that the G5 is a cost-effective and safer alternative to concrete barriers and is intended for use in areas of high congestion and median cross-over accidents.