DynaWall’s main application is for use during road construction where it can assist in traffic management by shifting traffic lane barriers. The system can move up to 1,000m of safety barriers within minutes without the need of heavy-duty equipment. The system’s manufacturer, Swiss company DynaRoads, does not make the barriers. But the system is designed to be flexible enough to be used with the majority of barrier types, says Cindy Duerst, who handles international sales. The method to move the wall – any

July 5, 2016

Read time: 2 mins

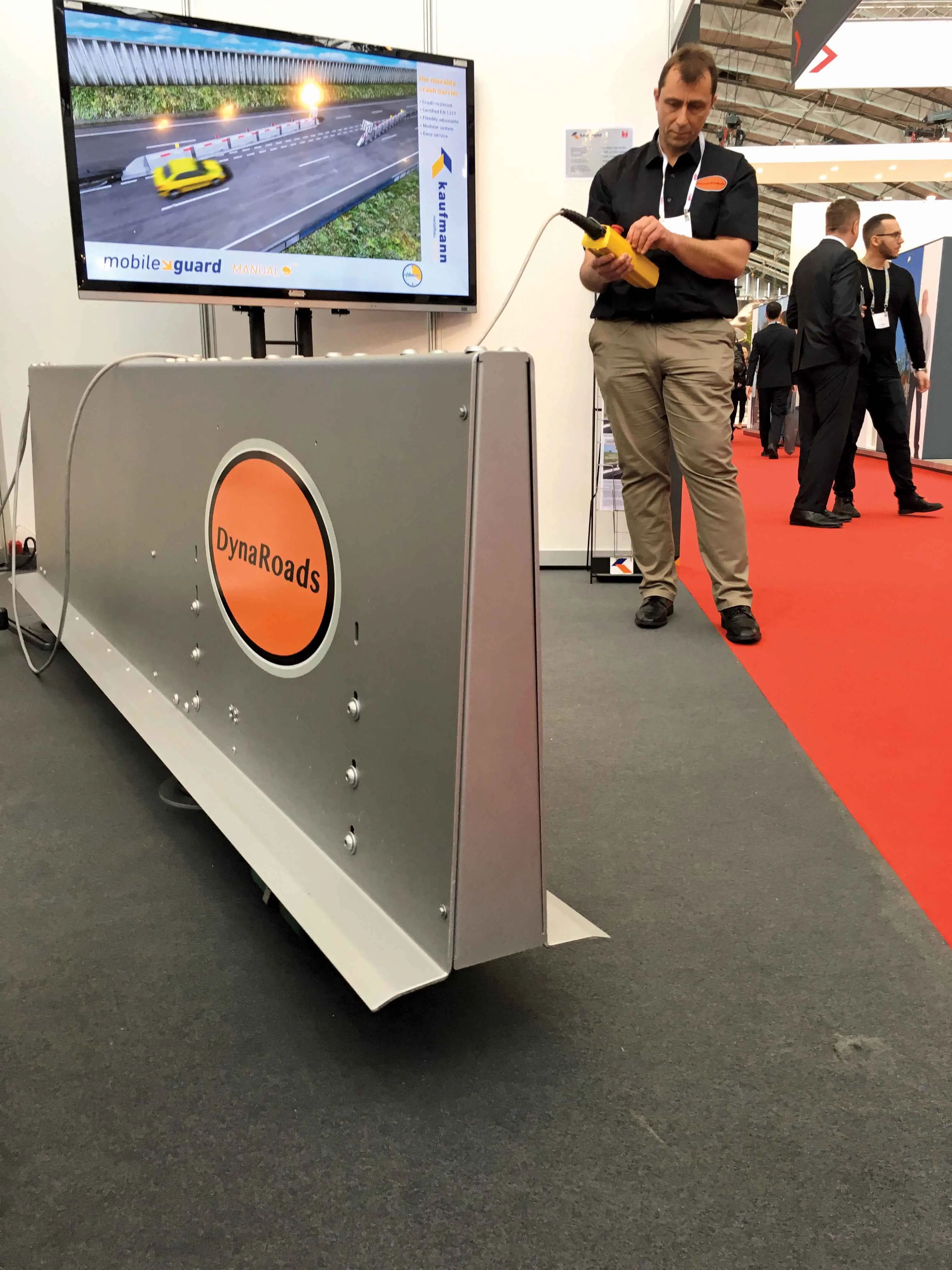

DynaWall’s main application is for use during road construction where it can assist in traffic management by shifting traffic lane barriers. The system can move up to 1,000m of safety barriers within minutes without the need of heavy-duty equipment.

The system’s manufacturer, Swiss company DynaRoads, does not make the barriers. But the system is designed to be flexible enough to be used with the majority of barrier types, says Cindy Duerst, who handles international sales.

The method to move the wall – any kind of temporary safety guard barrier – is an electro-hydraulic powered retractable and folding chassis. Essentially, this is a series of small self-crawling wheeled units installed every 10-20m underneath the barrier. Each unit is powered by a 24V rechargeable battery pack.

A hand-held control unit simply plugs into the side of the barrier in order to send messages to the unit to raise the barrier off the ground and then travel in a particular direction.

The system’s manufacturer, Swiss company DynaRoads, does not make the barriers. But the system is designed to be flexible enough to be used with the majority of barrier types, says Cindy Duerst, who handles international sales.

The method to move the wall – any kind of temporary safety guard barrier – is an electro-hydraulic powered retractable and folding chassis. Essentially, this is a series of small self-crawling wheeled units installed every 10-20m underneath the barrier. Each unit is powered by a 24V rechargeable battery pack.

A hand-held control unit simply plugs into the side of the barrier in order to send messages to the unit to raise the barrier off the ground and then travel in a particular direction.