The introduction of autonomous technology to an impact protection vehicle removes the driver from a potentially dangerous situation should the impact be sufficient to cause injuries or death. The vehicle is a joint US-UK project. It was developed in the US by Micro Systems Incorporated – a division of Kratos Defense & Security Solutions – and

The group approached

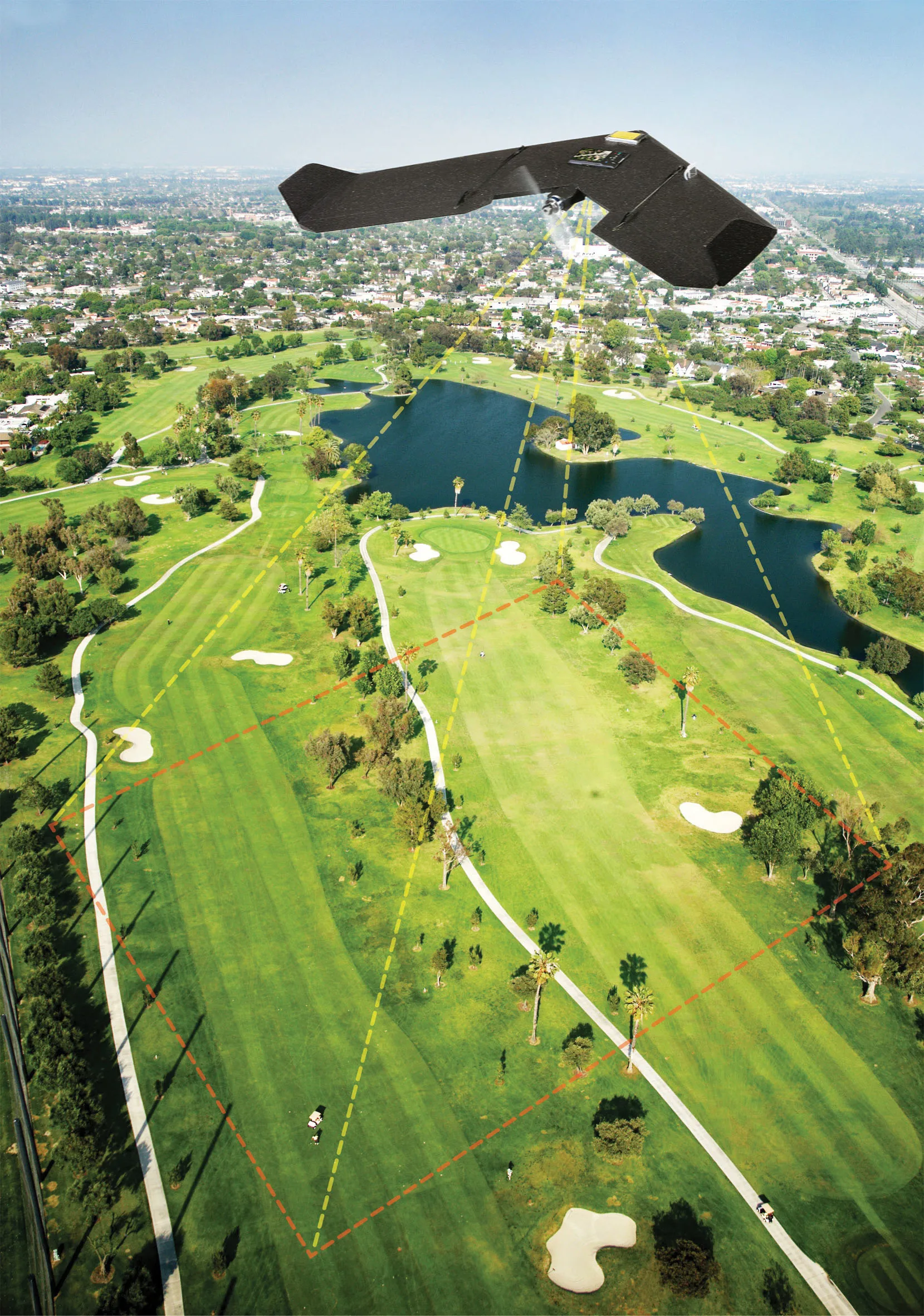

The autonomous vehicle is fitted with Micro System’s electro-mechanical Multi-Platform Appliqué Kit (M-Pak), a fully integrated sensor suite. It includes a roof-mounted navigation module, a quick-install steering actuator, actuators for acceleration and braking, transmission controller and an active safety system. M-PAK is a scalable system so it can be used as a stand-alone vehicle mobility kit, or sensors can be added to offer various levels of autonomy.

The lead vehicle – in this case a line-painting truck - with its driver has a roof-mounted NAV that contains a GPS receiver, system computer, digital compass and a transceiver. It transmits GPS position data called eCrumbs back to the follower vehicle, which then uses the data to track along the exact path and speed of the lead vehicle at each point along the route. The NAV Module can be easily unstrapped and removed from one vehicle and installed on another if a different lead vehicle is required.

Royal Truck and Equipment, founded in 1982, is a large manufacturer of truck-mounted attenuators and other safety vehicles based in Coopersburg, Pennsylvania.

Micro Systems, wholly owned by Kratos, is based in Fort Walton Beach, Florida. MSI develops unmanned vehicle technology, command-and-control systems and other vehicle management systems for all types of military use.