Trials of a new unit from

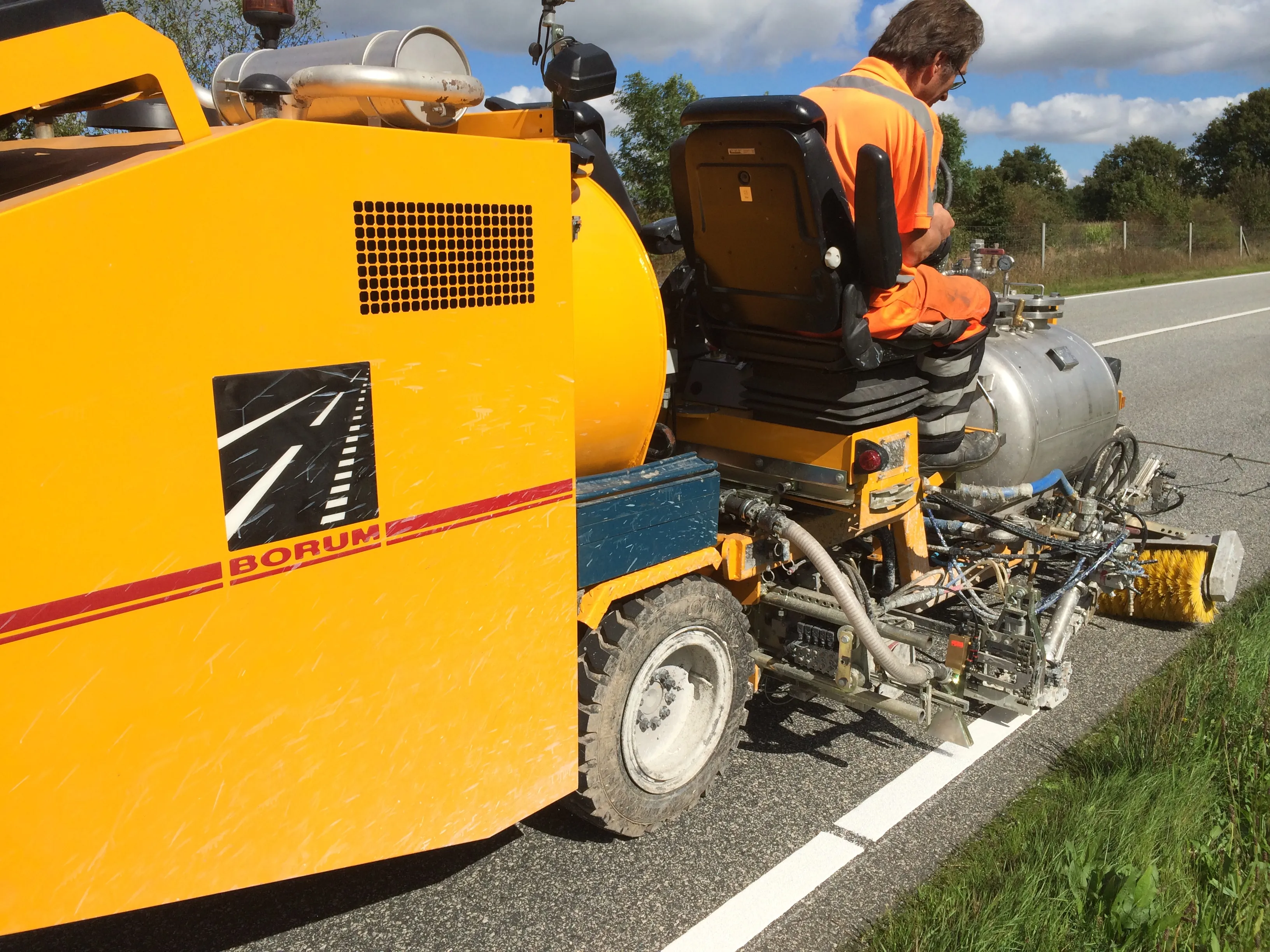

The work was carried out by the local specialist contractor ABV over a two-day period to evaluate the performance of the machine. The unit was able to carry out the job as required and installed markings over a distance of some 22.5km, laying 2tonnes of the 2K material specified by the needs of the job.

Productivity was said to be high and the machine achieved a working rate of 4.2km/h while installing a 120mm line. This working trial of one of the latest models in the range comes at an interesting time for the company. Borum says it has recently put in place its planned transition to new ownership, following the sale of a majority shareholding by its owner, Ole Munch, to a small group of Danish investors. The company says that this move is intended to strengthen its future development through growing commercial opportunities worldwide. Borum is now headed by its new CEO, Ib Neustrup Simonsen, with the company making growth core to its operations. The plans call for a stronger presence in existing markets, as well as the development of new products, and the development of new markets for its range of solutions. With this plan the company says it will foster stronger relations with its existing dealers, as well as moving into the many new markets, where infrastructure is transitioning to modern standards and there is a demand for the latest technology.