Absorb-M is non-redirective system that is tested to the American Association of State Highway and Transportation Officials (AASHTO) Manual for Assessing Safety Hardware (MASH) Test Level TL-2 and TL-3 standards. The system is "work zone ready", says the company, based in the US state of Nebraska. It is suited for narrow areas where road and workspace is limited.

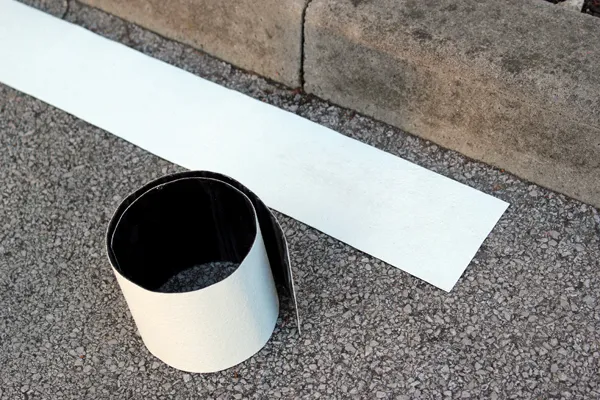

Absorb-M is 61cm wide and uses interchangeable stackable elements to reduce inventory costs, explained Scott Marion, president of infrastructure at Lindsay Corporation. Each element is equipped with accessible forklift points that allow for easy pick up. A TL-3 rated system uses only three elements, making installation among the quickest and easiest in the industry, says Lindsay. Its universal transition adapts to most portable or permanent barriers.

Other features and benefits include rapid deployment and retrieval as well as anchorless installation, meaning no foundation is required. It is built for use on almost any road surface and is suited for both anchored and unanchored barriers.

As with all of Lindsay Transportation Solutions’ MASH-tested systems, Absorb-M comes with installation instructions, online installation courses, mobile-friendly installation videos and a worldwide network of distributor partners. Lindsay also has field service technicians available to assist uses of the system.