Taiwan-based Apus Molds and Plastics (AMP) says it has developed a ‘novel’ poly carbonate barrier system. Made from PC and PP materials, the barrier is said to be long lasting and corrosion resistant, as well as being lightweight and quick to install. Impact performance is also said to be good as the material helps absorb shock.

June 15, 2012

Read time: 2 mins

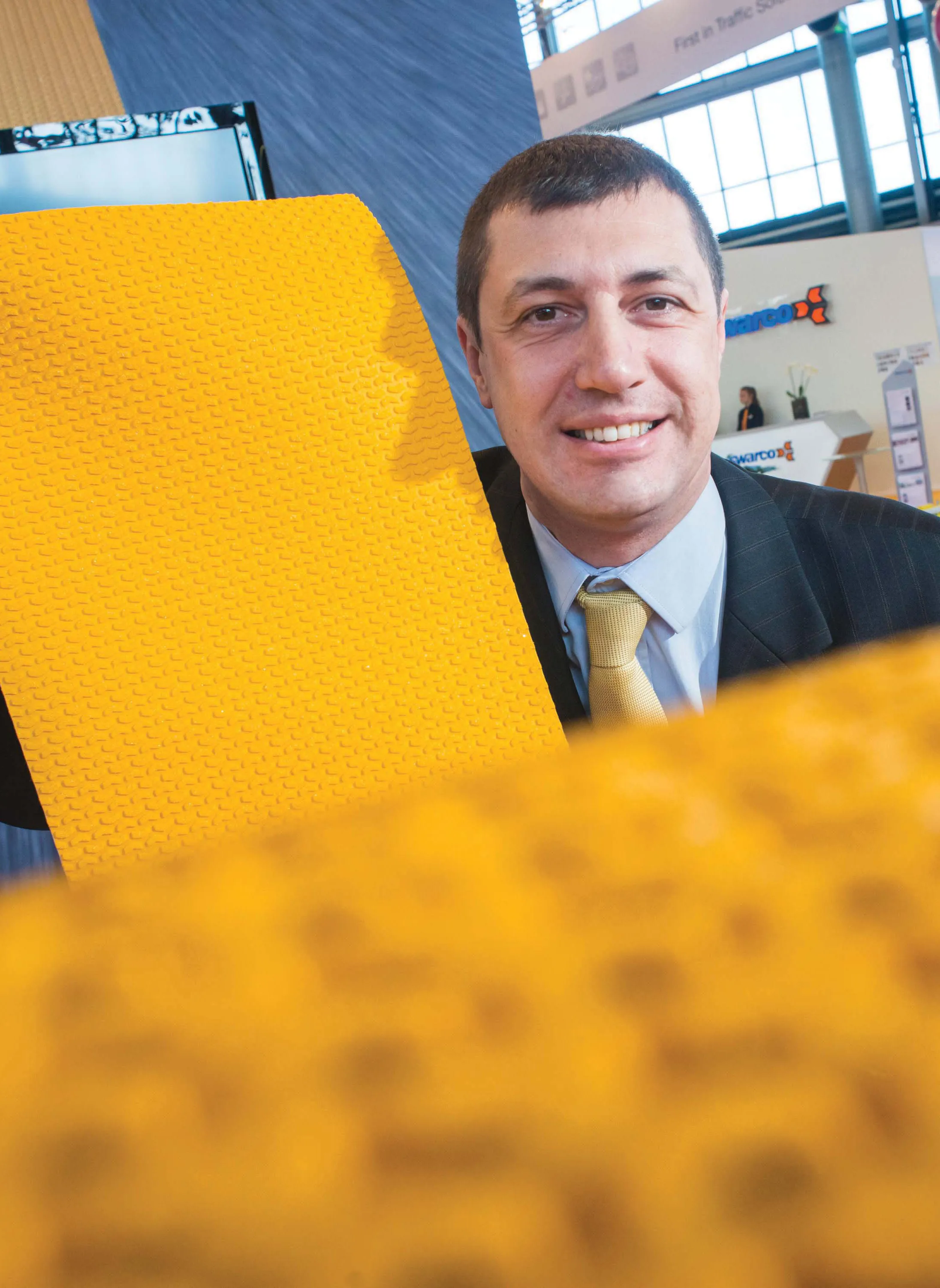

Taiwan-based Apus Molds and Plastics (AMP) says it has developed a ‘novel’ poly carbonate barrier system.

Made from PC and PP materials, the barrier is said to be long lasting and corrosion resistant, as well as being lightweight and quick to install. Impact performance is also said to be good as the material helps absorb shock.

AMP claims that the barrier has long life and is UV resistant, while they can also be recycled once they have reached the end of their design life. An array of colours are available to boost conspicuity, while lighting can also be fitted if required to further boost visibility or provide warnings to drivers.

The system is said to comply with Taiwan’s requirements for vehicle redirective capabilities and impact performance. The components are also said by AMP to be free from stress cracking problems and offer high stiffness, as well as being electrical insulators.

In standard applications, the barrier sections are fitted to round steel posts installed at 2metre intervals. The ductility of the nits is also said to allow them to be fitted on curves without the need for special modification.

Made from PC and PP materials, the barrier is said to be long lasting and corrosion resistant, as well as being lightweight and quick to install. Impact performance is also said to be good as the material helps absorb shock.

AMP claims that the barrier has long life and is UV resistant, while they can also be recycled once they have reached the end of their design life. An array of colours are available to boost conspicuity, while lighting can also be fitted if required to further boost visibility or provide warnings to drivers.

The system is said to comply with Taiwan’s requirements for vehicle redirective capabilities and impact performance. The components are also said by AMP to be free from stress cracking problems and offer high stiffness, as well as being electrical insulators.

In standard applications, the barrier sections are fitted to round steel posts installed at 2metre intervals. The ductility of the nits is also said to allow them to be fitted on curves without the need for special modification.