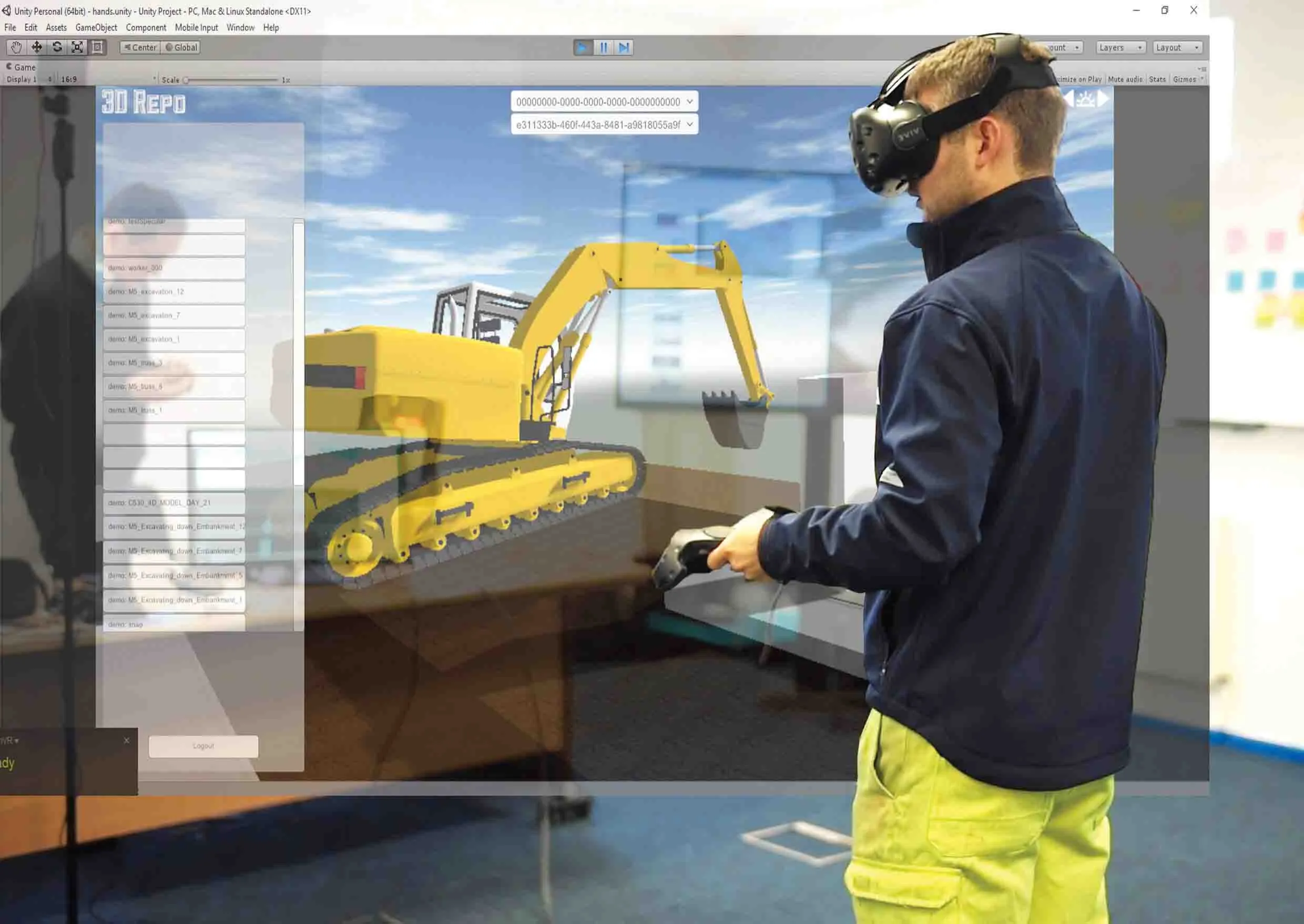

3D Repo, a spin-off from University College London, develops open-source software for building information modelling in the cloud. More than 40 different 3D file formats are decomposed and federated in the company’s big data repository.

The simulated program - part of the UK’s Smart Motorway programme – is a fully immersive simulation to prevent on-site accidents by making highways construction and maintenance projects safer through improved training. It features real world scenarios while the virtual experience gives users different perspectives of the same potentially dangerous situation in order to develop an understanding of safe working zones.

“In order to demonstrate our understanding of our customers’ needs and facilitate the collaboration between our customers and their clients, we wanted to digitally transform our approach,” commented

Neil Thompson, head of digital research at

All this is done within the safety of an office or training room and without the need for lengthy manuals, training sessions or specialist personnel. As the scenarios are hosted online, the system can be set up easily from any location and can be deployed across numerous sites at the same time.

“Upon login, users can access all their projects remotely on the fly and without the need to create custom executables each time,” said Jozef Dobos, chief executive of 3D Repo. “We also utilise existing site-specific 3D models and building information modelling (BIM) data so that custom scenarios can be created and uploaded as and when needed.”