The move stems from an agreement between the transport administrations in Sweden, Norway, Denmark and Iceland to establish a certification system suitable for the cold and harsh Nordic climate.

In Sweden, the certificates will be handled by NordicCert, a joint venture between engineering company

Trond Cato Johansen, project manager at Ramboll and head of NordicCert, said that about 530 materials are undergoing testing in Norway, Sweden and Denmark. NordicCert is also responsible for field-checkups to ensure that companies comply with certified material use.

Ennis Flint, Kestrel, Promax,

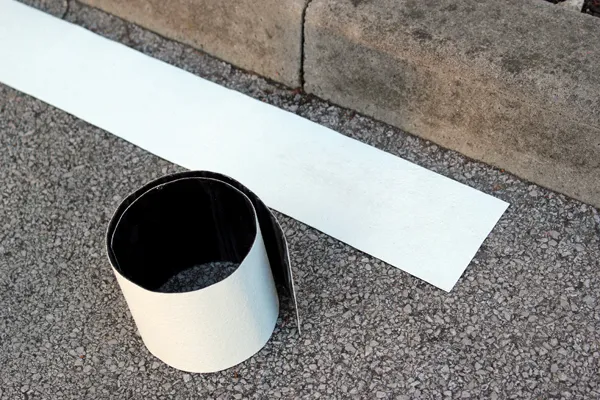

Product approval is based on monitored and documented performance measurements of material samples applied on test fields on public roads. Certification in Norway and Sweden is based on the results from a test site in Norway or in Sweden and certification in Denmark will be based on the results from a test site in Denmark. The first round of material tests in Sweden started in May 2015.

Performance parameters included the coefficient of retroreflected luminance (RL) under dry and wet conditions, the luminance coefficient under diffuse illumination (Qd), the friction, the chromaticity in daylight and the chromaticity of retroreflected light (yellow materials only).

The work of the certification group was published by the Swedish National Road and Transport Research Institute in early 2018.