The Faculty of Transport and Traffic Sciences, Department for Traffic Signalization, University of Zagreb has carried out extensive research into markings in partnership with SWARCO. The two bodies have evaluated the performance of waterborne and solvent based paints under normal usage conditions.

The aim is evaluate the use of waterborne road markings in Croatia, to reduce the emissions of volatile organic compounds and increase the safety of applicators by eliminating toxic and flammable materials. Te

April 29, 2015

Read time: 3 mins

The Faculty of Transport and Traffic Sciences, Department for Traffic Signalization, University of Zagreb has carried out extensive research into markings in partnership with SWARCO. The two bodies have evaluated the performance of waterborne and solvent based paints under normal usage conditions.

The aim is evaluate the use of waterborne road markings in Croatia, to reduce the emissions of volatile organic compounds and increase the safety of applicators by eliminating toxic and flammable materials. Testing of various glass beads classes and sizes to assess their performance in the applied waterborne materials has been carried out simultaneously. The research has also been intended to find the most effective paint for use in adverse conditions, to maximise safety. Until now, good wet weather performance has been achieved only with thick layer applications of cold- or thermo-plastic materials or with road marking tape.

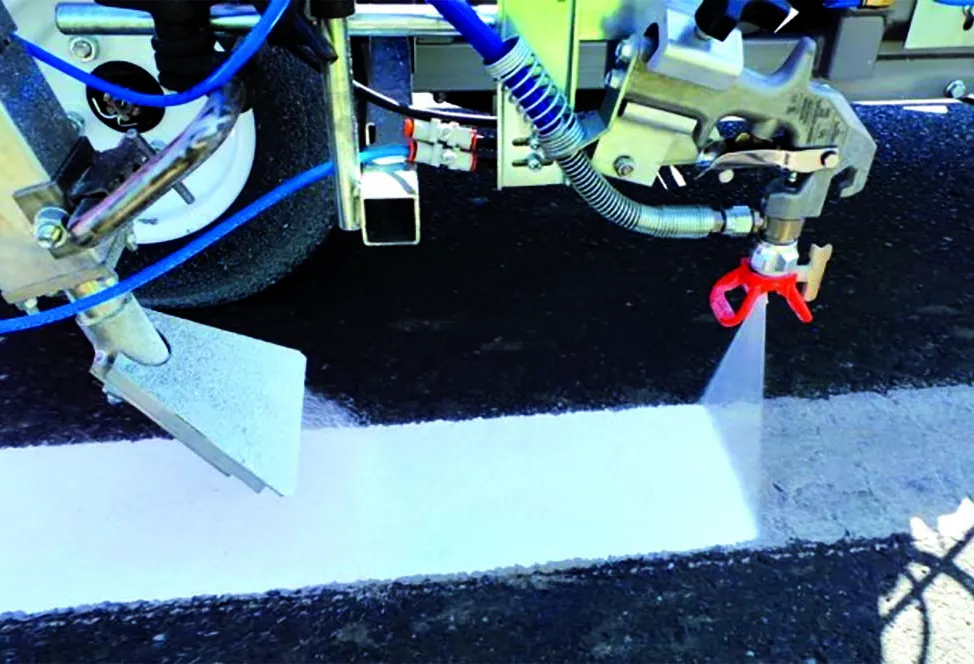

But two newly available waterborne paints (fast-dry Limboroute Aqua W13 and high-performance Limboroute Aqua W15 from337 SWARCO Limburger Lackfabrik) and standard high-solids solvent based paints have been evaluated. Glass beads of various sizes, provided by M Swarovski included SWARCO brands SolidPlus, Swarcolux, and Megalux-Beads. The application was carried out by local contractor Chemosignal on a road carrying around 8,000 vehicles/day.

In adverse weather conditions with high humidity and low temperatures, waterborne road marking paints dry slowly and require a long time to develop washout resistance.

However, if waterborne paints are applied during favourable weather, they dry faster than comparable solvent based products, helping to reduce traffic delays caused by work and boosting productivity.

For the good application conditions present during this work, the fast-dry paint W13 achieved washout resistance within 10 minutes — for comparison, simultaneously applied solvent based paints required about 15 minutes to dry.

For the application crew who were unfamiliar with waterborne road markings, the paints were easy to apply, even though adjustments to the application equipment were needed. Initial retroreflectivity measurements done by FPZ showed strong correlation with the glass beads used.

Retroreflectivity measurements from dynamic testing is processed using an FPZ-proprietary software and database. Periodic measurements of almost all of the main roads in Croatia (around 8,150km annually) are requested by local authorities and the results are shared online with contractors. The software developed at the University permits monitoring of the markings, application quality, and quick identification of problem areas.

The aim is evaluate the use of waterborne road markings in Croatia, to reduce the emissions of volatile organic compounds and increase the safety of applicators by eliminating toxic and flammable materials. Testing of various glass beads classes and sizes to assess their performance in the applied waterborne materials has been carried out simultaneously. The research has also been intended to find the most effective paint for use in adverse conditions, to maximise safety. Until now, good wet weather performance has been achieved only with thick layer applications of cold- or thermo-plastic materials or with road marking tape.

But two newly available waterborne paints (fast-dry Limboroute Aqua W13 and high-performance Limboroute Aqua W15 from

In adverse weather conditions with high humidity and low temperatures, waterborne road marking paints dry slowly and require a long time to develop washout resistance.

However, if waterborne paints are applied during favourable weather, they dry faster than comparable solvent based products, helping to reduce traffic delays caused by work and boosting productivity.

For the good application conditions present during this work, the fast-dry paint W13 achieved washout resistance within 10 minutes — for comparison, simultaneously applied solvent based paints required about 15 minutes to dry.

For the application crew who were unfamiliar with waterborne road markings, the paints were easy to apply, even though adjustments to the application equipment were needed. Initial retroreflectivity measurements done by FPZ showed strong correlation with the glass beads used.

Retroreflectivity measurements from dynamic testing is processed using an FPZ-proprietary software and database. Periodic measurements of almost all of the main roads in Croatia (around 8,150km annually) are requested by local authorities and the results are shared online with contractors. The software developed at the University permits monitoring of the markings, application quality, and quick identification of problem areas.