Crews have been working flat out on the Alaskan Way Tunnel in Seattle to install and test thousands of components and 90 interconnected systems.The client,

STP said that testing could be complete by late September and the tunnel could open as soon as this fall after an approximate three-week viaduct closure to realign the SR 99 – called the Alaskan Way - into the new tunnel.

The project is called the Alaskan Way Viaduct Replacement Project after the section of SR 99 in Seattle called the Alaskan Way, a street running along the seafront. Part of the Alaskan Way is an ageing 3.2km viaduct – opened in 1953 - which is being replaced by the 2.7km tunnel almost directly beneath it. This will free up waterfront area for major inner city development (see World Highways, Key Project Report, November 2017).

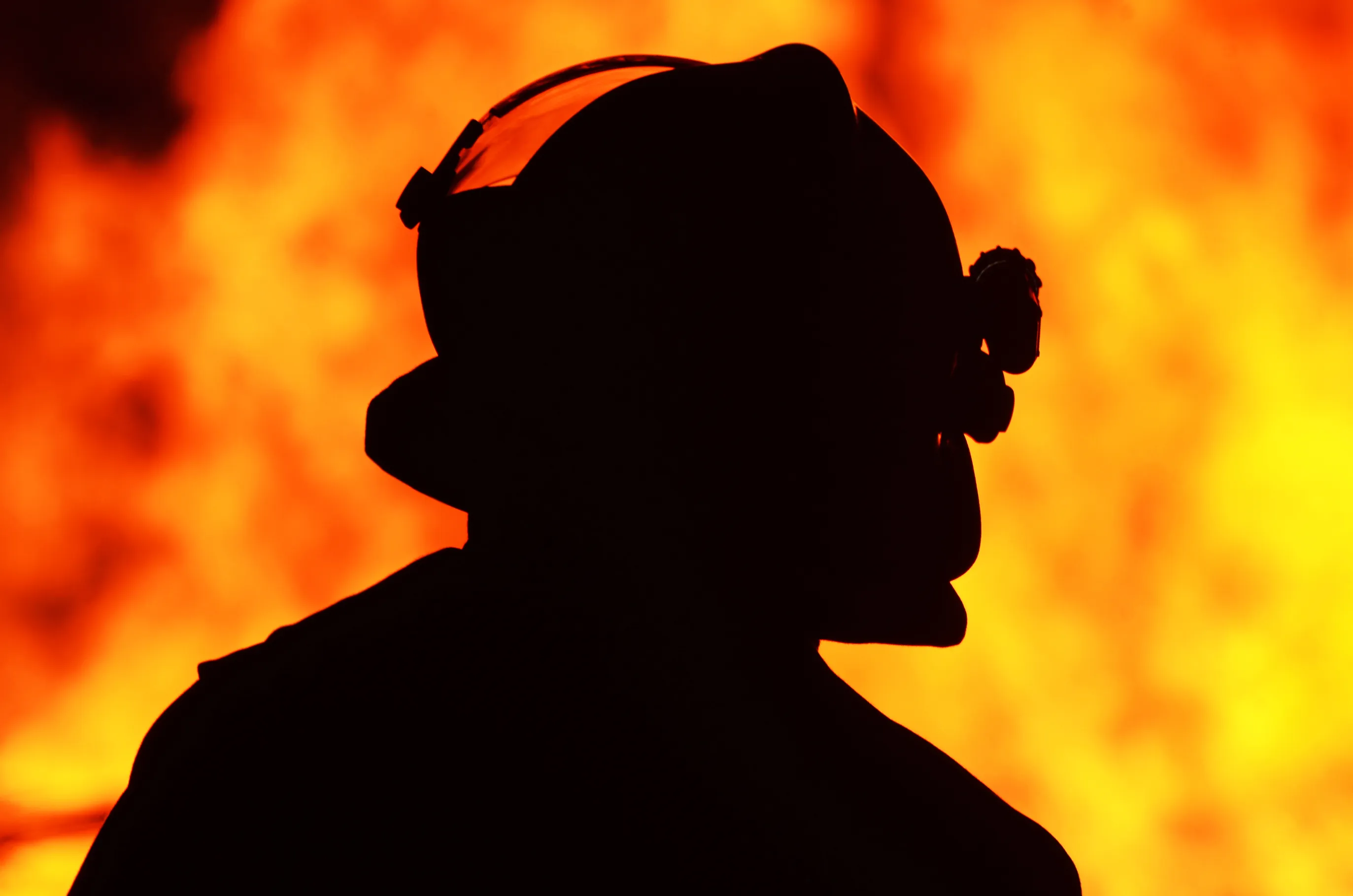

The multi-layered tests of the tunnel's operational and safety systems includes pre-functional tests to ensure working of individual equipment such as a sprinkler head. Functional tests check that the equipment works together as a system, for example multiple sprinklers. Finally, integrated testing checks that multiple systems function together - heat detectors and video cameras operate with the fire suppression system.

Striping of the road decks inside the tunnel is also continuing. The stripes separate a deck into two 3.3m lanes, a 2.4m shoulder on the left side and a 0.6m buffer on the right.

Kiewit Infrastructure West has started traffic signal, striping and roadway signage work to switch traffic on Alaskan Way from under the viaduct to the west of it. The viaduct will eventually be demolished after the tunnel is opened, likely this fall.

Tunnel boring was completed last year by Bertha, the world’s largest diameter earth pressure balance tunnel boring machine at the time, with a cutterhead diameter of 17.5m. By the end of last year it had been dismantled, job completed.

Seattle Tunnel Partners is a joint venture of New York-based

Apart from designing and building the tunnel - and owning Bertha - STP is responsible for building highway ramps and other connections at the north and south ends of the tunnel. STP is also constructing permanent buildings at the north and south portal to house lighting, ventilation and other essential tunnel systems.