Road markings and raised pavements markers (RPMs) are important tools in securing efficient and safe traffic flow, and the high visibility of both is an important task in road maintenance, says DELTA.

February 9, 2012

Read time: 3 mins

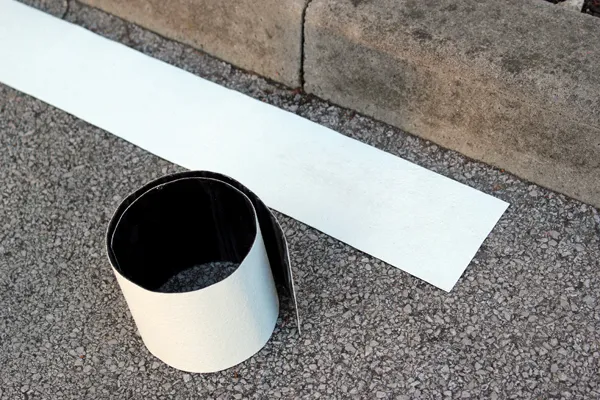

Road markings and raised pavements markers (RPMs) are important tools in securing efficient and safe traffic flow, and the high visibility of both is an important task in road maintenance, says DELTA.

Visibility is characterised by the optical retroreflection properties of both, and until now measurements of retroreflection have mostly been done with hand-held instruments such as the LTL-X produced by the Danish company.Although accurate and easy to use for making a limited number of measurements they are not optimal for monitoring long distances such as motorways. Retroreflection can vary even on short distances, such as in curves, where visibility is important, and as traffic increases there is a growing demand for mobile measurement systems that can monitor the retroreflection at normal traffic speeds.

According to

"The limited accuracy of existing mobile retrometers is mainly caused by vehicle movements, changes of wind and car load relative to the road surface. This movement changes the measurements' geometry and causes inaccurate readings. In order to increase the accuracy, frequent adjustments and checking of the systems are demanded, which limits the miles measured per day and also requires highly skilled personnel," says DELTA.

"For this reason, mobile retrometers have until now only been used for screening purposes and hand-held instruments are still needed for precise measurements if low values are screened and for contractual disputes and planning of maintenance." DELTA is now introducing a new generation of mobile retroreflectometers, the LTL-M, based on state-of-the-art-technology, which in addition to being as accurate as hand-held retrometers, is easy to install and operate, and can measure RPMs.

The new mobile instrument is based on a high-speed pulsating light source, fast digital camera technology and digital image processing, and the system is shown to have an accuracy comparable to hand-held instruments (+/-5% deviation).

"Several laboratory and field tests performed by the Swedish Road Research Institute (VTI) comparing the LTL-M, an existing mobile retroreflectometer and using a hand-held instrument as a reference, has shown that the LTL-M measures with an accuracy similar to hand-held instruments." [VTI report 675A: Evaluations of LTL-M at www.roadsensors.com].

The DELTA system measures the detailed cross-sectional retroreflection of the markings (many markings have strong transversal variation so a reading taken by a hand-held instruments with a 4-5cm wide measurement field in the centre does not represent the true visibility).

"The LTL-M gives a detailed analysis of the variation that can be correlated to both the true visibility as the driver sees the marking or to a middle section for correlation to a hand-held instrument.

"The systems measures white and yellow markings without the need for any recalibration; profiled markings up to 15mm profile depth; the daylight contrast between the road surface and the road marking; the geometry of the road marking including width and gaps in broken lines and damaged lines; one or two lines (for example double centre lines) simultaneously, and the transverse off-set on a restriped marking." It can also detect missing or non-working RPMs used separately or in combination with road markings, while the systems are easily calibrated in the field and can be integrated in existing road monitoring vehicles or standard cars.

The measurements data from the LTL-M are exported to GIS systems for mapping the markings and RPM properties.