Switzerland will soon tender for companies to build and supply a mobile system for physically shifting traffic away from bridge and road maintenance crews.

The federal highways agency - FEDRO - will be asking manufacturers of heavy equipment to submit bids starting this summer for the Astra Bridge system.

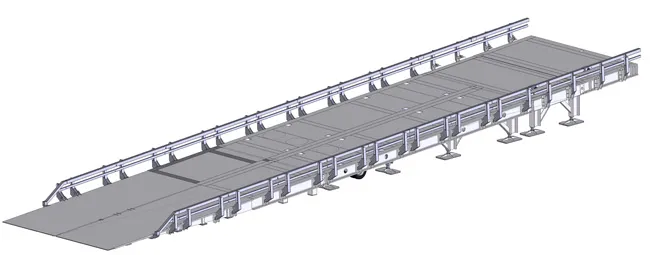

The system will be two lanes wide and include ramp sections at each end of what amounts to a train of elevated connected road sections – a modular construction. Vehicles run onto the top of the train which is positioned directly above where road crews are working. The effect is to create a “bridge” along the length of the lane below and under which paving or maintenance is safely underway and away from traffic.

“The inspiration for the Astra Bridge came with our work using a flyover ramp on bridges,” explained Ivo von Arx, a team leader with responsibility for bringing the project from the drawing board to reality. “It’s a pretty cool design,” he told World Highways. “As far as we know, there has never been anything like this before. We have also applied for a patent to the United Nation’s World Intellectual Property Organisation.”

In order to repair and maintain the heavily used motorways in metropolitan regions, work has to be carried out at night to an ever-increasing extent. The driving force for development of the Astra concept is that closures of traffic lanes for maintenance causes congestion - even during the night. To prevent this, maintenance times are periodically revised and frequently must be shortened which often affect a project’s schedule.

NUMBER OF TRAFFIC LANES: 2

LENGTH: 238m, but extendable using modular sections

WIDTH: 7.3m

MAXIMUM INCLINE (DRIVE-ON/DRIVE-OFF SECTIONS): 6.1%

CLEARANCE IN TRAVEL DIRECTION: 5.2m x 3.1m

LATERAL CLEARANCE: 2.2m x 3.1m

WEIGHT: around 1,200tonnes

MOVING SPEED: around 0.5kph

VEHICLE SPEED: 60kph

In addition, installation and removal of temporary worker safety barriers essential for night-time maintenance costs valuable time and money, noted FEDRO.

The call for tenders will encompass final design work, production of the system and quality control, assembly and dismantling processes and proper and safe operation of the completed assembly.

The chosen manufacturing company will be licenced by FEDRO to construct a system which will be owned by FEDRO and rented out to contractors that win maintenance work, said von Arx. Because FEDRO will own the copyright to the system, it could be that construction of other Astra Bridge systems globally will be licenced.

As well as moving the Astra Bridge lengthwise along the road, it can be shifted sideways if necessary to cover a third or third and fourth lanes, said von Arx. To avoid indentations in the road surface, the loads can be borne by large insulated base plates.

Moving the system over a distance of 100m should take between 10-20 minutes, according to the agency. It must be possible to assemble the drive-on and drive-off sections in the course of one night. The remainder of the bridge can be extended during a second night to a length of 238m.

Vehicle speed, including that for heavy goods vehicles, will be 60kph. A vehicle weight limit of 100tonnes is likely, meaning extra-wide or heavy loads will be banned from using the Astra, he said.

A maintenance site around 5.2m wide and 100m long can be set up beneath the Astra which can be raised hydraulically. FEDRO has also canvassed its maintenance crews about working beneath a structure such as the Astra Bridge. “They already have a lot of experience working beneath flyovers and they don’t see there will be a problem. Workers already wear suitable ear protection under flyovers.”

von Arx said the likely cost to construct the first Astra Bridge is not being disclosed as it will be determined in cooperation with the tender winner. However, it will probably be in the “millions of Swiss francs”.

FEDRO says it wants the system to be operational by 2022.