Engineers with RMD Kwikform used 3D modelling to overcome challenging terrain and tight schedules for pouring a single-deck concrete viaduct in mid-Norway. The Doro Viaduct is a post-tension three-span single-carriageway measuring 9.5m wide. It forms an important part of the large realignment of the E39 Harangen-Høgkjølen route in the Trondheim mid-region of Norway. The project needed a formwork and shoring solution to support a 93m-long, 750m3 single-deck pour for the three span Doro viaduct in Norway. For

March 13, 2015

Read time: 4 mins

Engineers with RMD Kwikform used 3D modelling to overcome challenging terrain and tight schedules for pouring a single-deck concrete viaduct in mid-Norway.

The Doro Viaduct is a post-tension three-span single-carriageway measuring 9.5m wide. It forms an important part of the large realignment of the E39 Harangen-Høgkjølen route in the Trondheim mid-region of Norway.

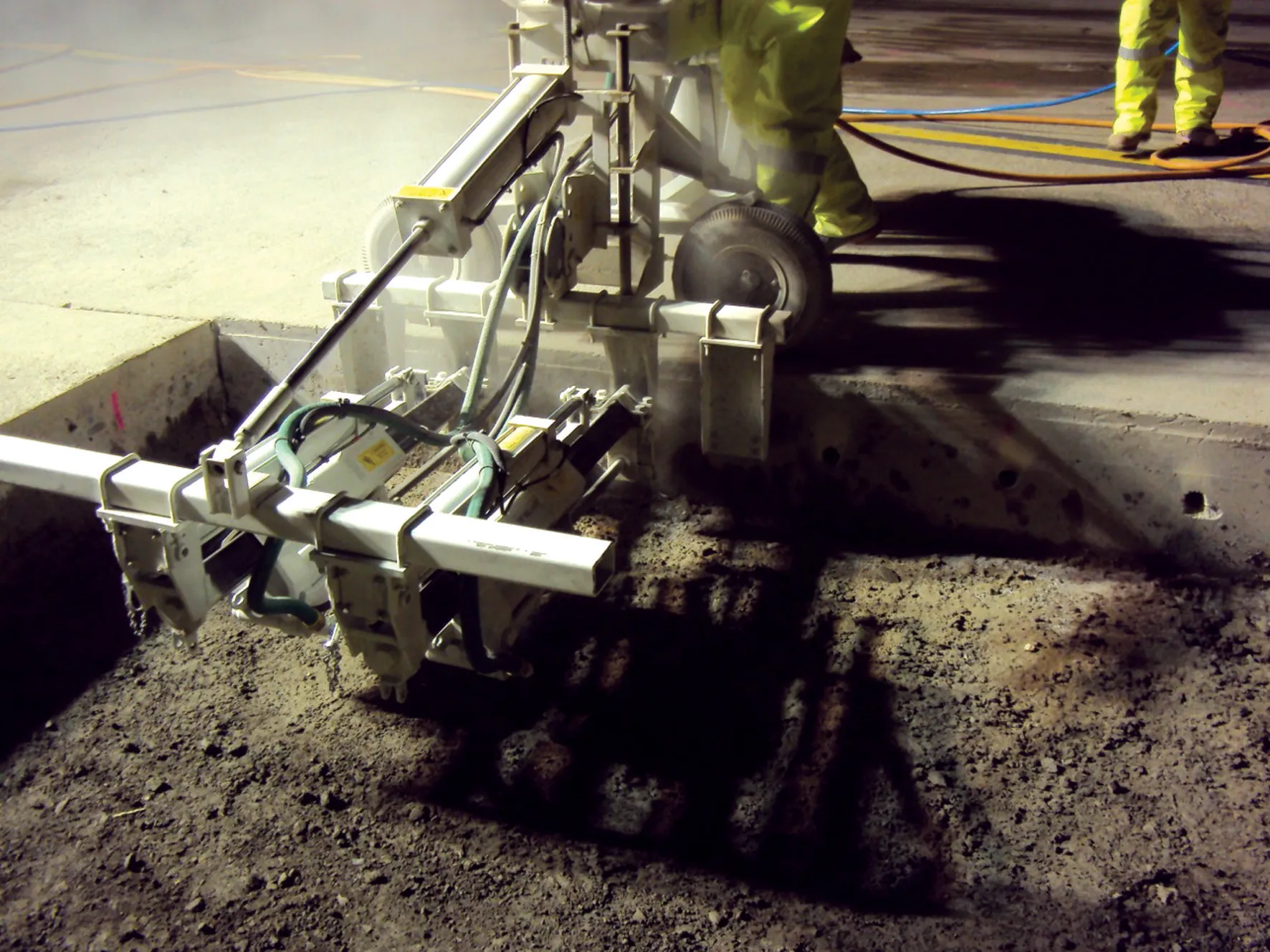

The project needed a formwork and shoring solution to support a 93m-long, 750m3 single-deck pour for the three span Doro viaduct in Norway.

Formwork and shoring for the project was supplied to specialist concrete contractor Sobstad by local formwork equipment supplier Hansmark, which has completed several other smaller projects for Kwikform.

The Kwikform engineering team was able to combine existing stocks of Rapidshor shoring and Superslim soldiers with their heavy duty Megashor shoring and R700 trusses for a complete viaduct solution.

But the pressure was on Sobstad to complete the single pour during August. Before this, Kwikform also had to work fast and ensure the right amount of equipment was shipped to the site for the start of erection work in March.

To assure the project went smoothly and efficiently, a 3D CAD model of the viaduct was created using information received from the site. This enabled production of detailed design drawings that in turn allowed accurate erection of the equipment and automatic equipment take-offs.

Three spans, measuring 29m, 35m and 29m requiring shoring support above the river running below in the Doro valley. Fortunately, the narrow width of the river meant only a clear span falsework solution was needed for one of the three viaduct spans.

To support this first 29m span, Kwikform designed a clear-span solution using five pairs of 25m-long R700 trusses, each weighing 11tonnes. One end of the trusses was supported by a six-legged Megashor tower mounted on the pier base with the other end sitting on a foundation near the abutment. Loadings from the trusses were transferred to the Megashor tower by an 11.5m-long header beam supporter by three 3m distribution beams.

The five R700 trusses were then craned into position and then steel Superslim soldiers were mounted on top of the trusses. A partial access platform was installed on top of the trusses to allow for the installation of a Rapidshor steel shoring birdcage arrangement, around 3.5m tall. By combining Rapidshor U heads at the base and top of the legs with bracing supports, the birdcage-style shoring structure was able to support another layer of Superslim soldier beams and timber secondary beams for the bridge deck soffit.

Because of the additional second and third spans supported by Rapidshor birdcage arrangements from the ground, varying in height from 8-14m, the viaduct with its 4.2% deck incline could be cast in one continuous pour.

“The whole site was very exposed and so the solution needed to support not only the loadings pressures from the single concrete pour, but to be robust enough to cope with high winds,” said Odd Inge Fremo, manager of the Trondheim area office of Hansmark.

“With the truss arrangement we wanted to minimise the amount of equipment needed onsite, yet be able to preassemble units next to the structure. With the Megashor tower we could lift sections into place, sequencing the build and similarly, because the R700 trusses were kept under the capacity of our site crane, we were able to simply manoeuvre them into place with minimal effort.”

He said that by using guide plates on the main header beam, when it came to extraction, the site team were able to simply move the trusses to one side, swinging them out safely using the crane. This saved both time and money.

Apart from supplying the equipment for the single deck pour,319 RMD Kwikform also engineered Rapidshor access towers used to construct bridge piers that would eventually support the viaduct.

RMD Kwikform had, prior to the Doro project, supplied Hansmark with Rapidshor solutions for the construction of the smaller Hallstein and Graven bridges on the same highway improvement programme.

The Doro Viaduct is a post-tension three-span single-carriageway measuring 9.5m wide. It forms an important part of the large realignment of the E39 Harangen-Høgkjølen route in the Trondheim mid-region of Norway.

The project needed a formwork and shoring solution to support a 93m-long, 750m3 single-deck pour for the three span Doro viaduct in Norway.

Formwork and shoring for the project was supplied to specialist concrete contractor Sobstad by local formwork equipment supplier Hansmark, which has completed several other smaller projects for Kwikform.

The Kwikform engineering team was able to combine existing stocks of Rapidshor shoring and Superslim soldiers with their heavy duty Megashor shoring and R700 trusses for a complete viaduct solution.

But the pressure was on Sobstad to complete the single pour during August. Before this, Kwikform also had to work fast and ensure the right amount of equipment was shipped to the site for the start of erection work in March.

To assure the project went smoothly and efficiently, a 3D CAD model of the viaduct was created using information received from the site. This enabled production of detailed design drawings that in turn allowed accurate erection of the equipment and automatic equipment take-offs.

Three spans, measuring 29m, 35m and 29m requiring shoring support above the river running below in the Doro valley. Fortunately, the narrow width of the river meant only a clear span falsework solution was needed for one of the three viaduct spans.

To support this first 29m span, Kwikform designed a clear-span solution using five pairs of 25m-long R700 trusses, each weighing 11tonnes. One end of the trusses was supported by a six-legged Megashor tower mounted on the pier base with the other end sitting on a foundation near the abutment. Loadings from the trusses were transferred to the Megashor tower by an 11.5m-long header beam supporter by three 3m distribution beams.

The five R700 trusses were then craned into position and then steel Superslim soldiers were mounted on top of the trusses. A partial access platform was installed on top of the trusses to allow for the installation of a Rapidshor steel shoring birdcage arrangement, around 3.5m tall. By combining Rapidshor U heads at the base and top of the legs with bracing supports, the birdcage-style shoring structure was able to support another layer of Superslim soldier beams and timber secondary beams for the bridge deck soffit.

Because of the additional second and third spans supported by Rapidshor birdcage arrangements from the ground, varying in height from 8-14m, the viaduct with its 4.2% deck incline could be cast in one continuous pour.

“The whole site was very exposed and so the solution needed to support not only the loadings pressures from the single concrete pour, but to be robust enough to cope with high winds,” said Odd Inge Fremo, manager of the Trondheim area office of Hansmark.

“With the truss arrangement we wanted to minimise the amount of equipment needed onsite, yet be able to preassemble units next to the structure. With the Megashor tower we could lift sections into place, sequencing the build and similarly, because the R700 trusses were kept under the capacity of our site crane, we were able to simply manoeuvre them into place with minimal effort.”

He said that by using guide plates on the main header beam, when it came to extraction, the site team were able to simply move the trusses to one side, swinging them out safely using the crane. This saved both time and money.

Apart from supplying the equipment for the single deck pour,

RMD Kwikform had, prior to the Doro project, supplied Hansmark with Rapidshor solutions for the construction of the smaller Hallstein and Graven bridges on the same highway improvement programme.