Much of the excavation work for the North Connex highway tunnel project in Sydney, Australia will be carried out by roadheaders from Sandvik. In all, six MT720s, one MT620 and six MT520 machines will work on the project, in addition to six road headers from other suppliers.

The work is being carried out by the Lend Lease–Bouygues Joint Venture (LLB JV) and is constructing a strategically important highway. The project is being sponsored by the NSW Government, Transurban and the M7 Westlink Shareholders.

November 20, 2015

Read time: 2 mins

Much of the excavation work for the North Connex highway tunnel project in Sydney, Australia will be carried out by roadheaders from 325 Sandvik. In all, six MT720s, one MT620 and six MT520 machines will work on the project, in addition to six road headers from other suppliers.

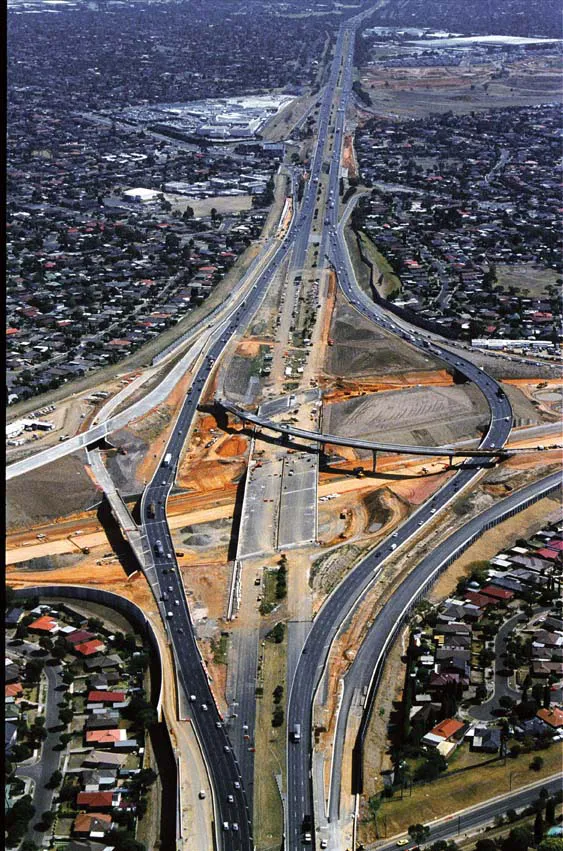

The work is being carried out by the Lend Lease–Bouygues Joint Venture (LLB JV) and is constructing a strategically important highway. The project is being sponsored by the NSW Government, Transurban and the M7 Westlink Shareholders. This tolled highway will connect the M1 Pacific Motorway at Wahroonga to the Hills M2 Motorway at West Pennant Hills – called North Connex. When complete, it will link Sydney's north to the Orbital network, and form part of the National Highway route. The scheme includes twin tunnels about 9km in length, with two lanes and a breakdown lane in each direction, as well as an increased height clearance of 5.3m with a speed limit of 80km/h. Each tunnel will be built with long-term capacity for three lanes, but will initially operate with two lanes and a breakdown lane in each direction.

The use of roadheaders was selected as the most suitable excavation method for North Connex. This was due to the large number of different tunnel profiles for intersections, ramps and shafts included in the project. Using a roadheader would allow the precise excavation profile required. The roadheaders chosen for the project are powered electro-hydraulically and are equipped with an advanced profile control, an automatic sequence control system and online data processing possibilities.

The work is being carried out by the Lend Lease–Bouygues Joint Venture (LLB JV) and is constructing a strategically important highway. The project is being sponsored by the NSW Government, Transurban and the M7 Westlink Shareholders. This tolled highway will connect the M1 Pacific Motorway at Wahroonga to the Hills M2 Motorway at West Pennant Hills – called North Connex. When complete, it will link Sydney's north to the Orbital network, and form part of the National Highway route. The scheme includes twin tunnels about 9km in length, with two lanes and a breakdown lane in each direction, as well as an increased height clearance of 5.3m with a speed limit of 80km/h. Each tunnel will be built with long-term capacity for three lanes, but will initially operate with two lanes and a breakdown lane in each direction.

The use of roadheaders was selected as the most suitable excavation method for North Connex. This was due to the large number of different tunnel profiles for intersections, ramps and shafts included in the project. Using a roadheader would allow the precise excavation profile required. The roadheaders chosen for the project are powered electro-hydraulically and are equipped with an advanced profile control, an automatic sequence control system and online data processing possibilities.