Trimble is now offering a dedicated, land-based 3D machine control system for use with a variety of piling machine makes and models. The DPS900 Piling System is said to boost accuracy and allows piling contractors to increase efficiency, taking over from less accurate manual alignment techniques that also take more time for set-up procedures and increase the risk of errors.

The firm says that the DPS900 system means contractors can take advantage of accurate positioning and automated reporting to ensure

October 1, 2014

Read time: 2 mins

The firm says that the DPS900 system means contractors can take advantage of accurate positioning and automated reporting to ensure machines are being used efficiently. The DPS900 Piling System reduces surveying costs associated with staking and as-built checks and can increase on-site safety by reducing the number of people around machines, pilings and foundations. Accurate positioning in DPS900 can ensure navigation time between piles is reduced, resulting in increased piling time to maximise production and revenue/day.

Built-in, automated quality assurance and quality control reporting includes capture of start and end positions, time and elevation as well as actual embedment depth, blow count reporting, and inclination and orientation control. In addition, unique system logins allow managers to filter reports by operator for better accountability, production optimisation and forecasting.

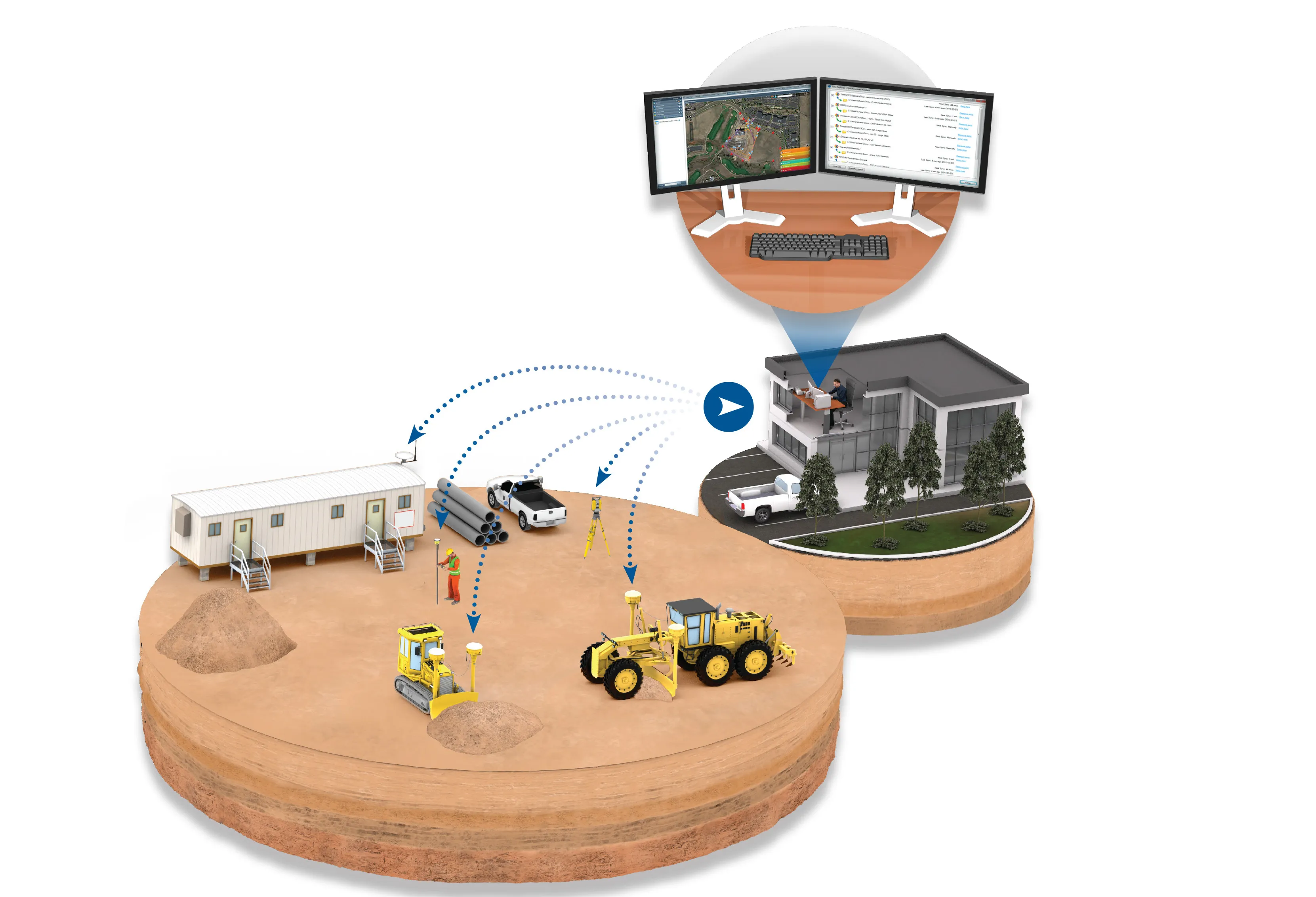

Business Center – HCE office software by Trimble is used to create pile plans in the office, and allows for integration with data preparation, estimating and reporting functions. Piling machines can be connected to the office using Trimble Connected Site solutions for wireless data transfer and GNSS corrections. In addition, machines can be tracked and monitored using VisionLink for location, hours and utilisation information.

The DPS900 Piling System is supported and serviced by a local SITECH technology dealer. The new Trimble DPS900 Piling System is available now in Australia, Europe, North America, Chile and South Africa through Trimble’s SITECH Technology Dealer Channel.