A UK highway project has benefited from the latest software, GIS and GPS technology, Mike Woof reports. Sophisticated software, GIS and GPS technology has played an important role in a large highway upgrade project in the UK and helping to increase efficiency and drive down construction costs.

February 16, 2012

Read time: 4 mins

A UK highway project has benefited from the latest software, GIS and GPS technology, Mike Woof reports

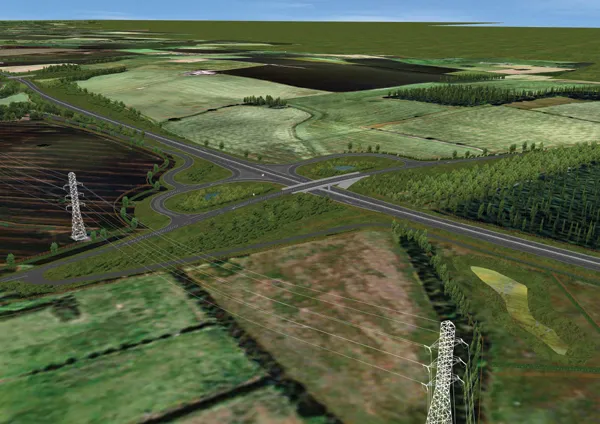

Sophisticated software, GIS and GPS technology has played an important role in a large highway upgrade project in the UK and helping to increase efficiency and drive down construction costs. Work on this highway project has used some of the most sophisticated tools available to the construction sector, speeding processes throughout, reducing construction delays and achieving better results in practically every stage. Employing advanced systems can result in faster delivery of a project, on time and within budget, while also eliminating many of the snags that can plague work using more conventional methods.The A46 Newark-Widmerpool upgrade is a e424 million (£360 million) project intended to increase capacity and boost safety by widening the link to two dual carriageway status with two lanes for traffic in either direction. The 28km road link carries a high volume of heavy goods vehicles and it was clear that the existing design, with a single lane in either direction, was not able to cope with demand or projected growth. The traffic load meant that safety standards were compromised, presenting a major concern. Carrying 25,000 vehicles/day, the existing A46 alignment was beyond its design capacity and this was highlighted by the fact that between 2001 and 2006 there were 13 fatal accidents on this section of road, making it clear to all that improvements were a necessity.

The design of the project has been handled by engineering firm URS/Scott Wilson (now part of the

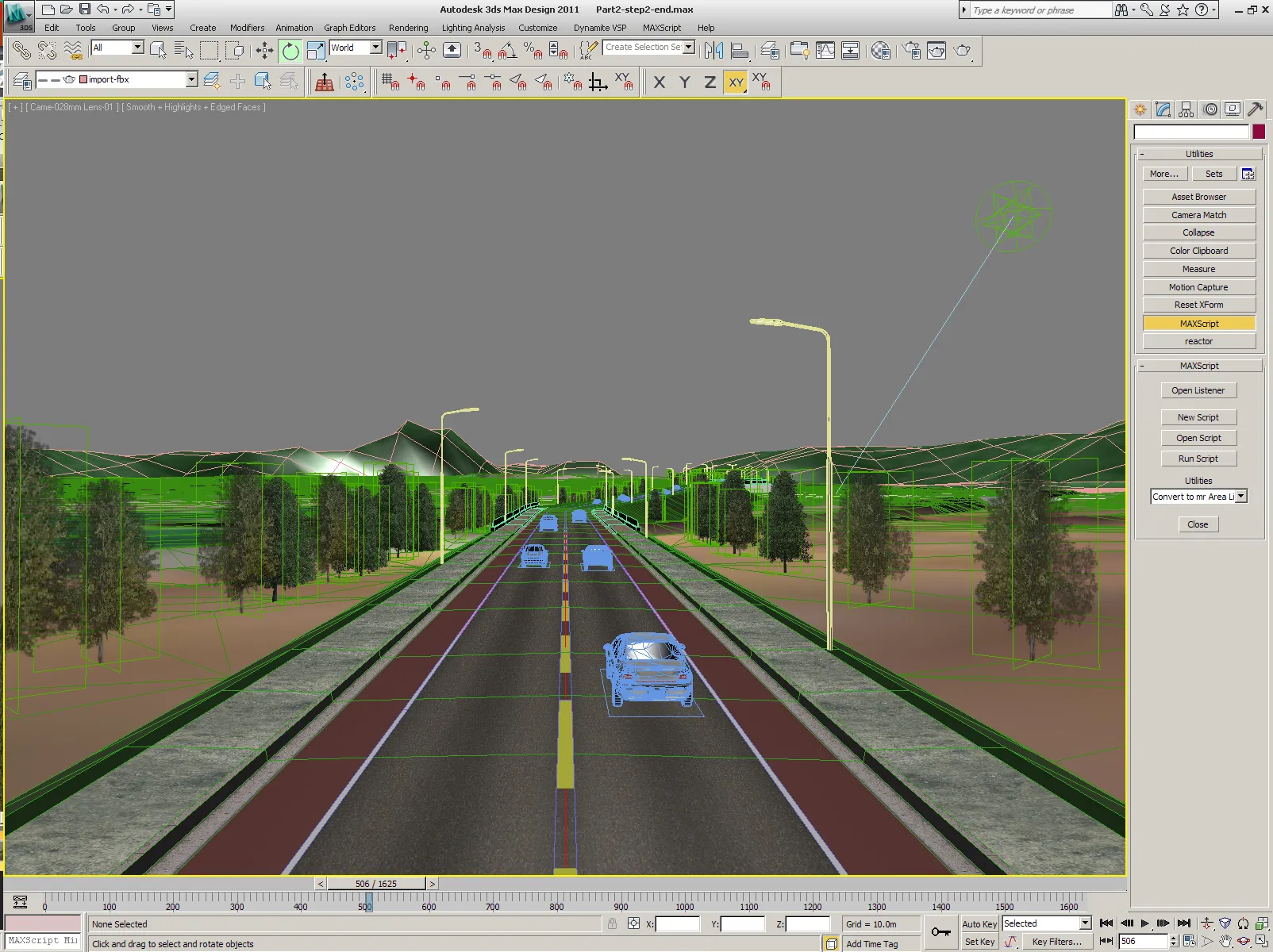

Using the software speeded the design process and allowed faster analysis of alternative features. One novel design feature that was evaluated for example was a special elliptical roundabout, although the team eventually opted for a more conventional round type. The software also helped during the public consultation phase as a dynamic 3D model was generated to bring the scheme to life and show the local authorities and other parties how the highway would look once complete. Wildgoose said, "It was successful in bringing the project to life." During the public consultation process, the ability to use the Bentley MX designs to show the highway route to local groups was extremely useful, according to Wildgoose. This facility convinced many doubters of the value of the upgrade and that it would be beneficial.

A detailed design was then carried out using clash detection techniques to highlight potential issues and this was used to realign drainage for example even before any work was carried out. The contractor, Balfour Beatty used sophisticated

A key factor of this process according to Wildgoose was that the Topcon, Bentley and Trimble software all worked efficiently. Despite the technology being from different suppliers (and in the case of Topcon and Trimble, competing firms), the data was collected, used and transferred from one package to another without any problems. "This was a seamless process to and from MX," Wildgoose said.

Direct cost benefits were achieved by the sophisticated design processes and the ability to transfer the Bentley model URS/Scott Wilson developed, directly into the 3D Trimble machine control tools fitted to the earthmoving equipment. Wildgoose said that this increased efficiency by allowing the earthmoving work to be carried out stakelessly to the specified design and within required tolerances, but without need for reworking. This stage alone saved some e2.35 million (£2 million) in earthmoving costs.

The project not only met the needs of the client, the Highways Agency, but was also sufficiently noteworthy to be selected as winner in the roads category of Bentley Software's Be Inspired conference in late 2010.