One of the most demanding and challenging impressed current cathodic protection (ICCP) projects ever undertaken by specialist main contractor Concrete Repairs Ltd (CRL) is being carried out on Bideford Longbridge in County Devon, UK. The 24-span medieval masonry arch bridge spans 190m over the tidal estuary of the River Torridge.

February 29, 2012

Read time: 2 mins

One of the most demanding and challenging impressed current cathodic protection (ICCP) projects ever undertaken by specialist main contractor 3416 Concrete Repairs Ltd (CRL) is being carried out on Bideford Longbridge in County Devon, UK.

The 24-span medieval masonry arch bridge spans 190m over the tidal estuary of the River Torridge. Each span varies from 6.5m to 11m, and this is thought to be because the masonry bridge was built around the original timber bridge whose spans were dictated by the length of timber available at the time. During its lifetime the bridge has been widened a number of times to accommodate the changing nature and density of traffic flows. The last widening was completed in 1928 when reinforced concrete cantilever sections were added to each side of the masonry arches.

Following a structural assessment in 2006, Devon County Council identified 21 weakened cantilevers and the onset of corroding steel reinforcement, caused as a result of high chloride levels and lack of concrete cover. A 3tonne weight restriction was applied while various long term renovation solutions to safeguard the bridge were considered.

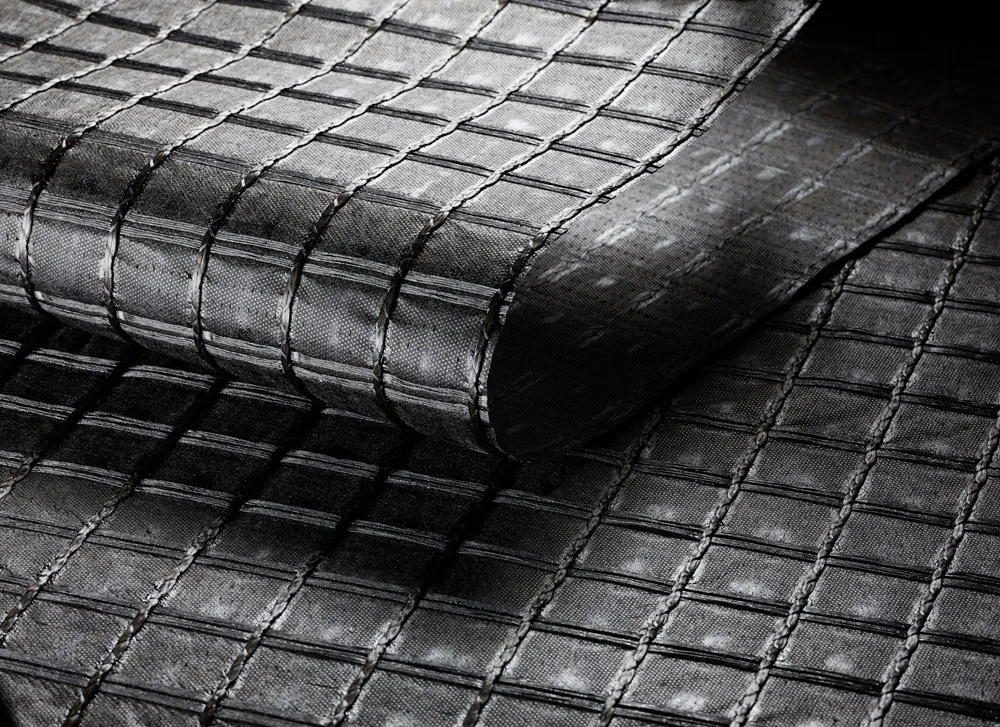

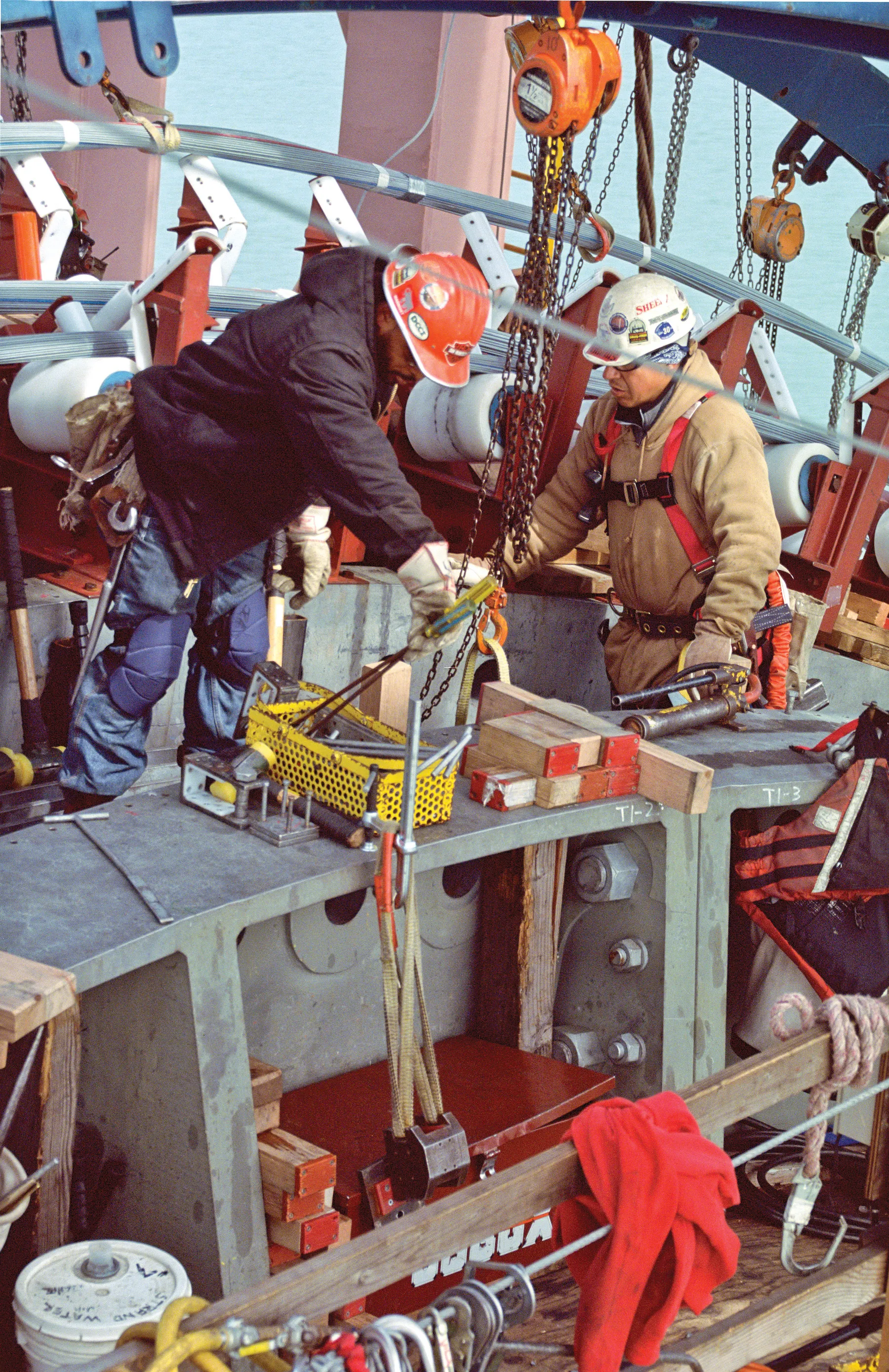

CRL was awarded the council contract to repair the concrete cantilevers in September 2008. The £2m project (E2.34 million) is particularly testing due to the combination of ICCP anode systems comprising mixed metal oxide coated titanium mesh and discrete mixed metal oxide coated titanium tubular anodes to ensure a uniform current distribution.

At the same time, the partial demolition and reconstruction of reinforced concrete elements is being carried out and a new underbridge lighting system is being installed, all of which is taking place from restricted scaffold access and in a tidal environment. The project is scheduled for completion in October 2009.

The 24-span medieval masonry arch bridge spans 190m over the tidal estuary of the River Torridge. Each span varies from 6.5m to 11m, and this is thought to be because the masonry bridge was built around the original timber bridge whose spans were dictated by the length of timber available at the time. During its lifetime the bridge has been widened a number of times to accommodate the changing nature and density of traffic flows. The last widening was completed in 1928 when reinforced concrete cantilever sections were added to each side of the masonry arches.

Following a structural assessment in 2006, Devon County Council identified 21 weakened cantilevers and the onset of corroding steel reinforcement, caused as a result of high chloride levels and lack of concrete cover. A 3tonne weight restriction was applied while various long term renovation solutions to safeguard the bridge were considered.

CRL was awarded the council contract to repair the concrete cantilevers in September 2008. The £2m project (E2.34 million) is particularly testing due to the combination of ICCP anode systems comprising mixed metal oxide coated titanium mesh and discrete mixed metal oxide coated titanium tubular anodes to ensure a uniform current distribution.

At the same time, the partial demolition and reconstruction of reinforced concrete elements is being carried out and a new underbridge lighting system is being installed, all of which is taking place from restricted scaffold access and in a tidal environment. The project is scheduled for completion in October 2009.