Spanish company Ulma Construction said that is has developed Biramax in an effort to create adjustable formwork at once easy to assemble and profitable for the client, in terms of both use and durability.

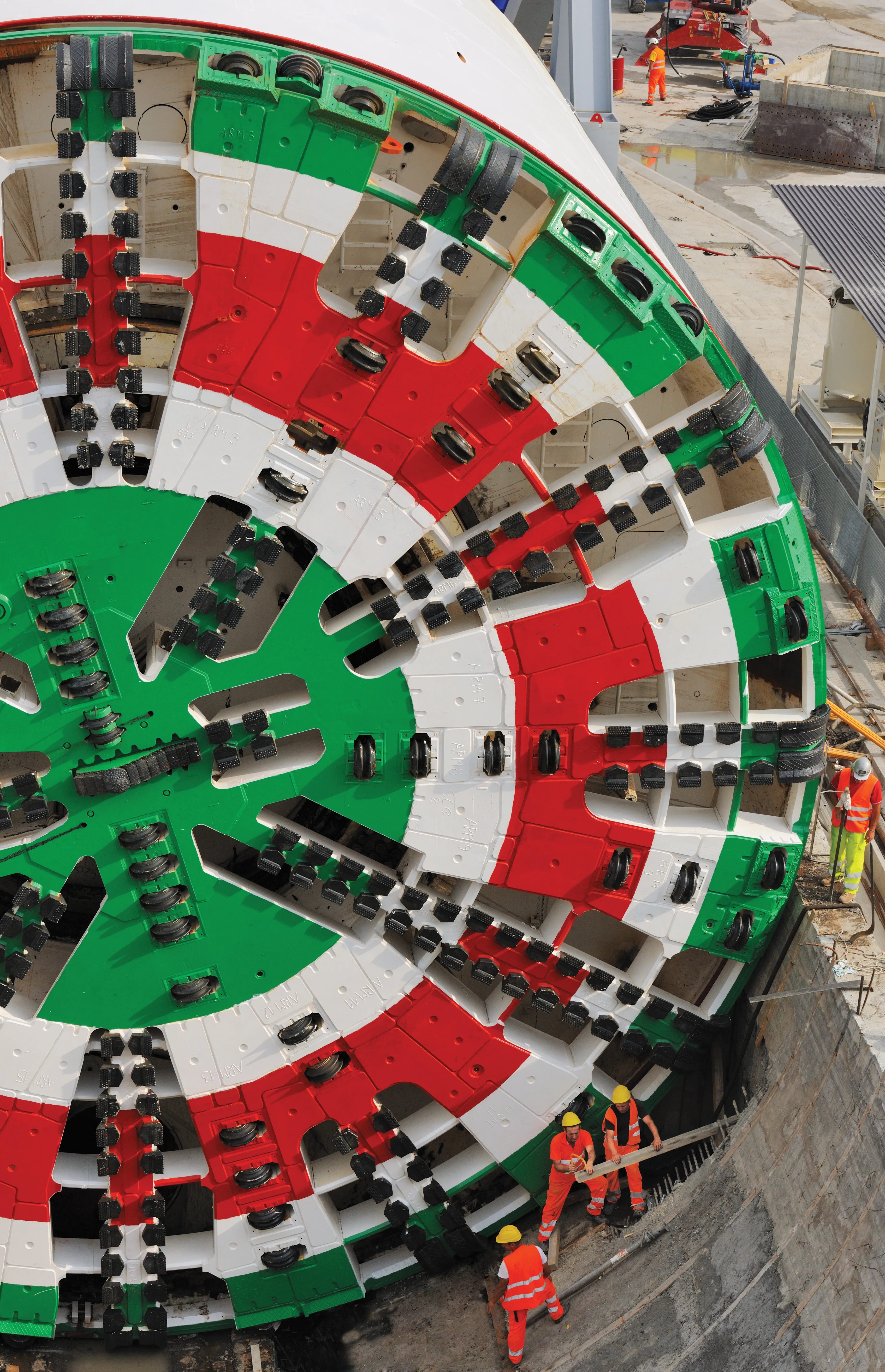

The adjustable circular formwork Biramax has only four adjustment points and the placement of compensation plates between panels is easy to accomplish.

The panel frame is made of the high-quality and resistant galvanised steel and the plastic surface of the formwork panels is highly moisture resista

October 28, 2016

Read time: 2 mins

Spanish company Ulma Construction said that is has developed Biramax in an effort to create adjustable formwork at once easy to assemble and profitable for the client, in terms of both use and durability.

The adjustable circular formwork Biramax has only four adjustment points and the placement of compensation plates between panels is easy to accomplish.

The panel frame is made of the high-quality and resistant galvanised steel and the plastic surface of the formwork panels is highly moisture resistant. Ulma says that this means it’s easy to maintain and repair and the plastic-coated plywood panels offers excellent concrete finishes.

Biramax formwork has a minimum curvature radius of 2m and is resistant to high concrete pressures, up to 80kN/m2. Various platforms are available that guarantee worker safety both during assembly of the system and concrete-pouring phases.

The development of Biramax has been possible through the company’s continuous programme of research and customer feedback that has focused on safety and efficiency for the work force that translates into profitability for its clients.

Ulma said that Biramax complements its ENKOFORM VMK and ENKOFORM V-100 timber beam formwork to shape any circular wall, whether it be of varied or fixed radius, for installations such as water tanks, storage areas and tunnels.

Ulma’s global projects include the El Salto Viaduct near Santiago, Chile, the bypass road and motorway in Port of El Salvador, Brazil, and the 34km motorway A4 and overpass E118 on the Tarnów – Dębica route in Poland.

The adjustable circular formwork Biramax has only four adjustment points and the placement of compensation plates between panels is easy to accomplish.

The panel frame is made of the high-quality and resistant galvanised steel and the plastic surface of the formwork panels is highly moisture resistant. Ulma says that this means it’s easy to maintain and repair and the plastic-coated plywood panels offers excellent concrete finishes.

Biramax formwork has a minimum curvature radius of 2m and is resistant to high concrete pressures, up to 80kN/m2. Various platforms are available that guarantee worker safety both during assembly of the system and concrete-pouring phases.

The development of Biramax has been possible through the company’s continuous programme of research and customer feedback that has focused on safety and efficiency for the work force that translates into profitability for its clients.

Ulma said that Biramax complements its ENKOFORM VMK and ENKOFORM V-100 timber beam formwork to shape any circular wall, whether it be of varied or fixed radius, for installations such as water tanks, storage areas and tunnels.

Ulma’s global projects include the El Salto Viaduct near Santiago, Chile, the bypass road and motorway in Port of El Salvador, Brazil, and the 34km motorway A4 and overpass E118 on the Tarnów – Dębica route in Poland.