Five buoy-mounted automatic water quality monitors (AWQMs) have been installed by YSI Hydrodata engineers at the new Tyne Tunnel project in north-east England. The equipment on the second vehicle tunnel under the River Tyne, currently one of the UK's largest construction projects, aims to ensure that construction operations do not significantly affect river water quality. Unusually, the contractors have not taken ownership of the instrumentation, preferring instead to simply purchase the data and alarms. Th

February 6, 2012

Read time: 4 mins

Five buoy-mounted automatic water quality monitors (AWQMs) have been installed by 2324 YSI Hydrodata engineers at the new Tyne Tunnel project in north-east England.

The equipment on the second vehicle tunnel under the River Tyne, currently one of the UK's largest construction projects, aims to ensure that construction operations do not significantly affect river water quality. Unusually, the contractors have not taken ownership of the instrumentation, preferring instead to simply purchase the data and alarms.

The new tunnel is scheduled to open in February next year when the existing tunnel will close for refurbishment. TT2, the Tyne Tunnel concessionaire, expects both tunnels to be fully operational by 2012, bringing incredible reductions in journey times for customers.

In 1967 a two-lane toll vehicular tunnel was built under the River Tyne a few kilometres east of the city of Newcastle upon Tyne. Originally designed for a daily traffic throughput of 24,000 vehicles, it now carries 38,000 customers per day.

In July 2005, approval was given to the Tyne & Wear Passenger Transport Authority (now the1436 Tyne and Wear Integrated Transport Authority/TWITA) for a new tunnel, and construction started in spring 2008.

The new tunnel has been constructed utilising a hybrid method: immersed tubes form the river section and a cut-and-cover method has been deployed on the landside. The river section involved the construction of four 90m long, 15m wide and 8.5m high concrete units in the nearby Walker Dry Dock, and these were subsequently floated down river and lowered into position.

The riverbed location for the concrete cylinders forming the tunnel was formed by a 'cutter suction dredger' capable of pumping up to 7,000m3 of sediment/water slurry per hour. In total, the dredger removed 400,000m3 of sediment over a five-week period during December 2009.

YSI Hydrodata was contracted to provide continuous monitoring data from five locations in the river. They did this by setting up a website accessible to the key stakeholders (Newcastle University, Newcastle City Council, the contractor Bouygues Travaux Publics, the dredging company Jan De Nul, Port of Tyne and the Environment Agency) to whom the data was transmitted in real-time.

The Environment Agency reached a legal agreement with TWITA that included water quality standards to ensure the protection of the environment and particularly migrating salmon on their way to breed in the upper Tyne catchment.

The AWQMs were installed around 12 months prior to the start of dredging operations so that normal water quality conditions could be established.

The standards were based on differences between measurements of water quality upstream and downstream (depending on the tide) of the dredging operations. This allowed the impact of the dredging operation to be distinguished from background variations.

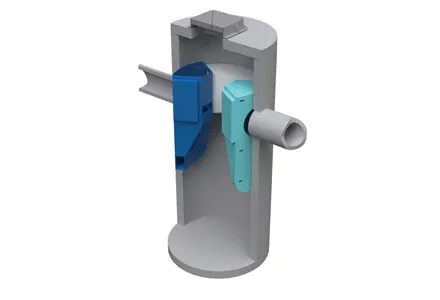

Roger Inverarity, a water quality planner with the Environment Agency says: "Having access to continuous live water quality data via a website gave all stakeholders information about what was happening in the river, day or night. It enabled the dredger to respond to any deterioration and us, the regulator, to check that they were doing so." Each of the YSI AWQMs is fitted with highly accurate sensors that are designed to operate in challenging environments. These continuously measure dissolved oxygen, turbidity and temperature in addition to velocity.

The AWQMS raised alarms on a small number of occasions, largely as a result of high turbidity in the overflow from the dock. When alarm conditions arose, an email was automatically generated with a copy going to a mobile phone on the dredger, and dredging ceased until water quality had returned to acceptable levels.

YSI Hydrodata's Andy Burton was responsible for the installation and maintenance of the AWQMs. "Monitoring water quality in a tidal estuary close to the North Sea in all weathers has been a significant challenge and the reliability of our data is testament to the ruggedness of the instruments. Our anti-fouling technology proved to be a particular benefit in these aggressive conditions," he says.

Nicolas Caille, project managing director for Bouygues Travaux Publics UK, says: "We were very pleased with the outcome of the dredging works. The water quality monitoring demonstrated that we delivered this sensitive aspect of the works with the highest regard for environmental protection. The choice of monitoring equipment was important because we had to satisfy environmental stakeholders in terms of reliability, sensitivity, and accuracy. The technology we opted for provided great reassurance to all parties."

The equipment on the second vehicle tunnel under the River Tyne, currently one of the UK's largest construction projects, aims to ensure that construction operations do not significantly affect river water quality. Unusually, the contractors have not taken ownership of the instrumentation, preferring instead to simply purchase the data and alarms.

The new tunnel is scheduled to open in February next year when the existing tunnel will close for refurbishment. TT2, the Tyne Tunnel concessionaire, expects both tunnels to be fully operational by 2012, bringing incredible reductions in journey times for customers.

In 1967 a two-lane toll vehicular tunnel was built under the River Tyne a few kilometres east of the city of Newcastle upon Tyne. Originally designed for a daily traffic throughput of 24,000 vehicles, it now carries 38,000 customers per day.

In July 2005, approval was given to the Tyne & Wear Passenger Transport Authority (now the

The new tunnel has been constructed utilising a hybrid method: immersed tubes form the river section and a cut-and-cover method has been deployed on the landside. The river section involved the construction of four 90m long, 15m wide and 8.5m high concrete units in the nearby Walker Dry Dock, and these were subsequently floated down river and lowered into position.

The riverbed location for the concrete cylinders forming the tunnel was formed by a 'cutter suction dredger' capable of pumping up to 7,000m3 of sediment/water slurry per hour. In total, the dredger removed 400,000m3 of sediment over a five-week period during December 2009.

YSI Hydrodata was contracted to provide continuous monitoring data from five locations in the river. They did this by setting up a website accessible to the key stakeholders (Newcastle University, Newcastle City Council, the contractor Bouygues Travaux Publics, the dredging company Jan De Nul, Port of Tyne and the Environment Agency) to whom the data was transmitted in real-time.

The Environment Agency reached a legal agreement with TWITA that included water quality standards to ensure the protection of the environment and particularly migrating salmon on their way to breed in the upper Tyne catchment.

The AWQMs were installed around 12 months prior to the start of dredging operations so that normal water quality conditions could be established.

The standards were based on differences between measurements of water quality upstream and downstream (depending on the tide) of the dredging operations. This allowed the impact of the dredging operation to be distinguished from background variations.

Roger Inverarity, a water quality planner with the Environment Agency says: "Having access to continuous live water quality data via a website gave all stakeholders information about what was happening in the river, day or night. It enabled the dredger to respond to any deterioration and us, the regulator, to check that they were doing so." Each of the YSI AWQMs is fitted with highly accurate sensors that are designed to operate in challenging environments. These continuously measure dissolved oxygen, turbidity and temperature in addition to velocity.

The AWQMS raised alarms on a small number of occasions, largely as a result of high turbidity in the overflow from the dock. When alarm conditions arose, an email was automatically generated with a copy going to a mobile phone on the dredger, and dredging ceased until water quality had returned to acceptable levels.

YSI Hydrodata's Andy Burton was responsible for the installation and maintenance of the AWQMs. "Monitoring water quality in a tidal estuary close to the North Sea in all weathers has been a significant challenge and the reliability of our data is testament to the ruggedness of the instruments. Our anti-fouling technology proved to be a particular benefit in these aggressive conditions," he says.

Nicolas Caille, project managing director for Bouygues Travaux Publics UK, says: "We were very pleased with the outcome of the dredging works. The water quality monitoring demonstrated that we delivered this sensitive aspect of the works with the highest regard for environmental protection. The choice of monitoring equipment was important because we had to satisfy environmental stakeholders in terms of reliability, sensitivity, and accuracy. The technology we opted for provided great reassurance to all parties."