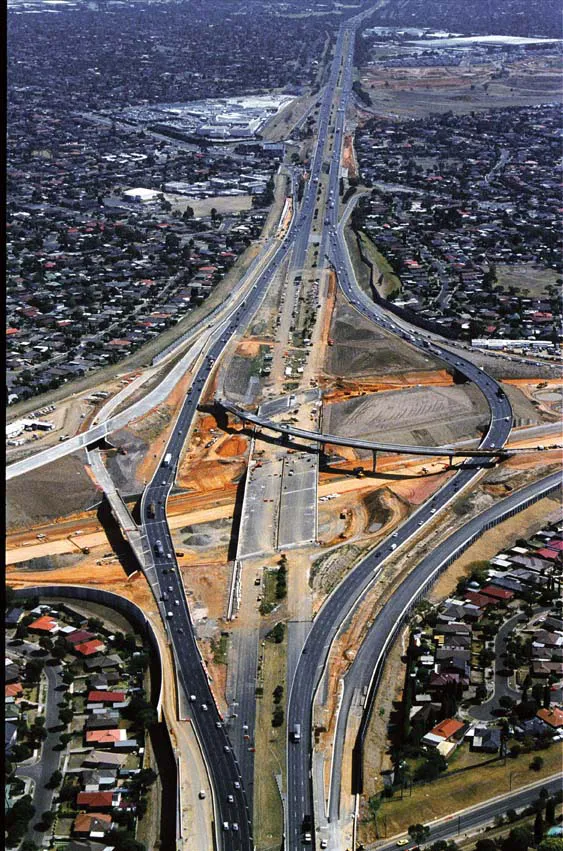

The Gold Coast region in the Australian state of Queensland is internationally renowned as a tourist area attracting thousands of visitors from Brisbane, where the state's biggest ever road and bridge upgrade project is currently underway. Some 12km of urban route on the south of the Brisbane River is being expanded to take much increased traffic levels: the north is getting a completely new 7km section of motorway on a different alignment to bypass extra traffic, and tolls are being automated to speed flow

July 16, 2012

Read time: 3 mins

The Gold Coast region in the Australian state of Queensland is internationally renowned as a tourist area attracting thousands of visitors from Brisbane, where the state's biggest ever road and bridge upgrade project is currently underway.

Some 12km of urban route on the south of the Brisbane River is being expanded to take much increased traffic levels: the north is getting a completely new 7km section of motorway on a different alignment to bypass extra traffic, and tolls are being automated to speed flows.

At the heart of the project is a duplication of the 1.63km long Gateway Bridge, with its slim central soaring concrete arch, which was a world record holder in its time for a concrete box balanced cantilever bridge. The 260m long main span carrying three lanes of traffic each way, nearly 65m above the river, is still the biggest hollow concrete box construction anywhere.

The AU$1.88 billion (US$1.5 billion) Brisbane Gateway Upgrade Project in the state capital will help alleviate traffic congestion in the area and improve the vital link to the Gold Coast.

"The upgrade project will deliver many benefits to Queensland, including safer, quicker and easier travel on the Gateway Motorway; better connections for business, industry and tourism, and an overall improved situation for motorists, cyclists and pedestrians," says Jeremy Shaw, Conplant client services manager, the Australian distributor of Ammann products (some 40 Ammann rollers are in use on the project), which hired out all the machines on the south side of the project.

"The majority of the rollers on this site are Ammann products, ranging from

1-27tonne vibrating smooth and pad drum rollers, and are equipped with ROPS2 anti-roll technology.

"Worksites on the south side feature some very steep batters and abutments, so the ROPS2 technology is an excellent safety net, particularly for less experienced operators. There is next to no possibility of a rollover as long as the operator is following proper procedure, and there have been no rollover incidents on this project."

ROPS2 is a two-stage system that first alerts the operator with an audible alarm when a pre-determined gradient is reached, then shuts down the vibration if the machine continues to tilt, and was introduced to the Australian market in 2007.

Some 12km of urban route on the south of the Brisbane River is being expanded to take much increased traffic levels: the north is getting a completely new 7km section of motorway on a different alignment to bypass extra traffic, and tolls are being automated to speed flows.

At the heart of the project is a duplication of the 1.63km long Gateway Bridge, with its slim central soaring concrete arch, which was a world record holder in its time for a concrete box balanced cantilever bridge. The 260m long main span carrying three lanes of traffic each way, nearly 65m above the river, is still the biggest hollow concrete box construction anywhere.

The AU$1.88 billion (US$1.5 billion) Brisbane Gateway Upgrade Project in the state capital will help alleviate traffic congestion in the area and improve the vital link to the Gold Coast.

"The upgrade project will deliver many benefits to Queensland, including safer, quicker and easier travel on the Gateway Motorway; better connections for business, industry and tourism, and an overall improved situation for motorists, cyclists and pedestrians," says Jeremy Shaw, Conplant client services manager, the Australian distributor of Ammann products (some 40 Ammann rollers are in use on the project), which hired out all the machines on the south side of the project.

"The majority of the rollers on this site are Ammann products, ranging from

1-27tonne vibrating smooth and pad drum rollers, and are equipped with ROPS2 anti-roll technology.

"Worksites on the south side feature some very steep batters and abutments, so the ROPS2 technology is an excellent safety net, particularly for less experienced operators. There is next to no possibility of a rollover as long as the operator is following proper procedure, and there have been no rollover incidents on this project."

ROPS2 is a two-stage system that first alerts the operator with an audible alarm when a pre-determined gradient is reached, then shuts down the vibration if the machine continues to tilt, and was introduced to the Australian market in 2007.