An innovative sustainable drainage material is said to offer a simple and versatile solution to removing toxic heavy metals pollution from highways.

Developed by the water infrastructure systems provider SDS Limited, SDS Aqua-Xchange is a versatile and efficient granular material that captures copper and zinc in surface water runoff from motorways, trunk roads and other high-traffic areas.

SDS Aqua-Xchange is an engineered treatment media that can be used to meet the UK’s Sustainable Drainage Systems (SuDS) requirements. It has been shown in independent testing to achieve 99% removal of dissolved copper and zinc, metals subject to strict regulatory controls.

Delivered to site in 1m3 bags, SDS Aqua-Xchange is available for consulting engineers and infrastructure contractors to deploy as stormwater treatment in highways drainage. It can also be used for high-risk locations such as retail car parks, freight and logistics hubs.

SDS worked with scientists at the University of Chester to develop SDS Aqua-Xchange. A combination of naturally-occurring materials, it uses the processes of adsorption and ionic exchange to form unbreakable bonds with the heavy metals, including copper and zinc, capturing and retaining them even in heavy storms.

The firm says that because of its granular composition, SDS Aqua-Xchange has a large active surface area, enabling high-performance pollutant removal in a small space. As a result, it can be used to deliver pretreatment as part of a vegetative SuDS scheme, enabling smaller SuDS ponds or wetlands to be designed.

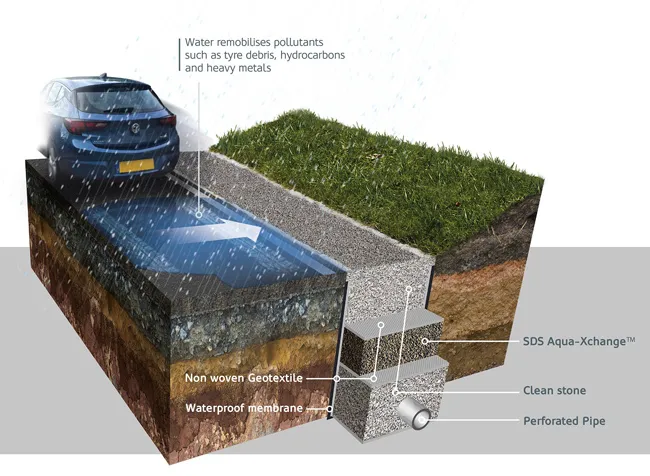

In a typical application, a layer of SDS Aqua-Xchange can be added as an additional component to a linear filter drain. Installed at a shallow depth, contractors avoid costly excavation or the use of heavy equipment.

SDS Aqua-Xchange can also be combined effectively with other proprietary SuDS devices. As it can filter out finer silts and sediments, it can be deployed downstream of a hydrodynamic vortex separator such as SDS Aqua-Swirl that targets larger particles. It can also be combined with geocellular storage, such as SDS GEOlight, when additional attenuation is needed as part of the roadside treatment system.

Compliant with guidelines in CIRIA C753 The SuDS Manual, SDS Aqua-Xchange can be included as a component in vegetative SuDS devices such as dry swales, raingardens or bio-remediation zones. The retention of copper and zinc is completely assured while plants can thrive.

The product helps tackle pollution problems caused by toxic metals carried in surface water runoff from roads and other heavy-traffic locations. Incapable of being broken down biologically, these metals would otherwise become attached to silts and sediments and dissolve in the runoff washed off hard surfaces during heavy rain.