Am ordinary inexpensive wire is permanently embedded into the concrete during pouring.

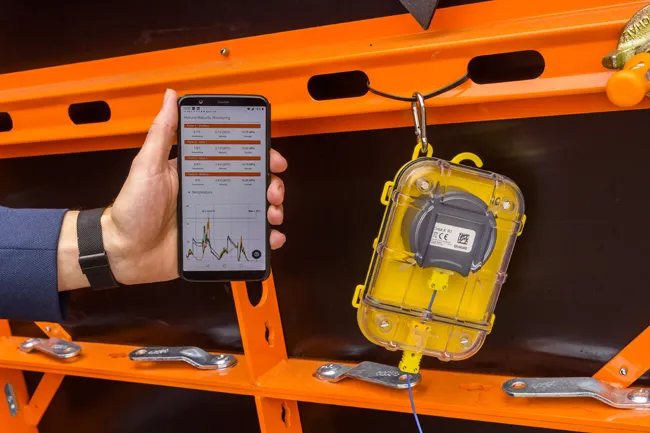

Concrete strength analysis and monitoring is carried out by wireless radio transmitters – this allows both improved planning and real-time monitoring independent of location and time, according to both companies.

The optimal time for dismantling formwork is determined. The user receives a convenient notification as soon as the target value has been reached or if there is too much difference in the internal temperature.

To guarantee the best possible concrete quality, the concrete temperature can be controlled and adjusted from any location by means of heating and cooling systems.

The Maturix software is a web-based application that can be accessed from anywhere.

When the concrete is cured and the formwork is to be moved, the wire is simply cut off close to the concrete face. A new wire is effortlessly installed into the measuring unit, ready to be embedded into a new pour as needed.

Applications for Maturix are many, says Rasmus Uhre, Maturix product manager. They include buildings, dams, bridges and even concrete roads.