Forming part of Mexico City’s transportation infrastructure development plan, this viaduct is 227m long and connects the residential and commercial area Interlomas with the Naucalpan-Toluca highway. ULMA designed a solution fully tailored to meet the pace and needs of the client: gantry falsework for two 59m outer spans, and a CVS Form Carrier for the central span of 108m.

ULMA’s engineering team combined robust OC Shoring with the Heavy Duty MK Shoring system to shore the deck at heights greater than 15m, adapting to the steep terrain. An MK Truss, placed between a pier and the MK Shoring assembly, covered a gap more than than 20m in length.

For the central span, the flexibility of the CVS Carriage made it possible to adapt to the irregular deck thickness, which ranges from 3.4-6.5m at the pier segment, even while ensuring rapid completion of the 4m bridge segments.

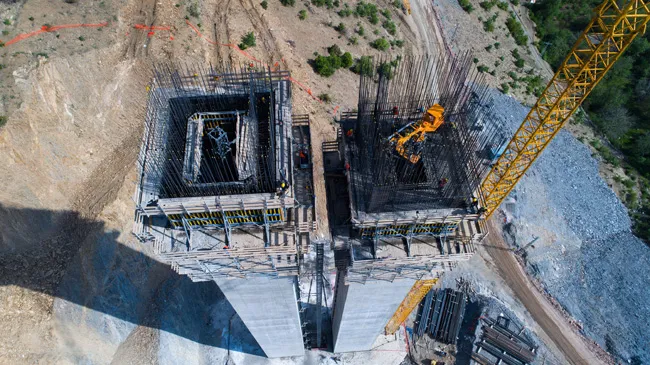

The two hollow piers with rectangular cross-section measure 42m in height, and were built in 5m segments with ENKOFORM V-100 formwork set on CR-250 roll-back climbing brackets. The advance carriages started work on both of the pier segments at the two extremes of the central span, advancing toward each other until meeting at the end segment.