A Herrenknecht S-574 Earth Pressure Balance Shield is being used on a major highway project in Italy.

February 13, 2012

Read time: 2 mins

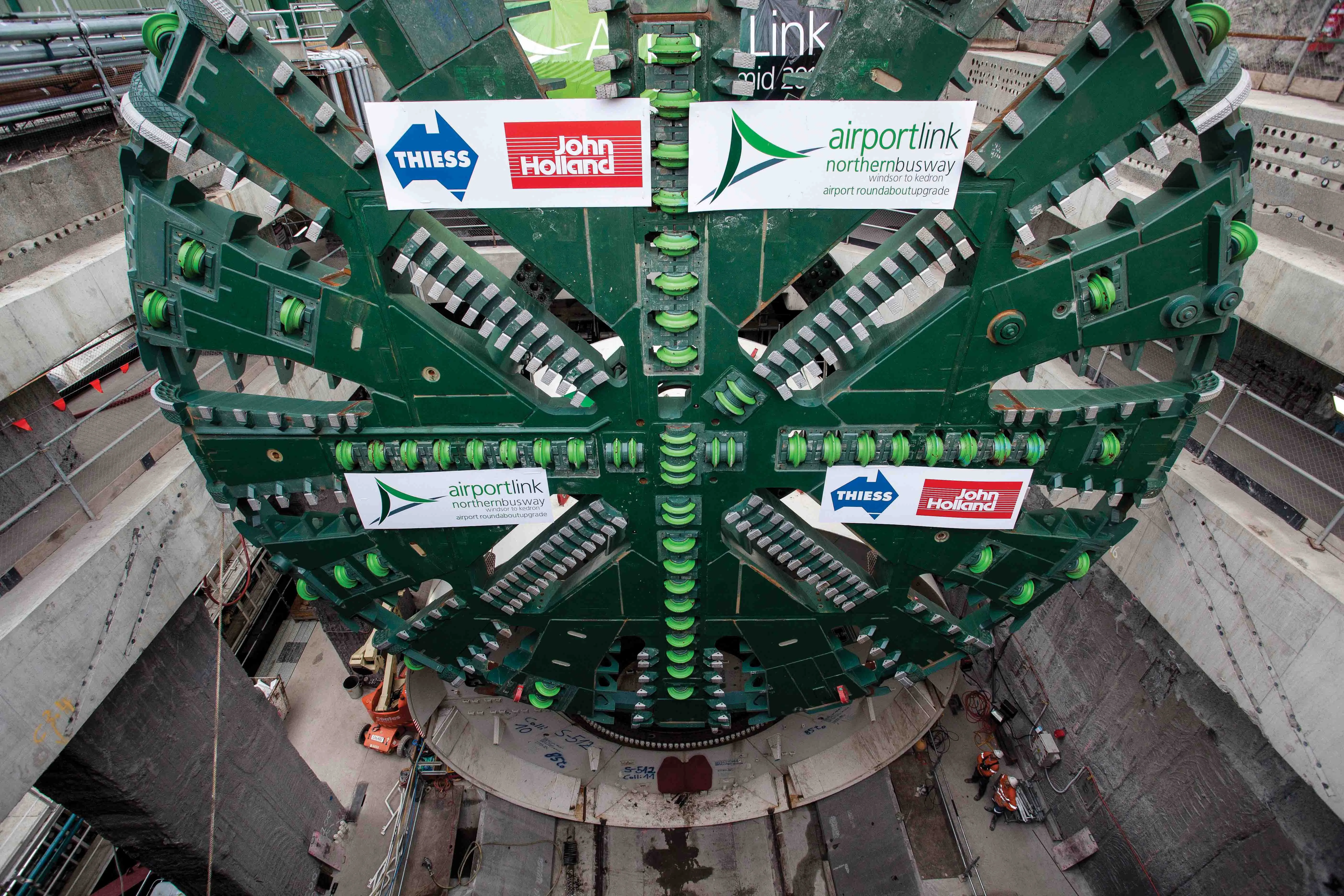

A 2592 Herrenknecht S-574 Earth Pressure Balance Shield is being used on a major highway project in Italy.

The machine was successfully accepted by the Italian customer at Herrenknecht's headquarters in Schwanau, southern Germany.

With an excavation diameter of 15.62m and an overall length of 130m, this giant is the largest tunnel boring machine (TBM) ever built and had to be partially dismantled for transport to the site in Italy.

With a total weight of 4,500tonnes, the TMB has installed power of 12,000kW; a maximum thrust force of 394,850kN (500 bar), and cutting wheel torque of 94,793kNm. The cutting tools include 76 discs, 216 cutting knives, 24 buckets and one centre knife.

The S-574 will be used on a busy section of the A1 highway between Bologna and Florence (the Variante di Valico project), which is currently being extended.

The development also involves the 2.5km twin-bore Sparvo Tunnel which is part of a project awarded by the Italian client3623 Autostrade per l'Italia to a joint-venture comprising 2589 Vianini Lavori, 6423 TOTO Costruzioni Generali and 2591 Profacta.

The Herrenknecht S-574 is to be used for mechanised tunnelling of this new large-diameter tunnel, having been assembled at Schwanau over a period of three months, and then extensively commissioned and tested.

The giant TBM is to start tunnelling the first tube near Florence in a northerly direction in May 2011 with plans for the new route to open by the end of 2013. It will significantly reduce the travel time between Bologna and Florence for up to 90,000 vehicles/day.

The Sparvo Tunnel, with a diameter of 13.6m, runs between Sasso Marconi and Barberino del Mugello, and is being constructed through clay, argillite and sandstone. With loose soil containing explosive firedamp anticipated along the 5km stretch, and to achieve a high degree of industrial safety and swift tunnelling performance, the building contractor opted for the EPB Shield from Herrenknecht.

The machine was successfully accepted by the Italian customer at Herrenknecht's headquarters in Schwanau, southern Germany.

With an excavation diameter of 15.62m and an overall length of 130m, this giant is the largest tunnel boring machine (TBM) ever built and had to be partially dismantled for transport to the site in Italy.

With a total weight of 4,500tonnes, the TMB has installed power of 12,000kW; a maximum thrust force of 394,850kN (500 bar), and cutting wheel torque of 94,793kNm. The cutting tools include 76 discs, 216 cutting knives, 24 buckets and one centre knife.

The S-574 will be used on a busy section of the A1 highway between Bologna and Florence (the Variante di Valico project), which is currently being extended.

The development also involves the 2.5km twin-bore Sparvo Tunnel which is part of a project awarded by the Italian client

The Herrenknecht S-574 is to be used for mechanised tunnelling of this new large-diameter tunnel, having been assembled at Schwanau over a period of three months, and then extensively commissioned and tested.

The giant TBM is to start tunnelling the first tube near Florence in a northerly direction in May 2011 with plans for the new route to open by the end of 2013. It will significantly reduce the travel time between Bologna and Florence for up to 90,000 vehicles/day.

The Sparvo Tunnel, with a diameter of 13.6m, runs between Sasso Marconi and Barberino del Mugello, and is being constructed through clay, argillite and sandstone. With loose soil containing explosive firedamp anticipated along the 5km stretch, and to achieve a high degree of industrial safety and swift tunnelling performance, the building contractor opted for the EPB Shield from Herrenknecht.