The system is said to provide precise and productive workflows for demanding survey and construction applications. The units can lay out or survey more points precisely and in less time than previous generation tools. Meanwhile, the units also improve quality and consistency.

These digital tools are said to be easy to use and offer accurate and repeatable results, for less rework and better quality control. The units are compact and are said to be easy to transport onsite, while their versatility means that they can be used for layout, survey and machine guidance duties.

Key features include precise positioning and single-person operation, high-speed advanced ultrasonic motors and easy to use MAGNET or Pocket3D software, as well as seamless integration into BIM workflows. The units are available in GT-1200 and GT-600 models with multiple accuracy levels and are offered with a three-year instrument and five-year motor warranty. Designed for use in tough construction site duties, the units are rugged and offer IP65 dust and water resistance. The UltraTrac prism tracking technology offers reliable performance and the units are said to maintain work pace with the total station locked onto the prism, even in challenging environments.

These tools can help in kerb and gutter jobs by maintaining productivity and accuracy when facing GPS coverage issues. Using either the GT-1200 series robotic total station or the LN-150 robotic layout navigator, customers can augment their existing Millimeter GPS concrete paving solution, and remedy issues such as foliage canopies, large buildings, tunnels and overpasses.

Both instruments offer support for a prism solution that can switch quickly between Millimeter GPS and local positioning systems (LPS). Both use Topcon LongLink communication for connectivity. The self-levelling LN-150 is an easy-to-use, cost-effective robotic solution while the GT-1200 series instruments can perform a full range of functions as a standalone surveying total station.

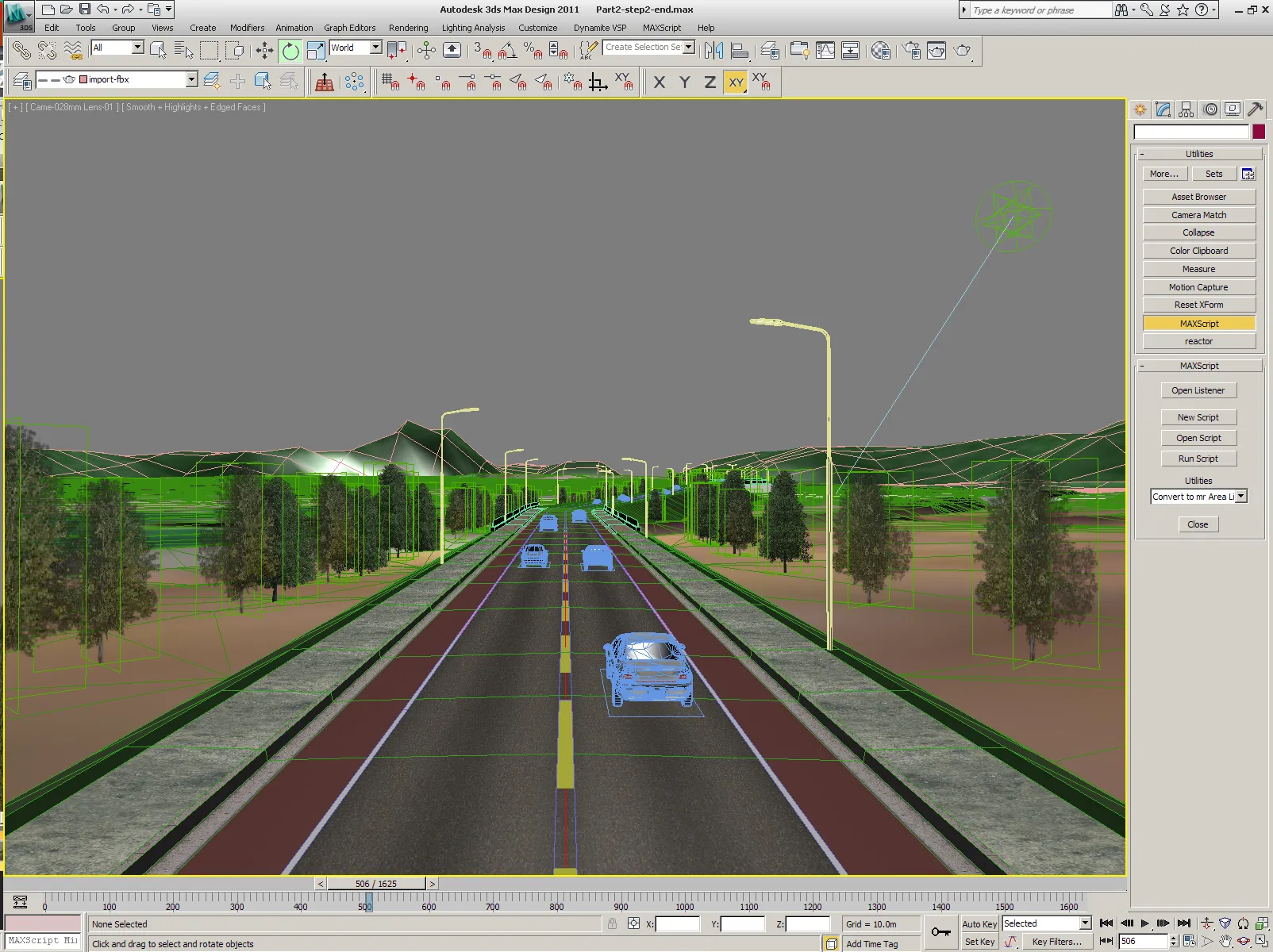

The tools allow precise 3D layout and have an easy to use, self-levelling setup as well as Wi-Fi and long-range Bluetooth options. The units offer cloud-connected workflows with Autodesk, Bentley, and MAGNET software, including the MAGNET Construct mobile app for phone or tablet.